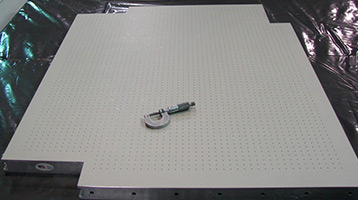

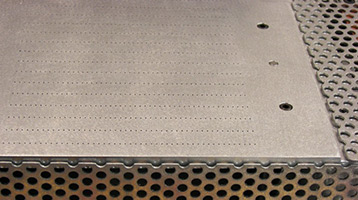

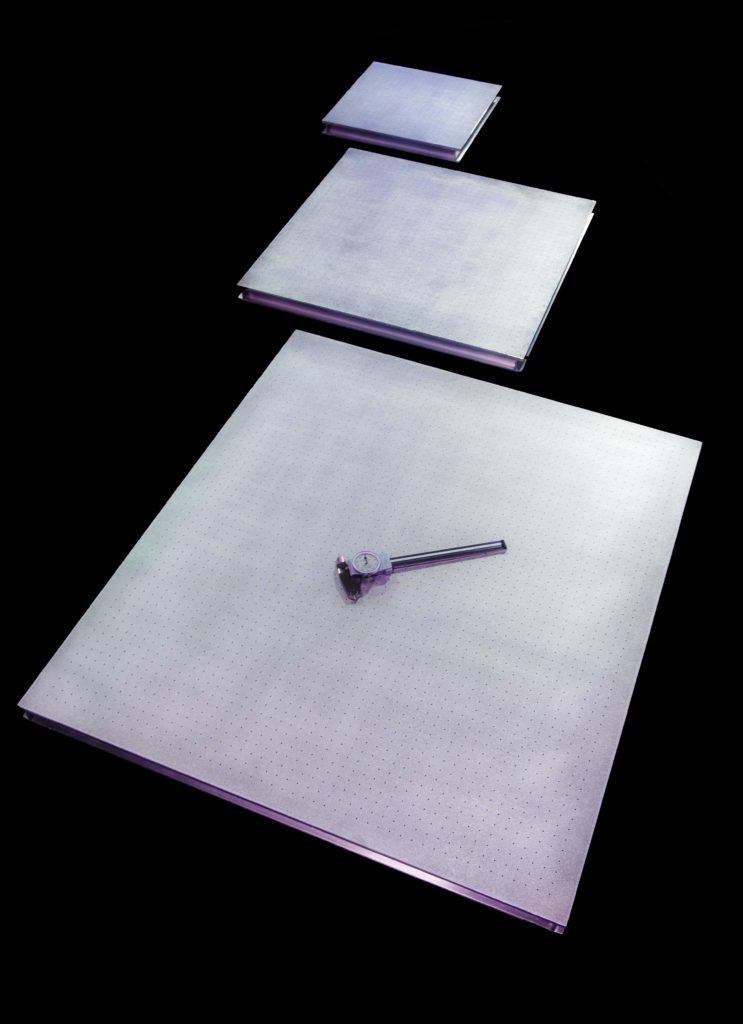

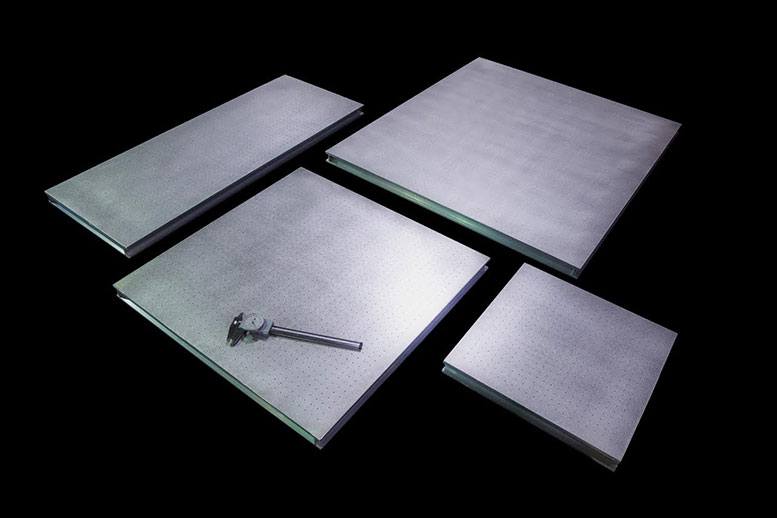

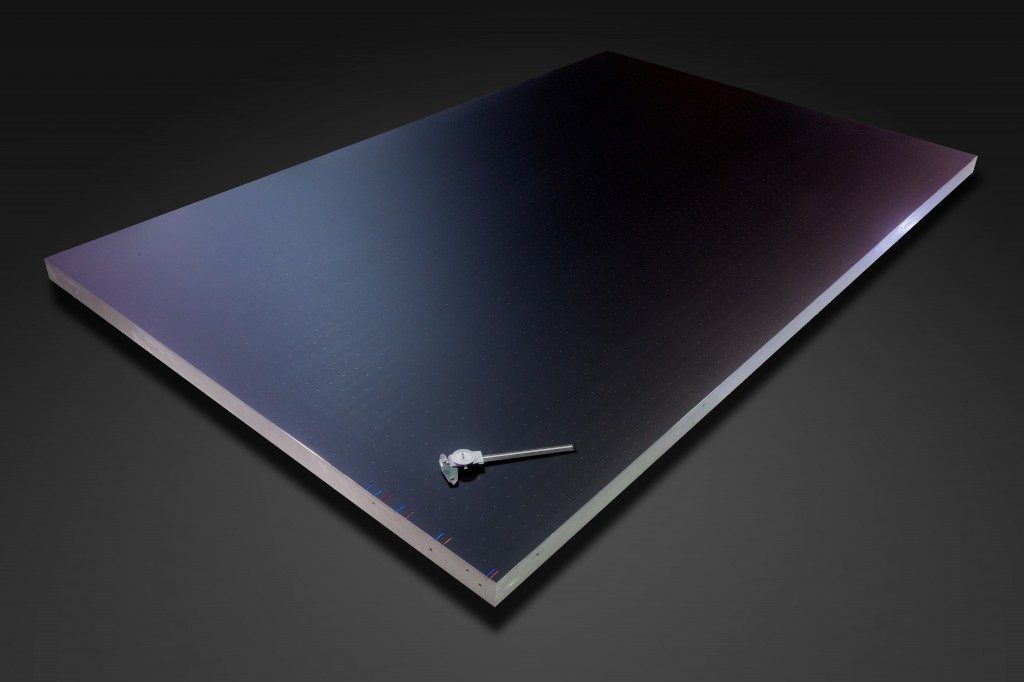

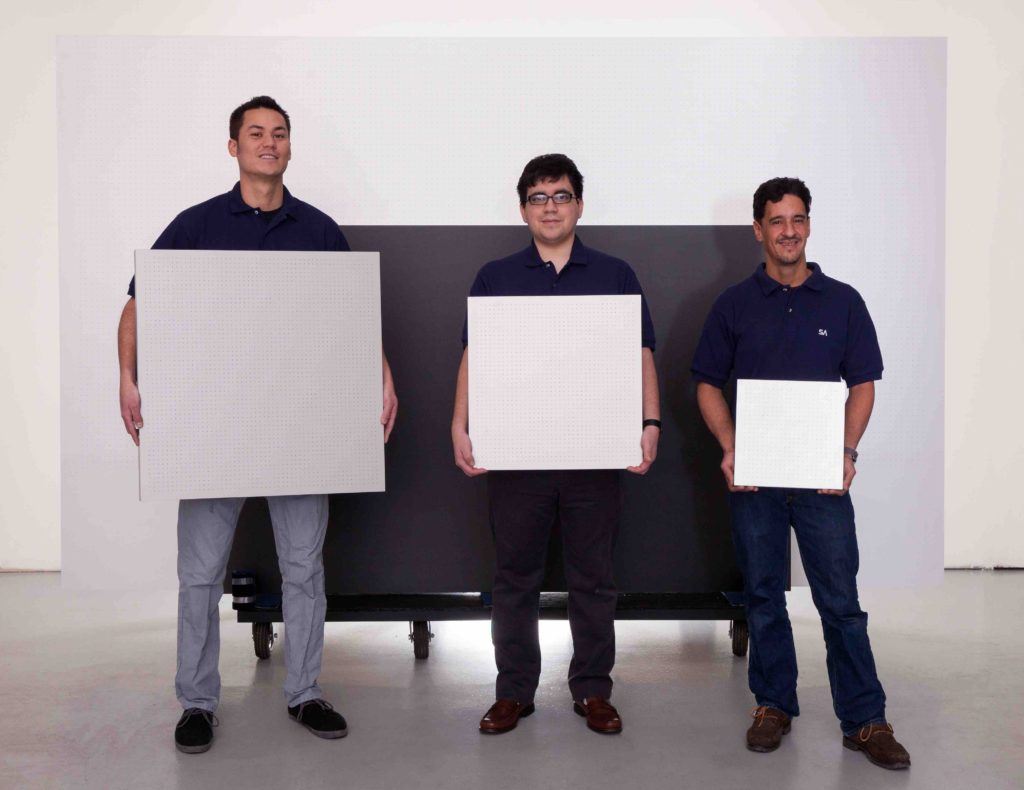

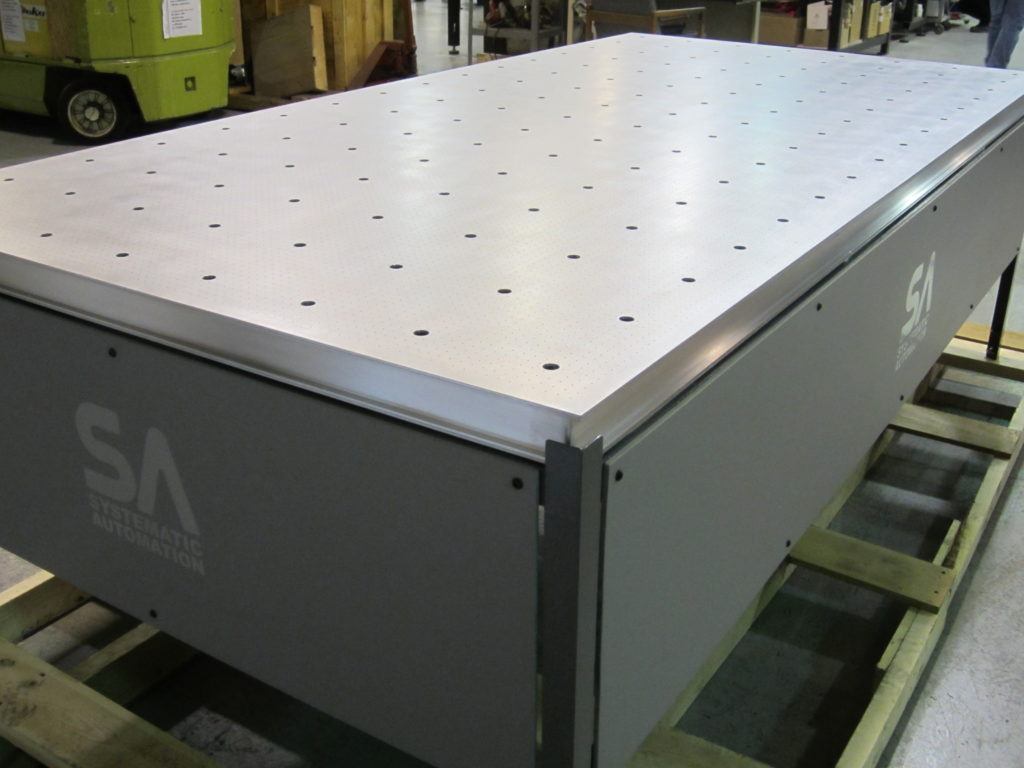

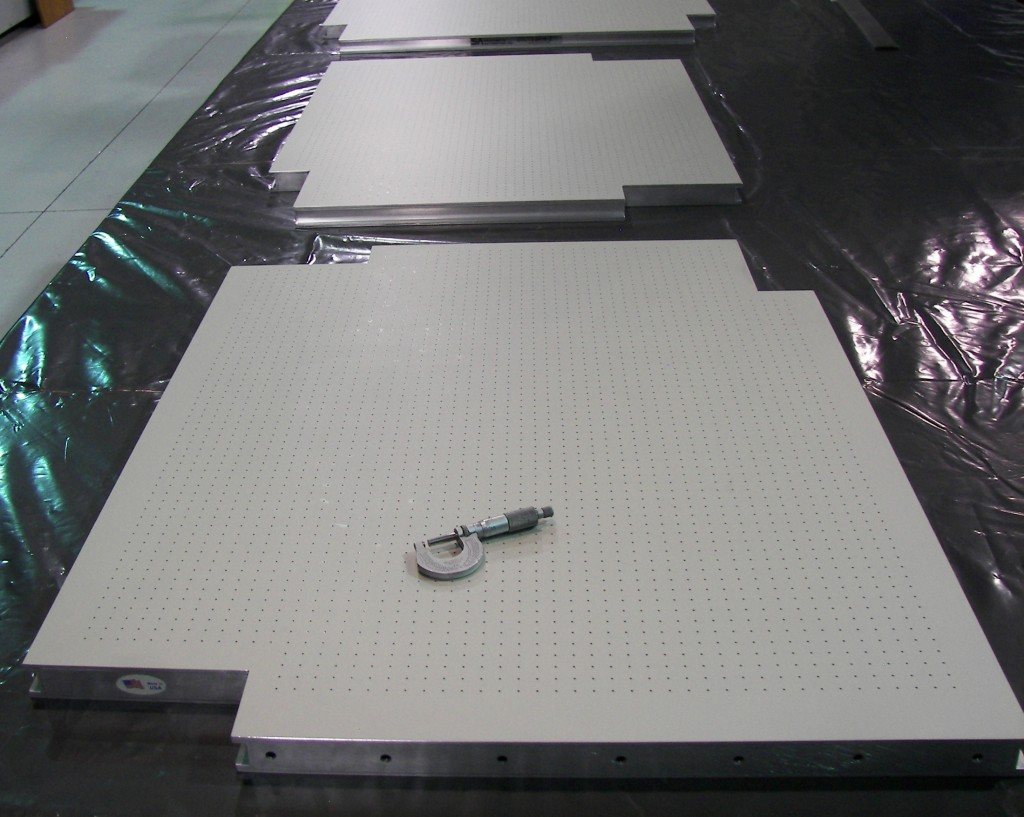

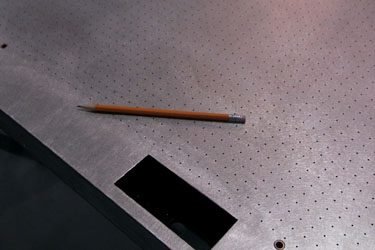

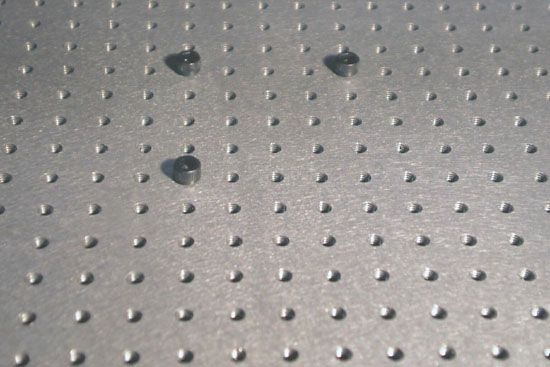

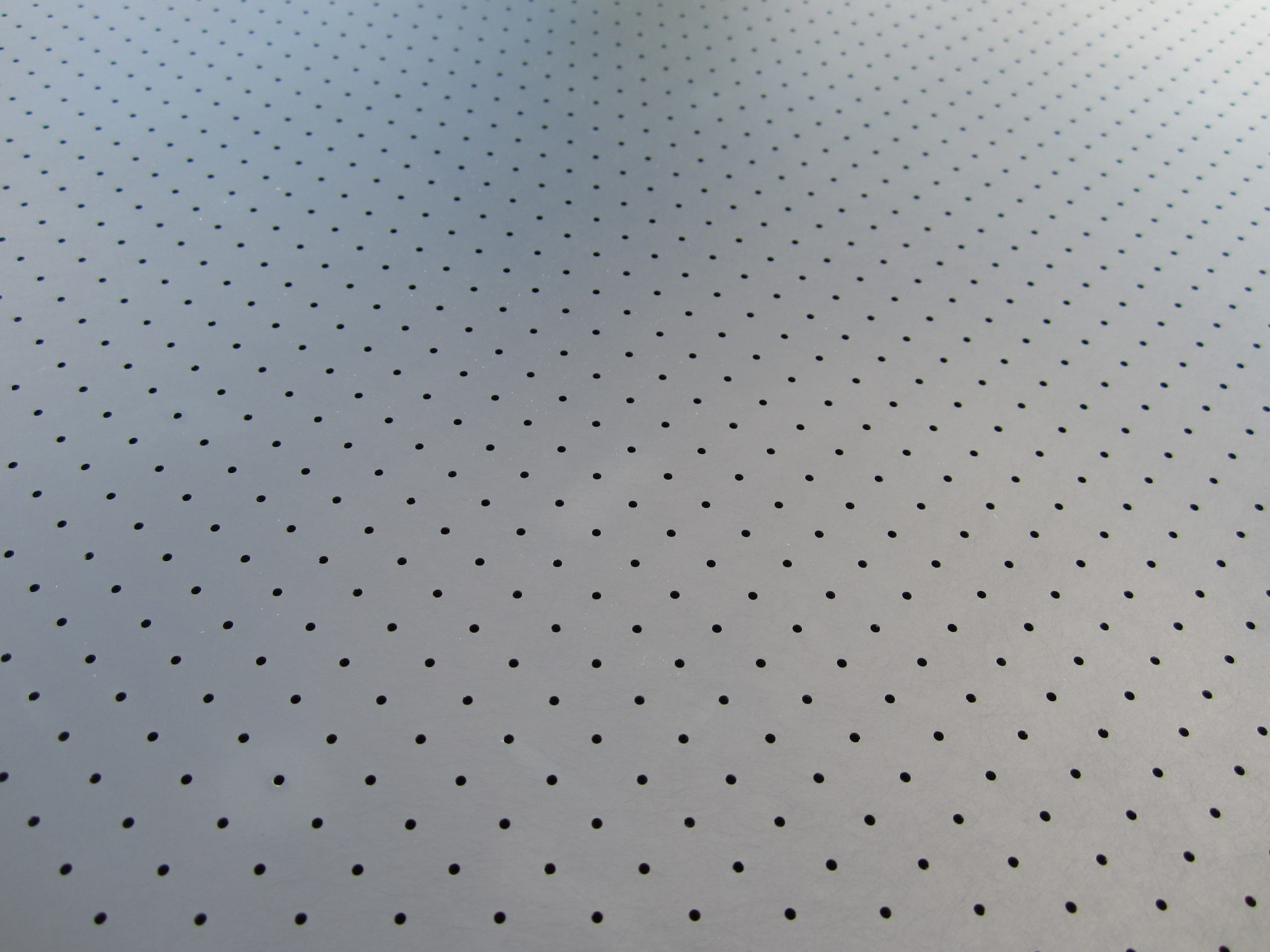

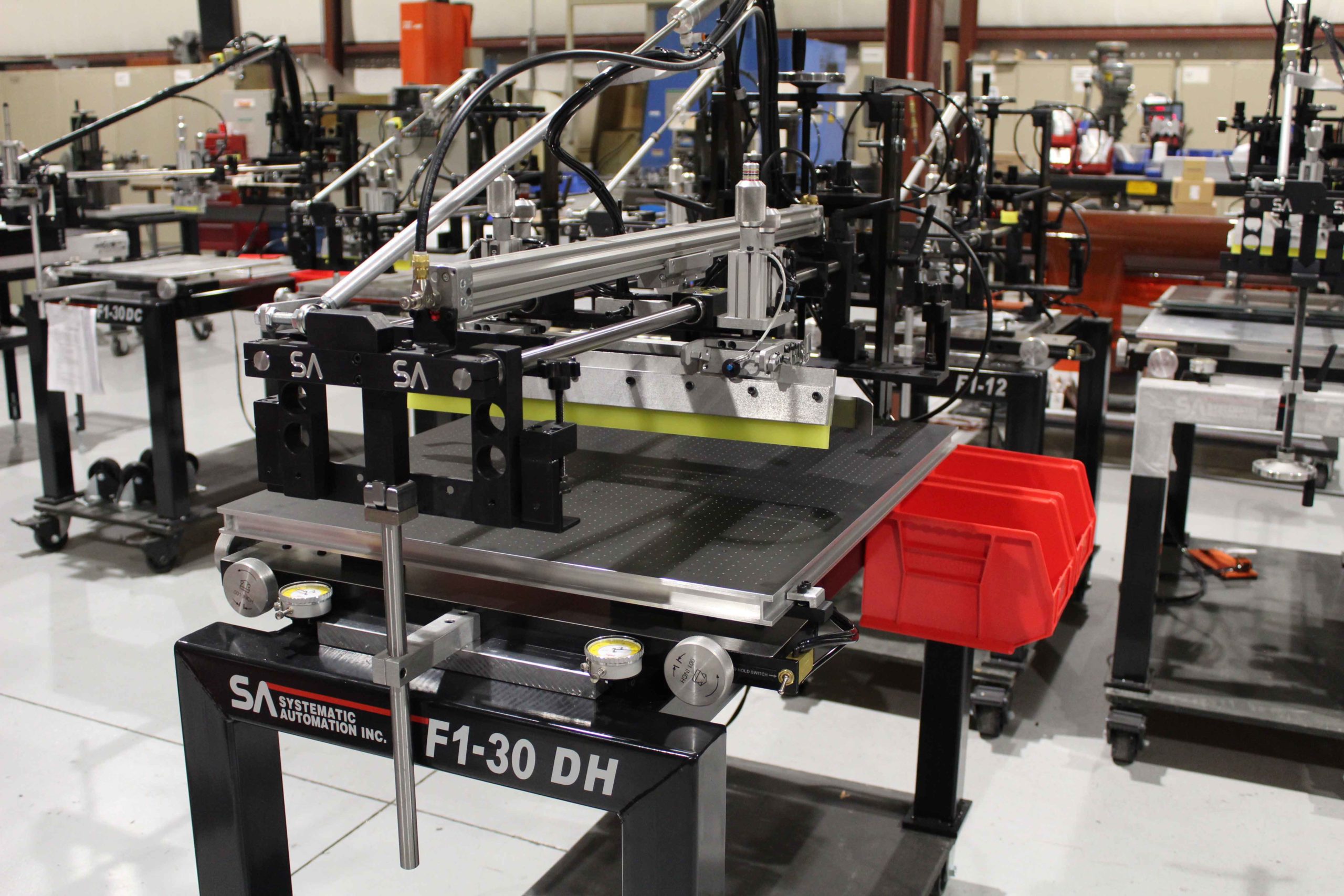

Industry Leading Flatness

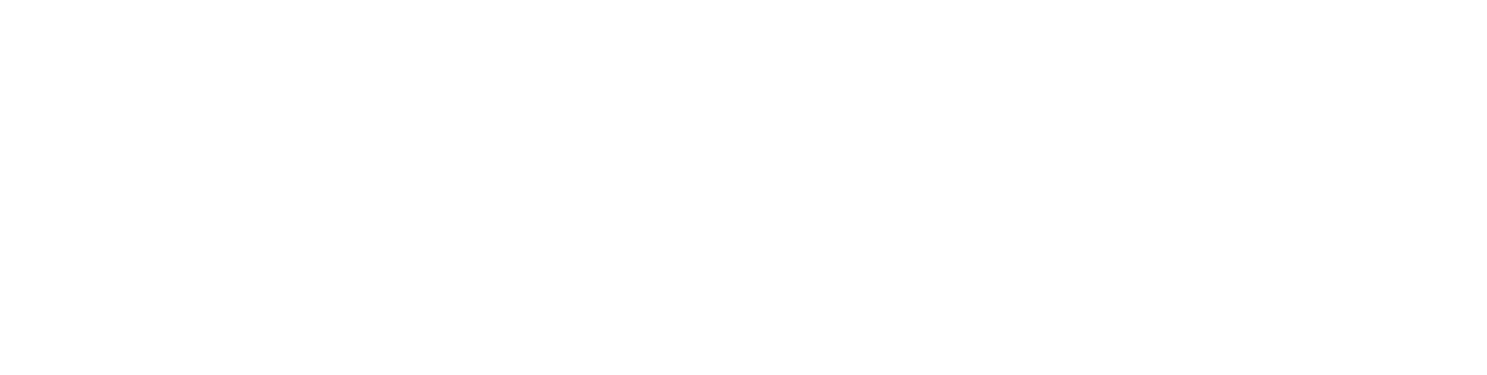

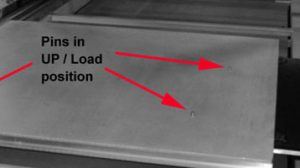

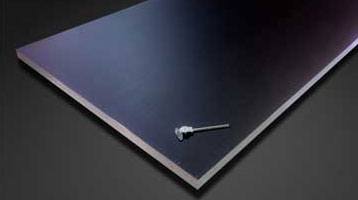

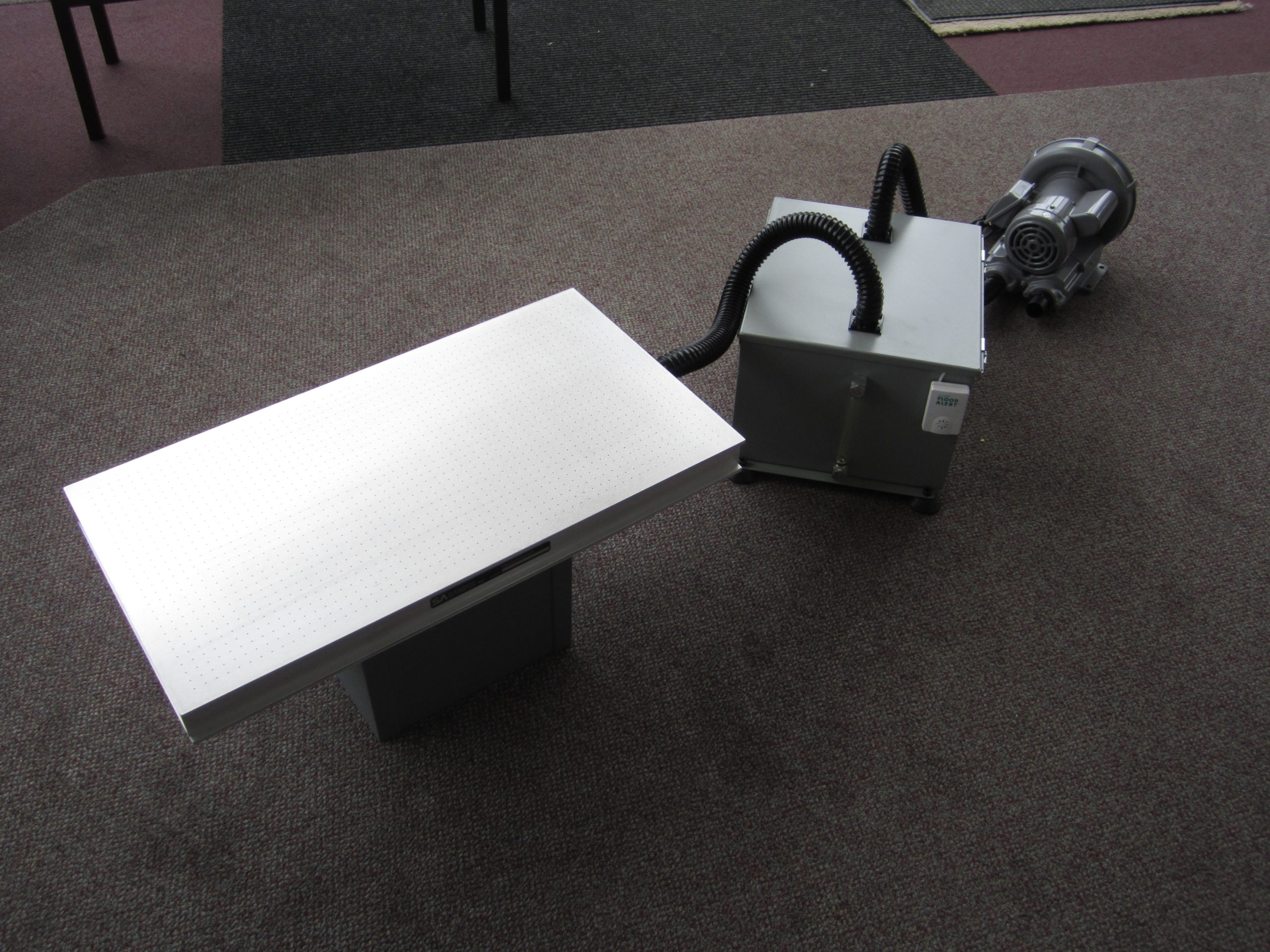

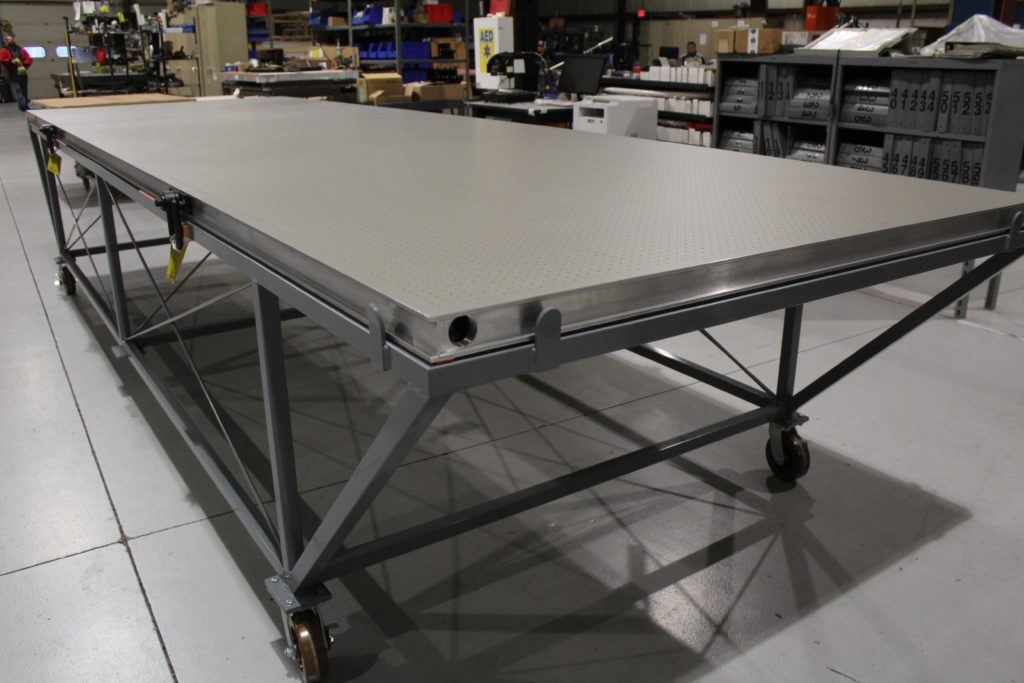

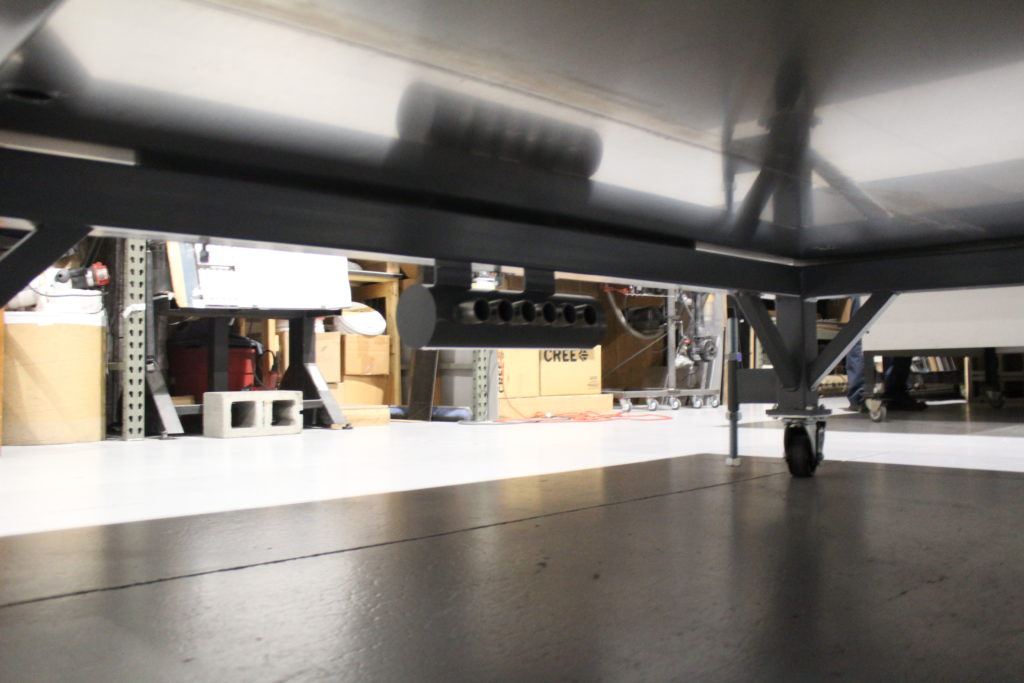

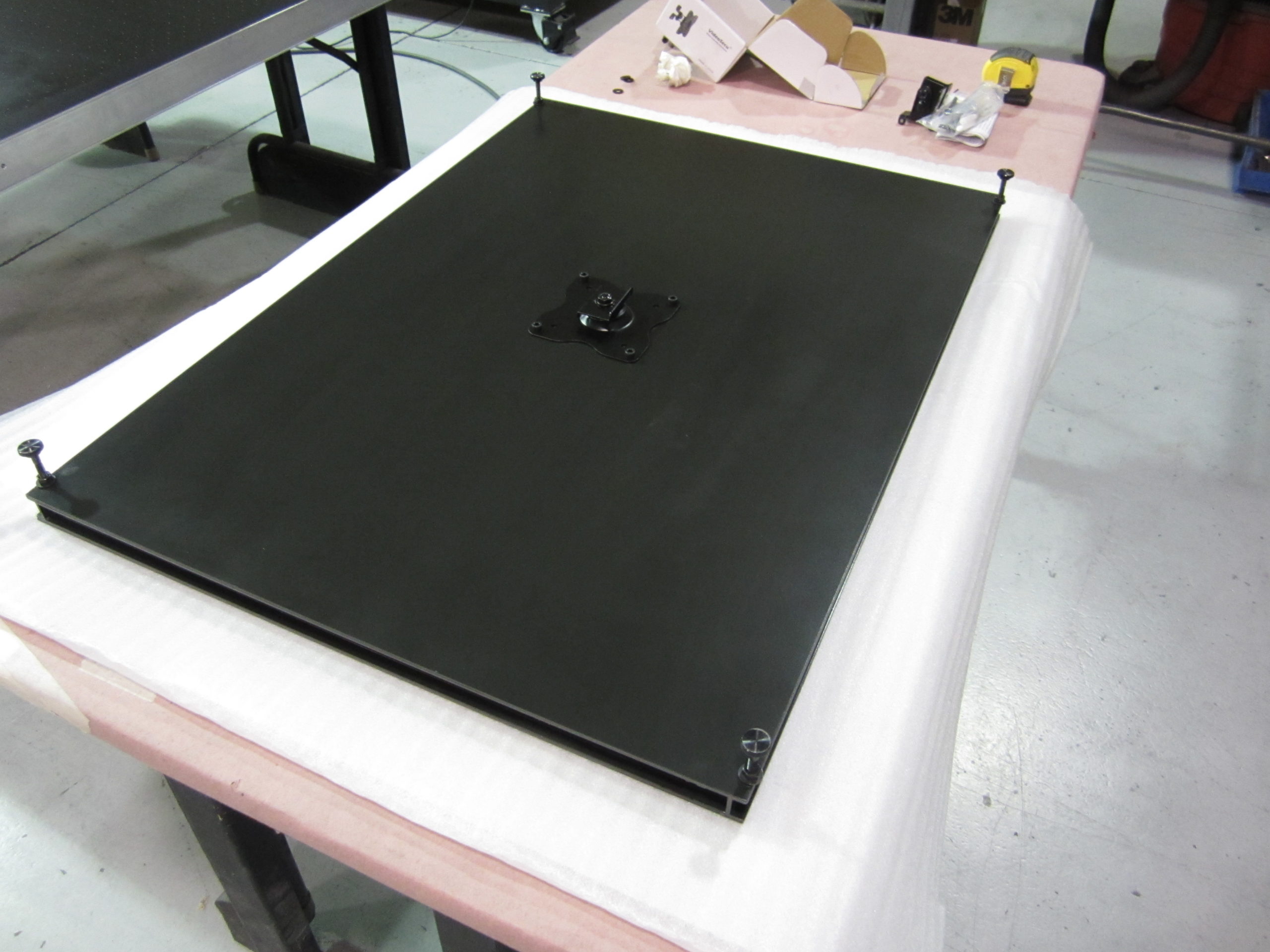

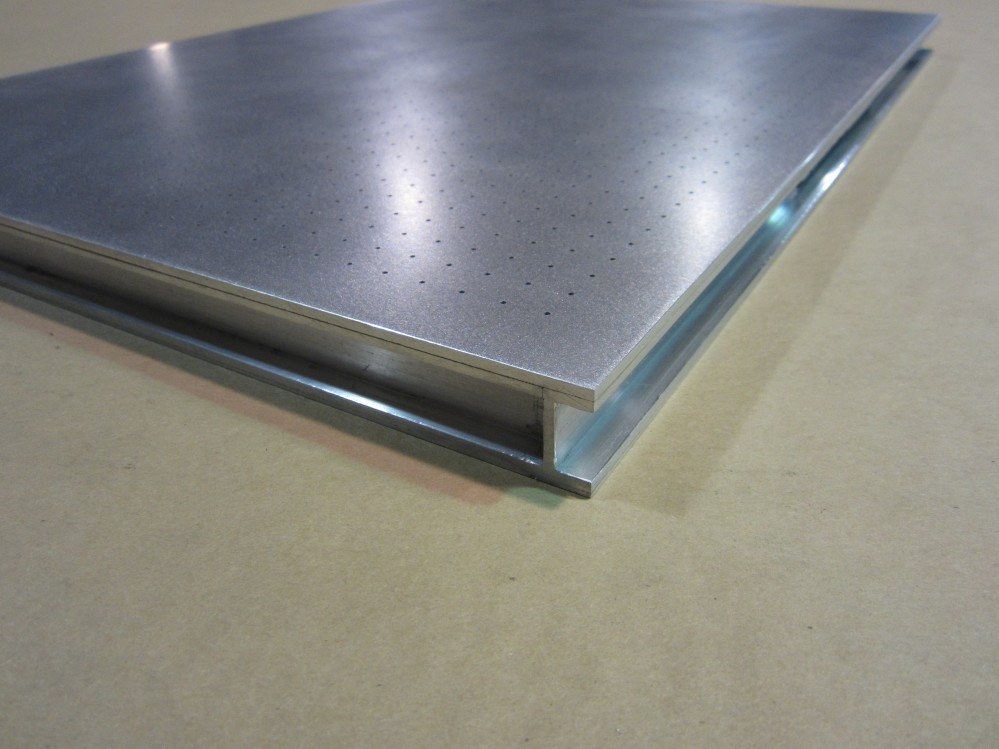

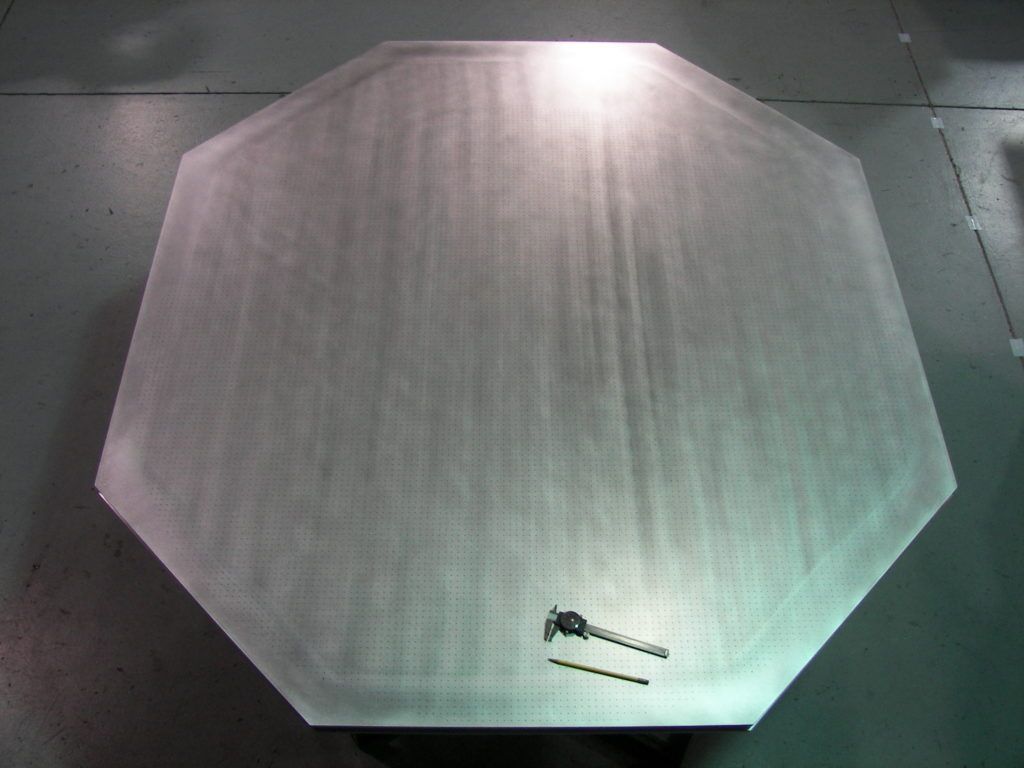

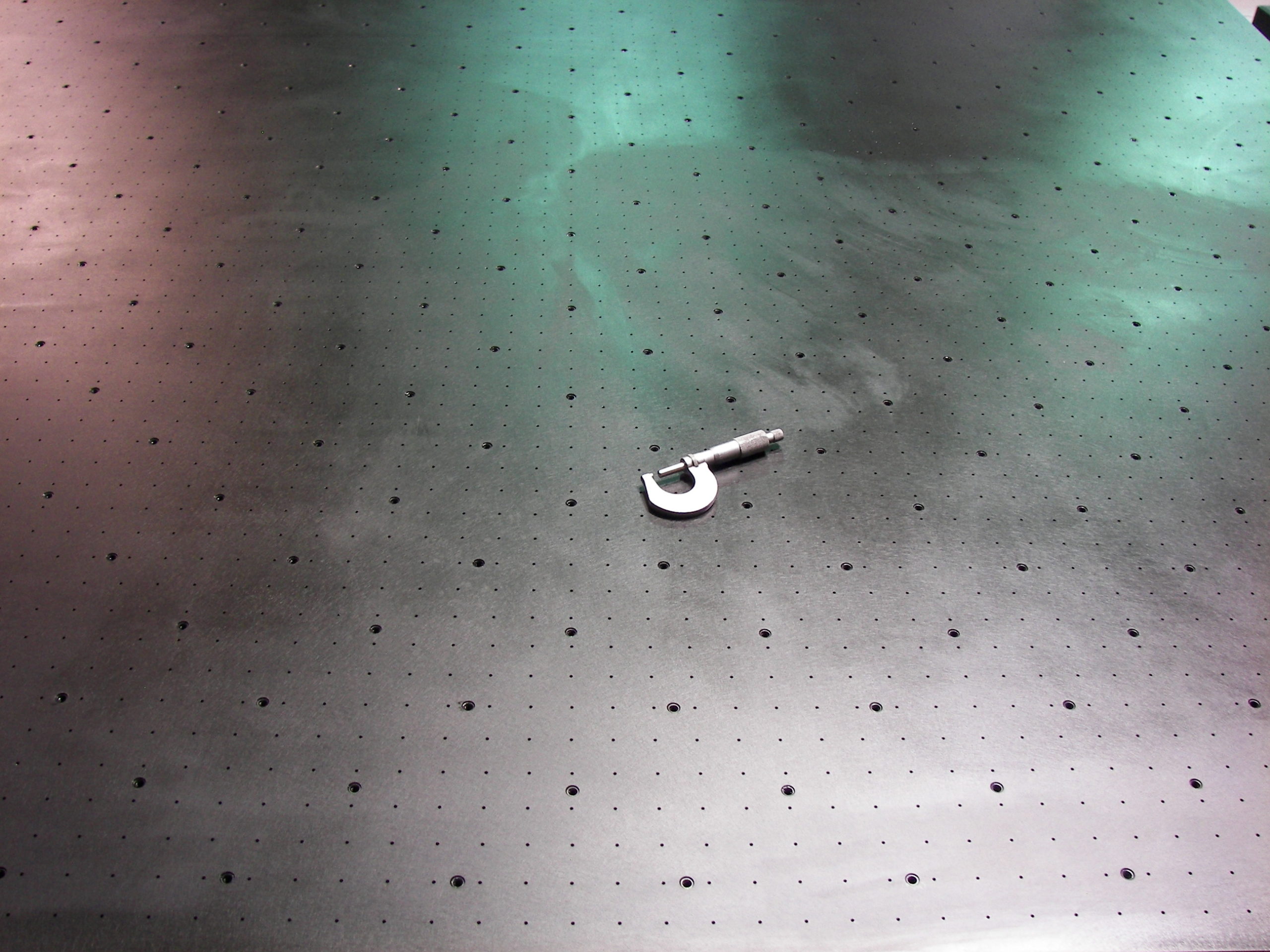

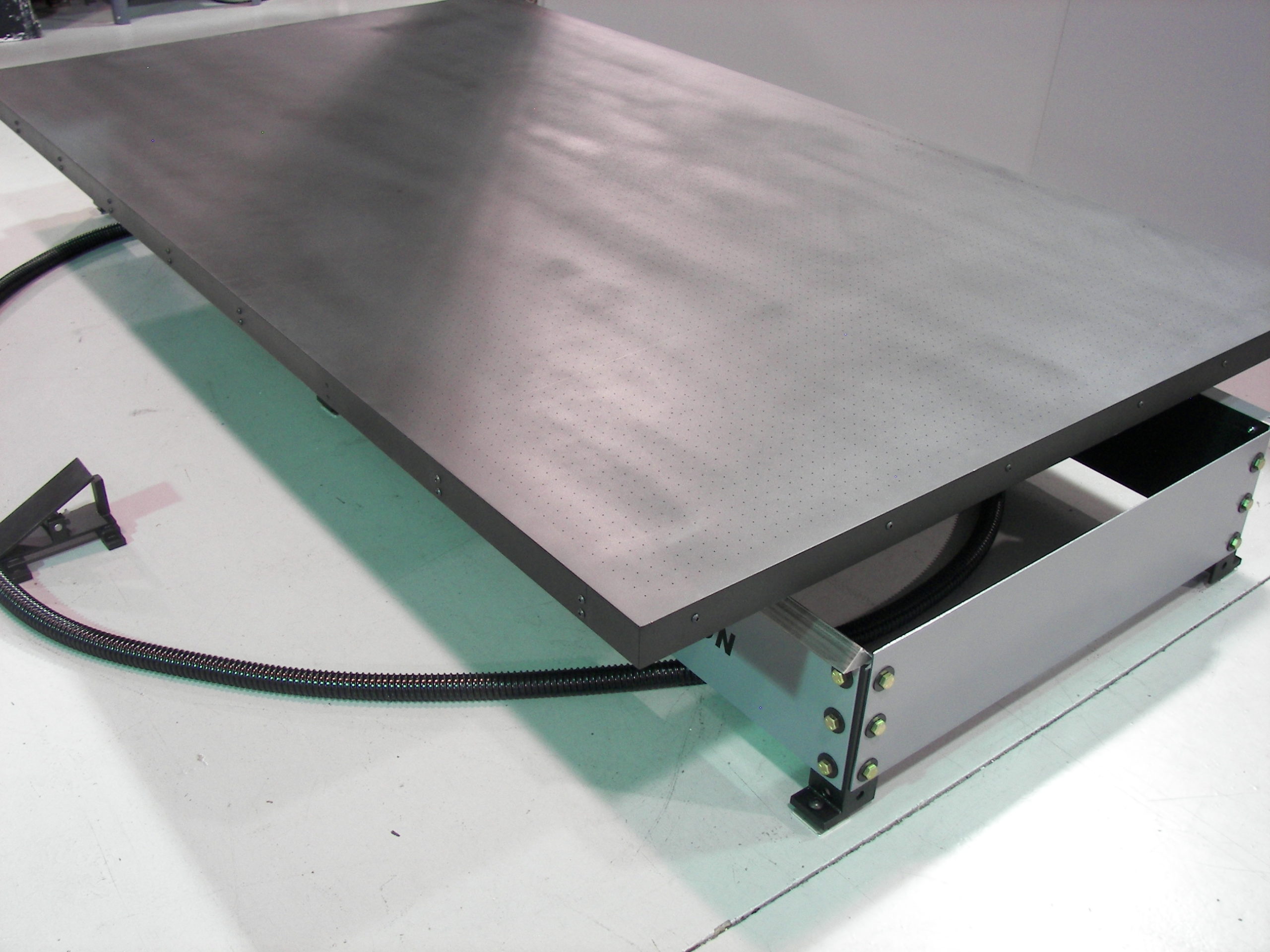

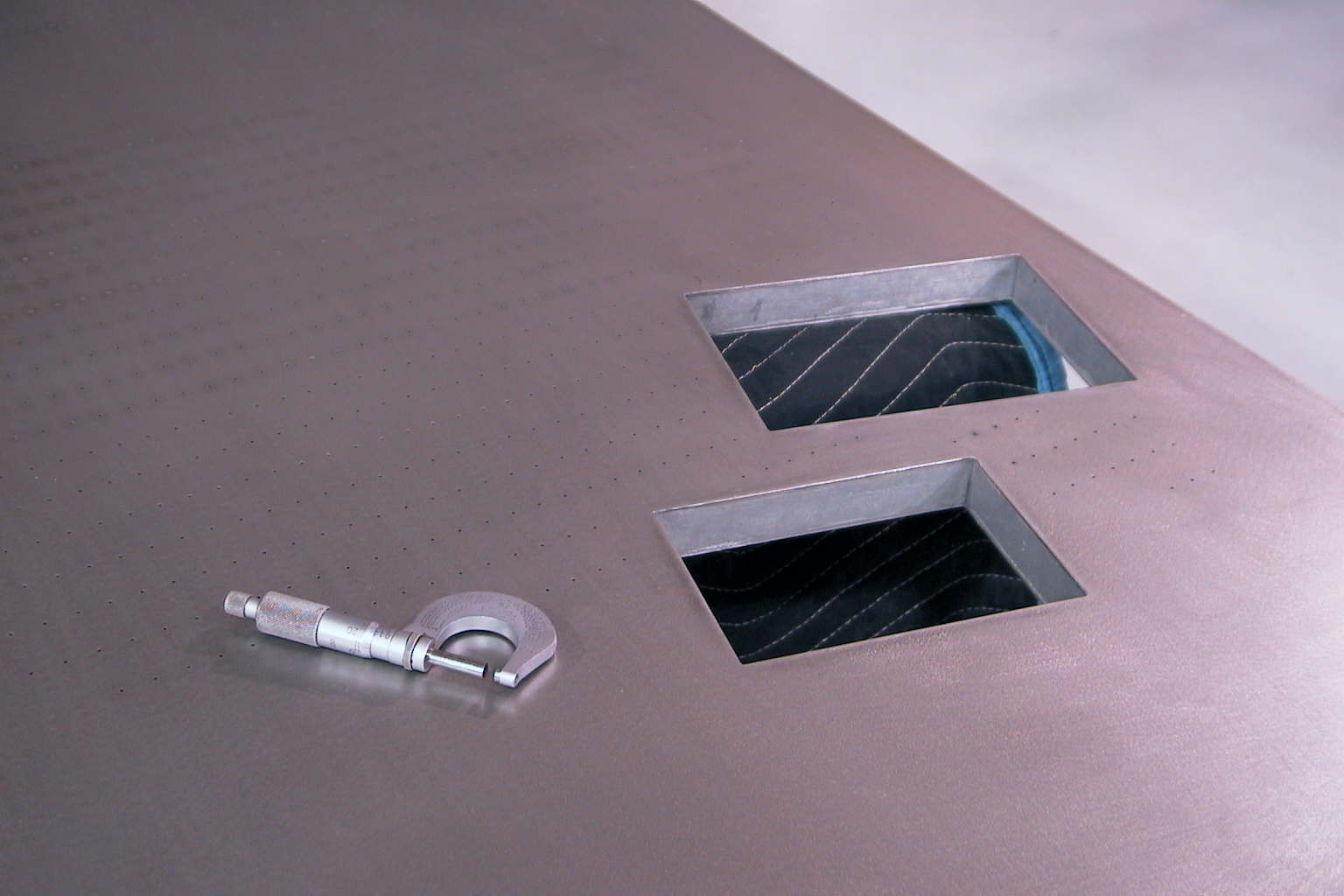

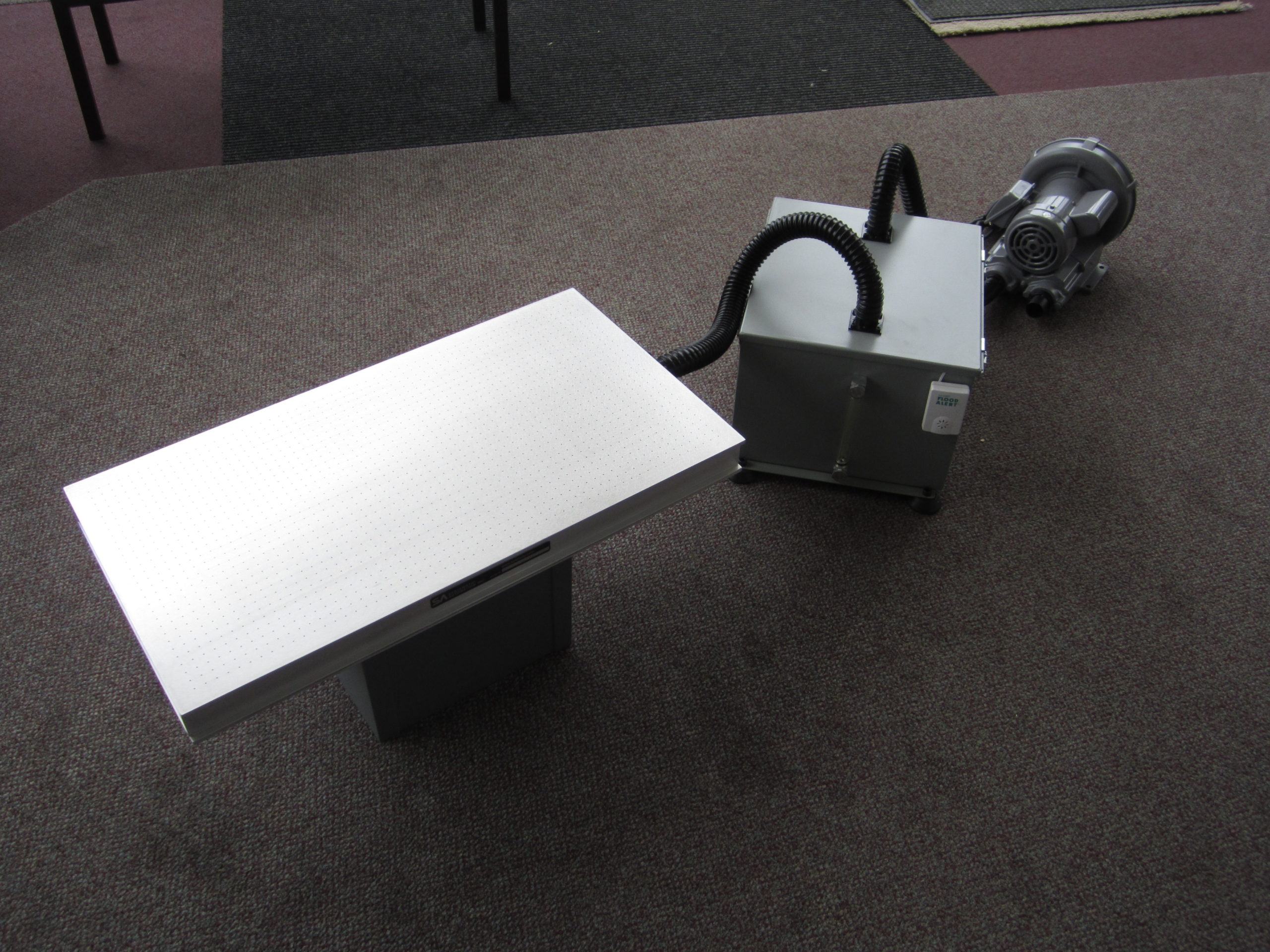

Systematic Automation, Inc. provides proven vacuum table solutions with proprietary and patented technology. All vacuum tables are inspected before shipment to ensure it reaches our precision flatness standard of +/-.001″ per linear foot. Contact us today for proven solutions from the world’s largest manufacturer of vacuum tables.

Systematic Automation employs a highly skilled staff with in-depth knowledge of how to customize a vacuum table system for your specialized process. We provide continual support and professional customer service for all vacuum table solutions. Vacuum tables are manufactured custom to your specification.

Diverse Industry Knowledge

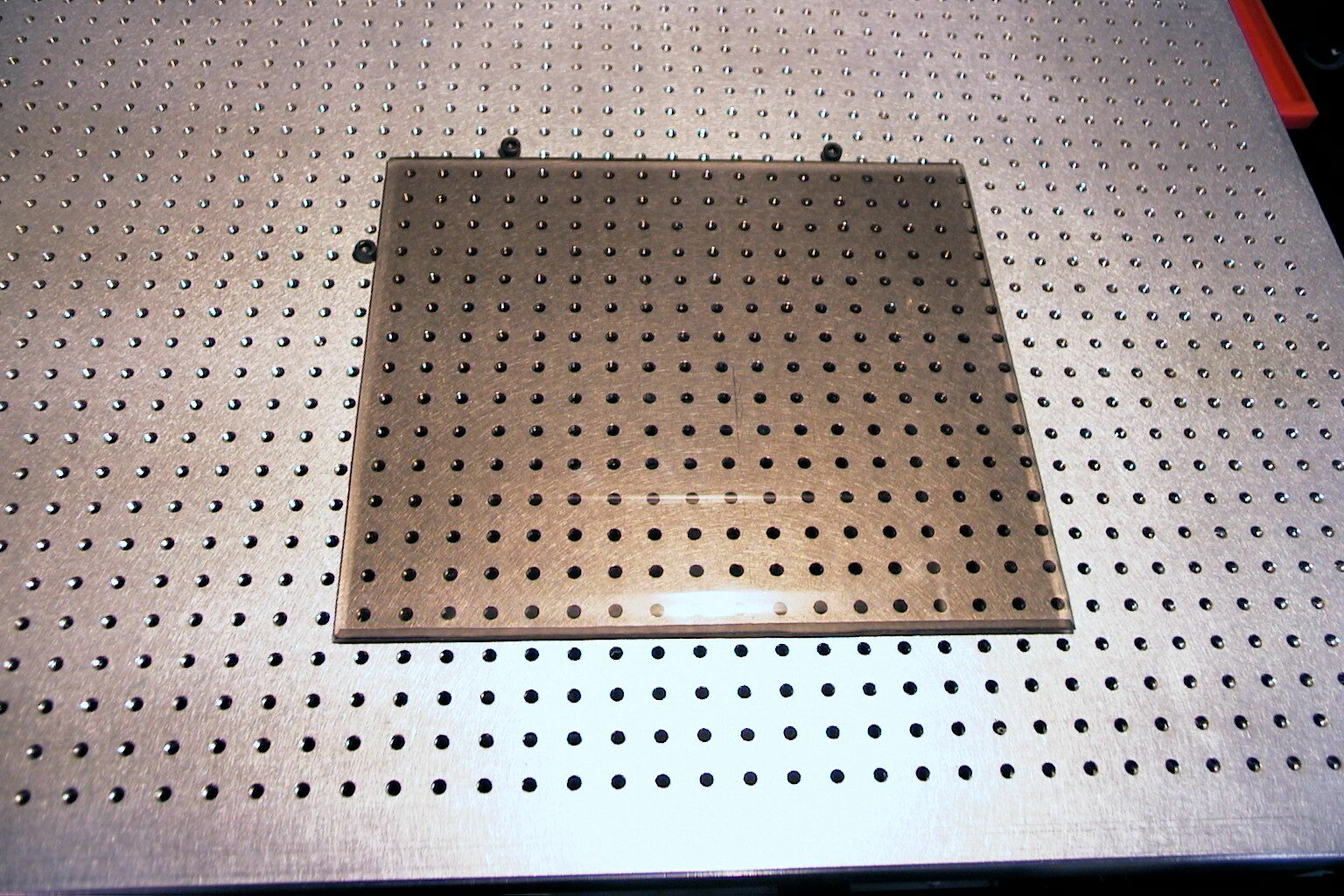

We have a full line of precision vacuum tables used in a wide array of industrial applications worldwide. Vacuum tables are used in screen printing processes to securely hold the substrate in place while performing printing or curing processes. This ensures a consistent printing process with complete coverage, dramatically improving product quality.

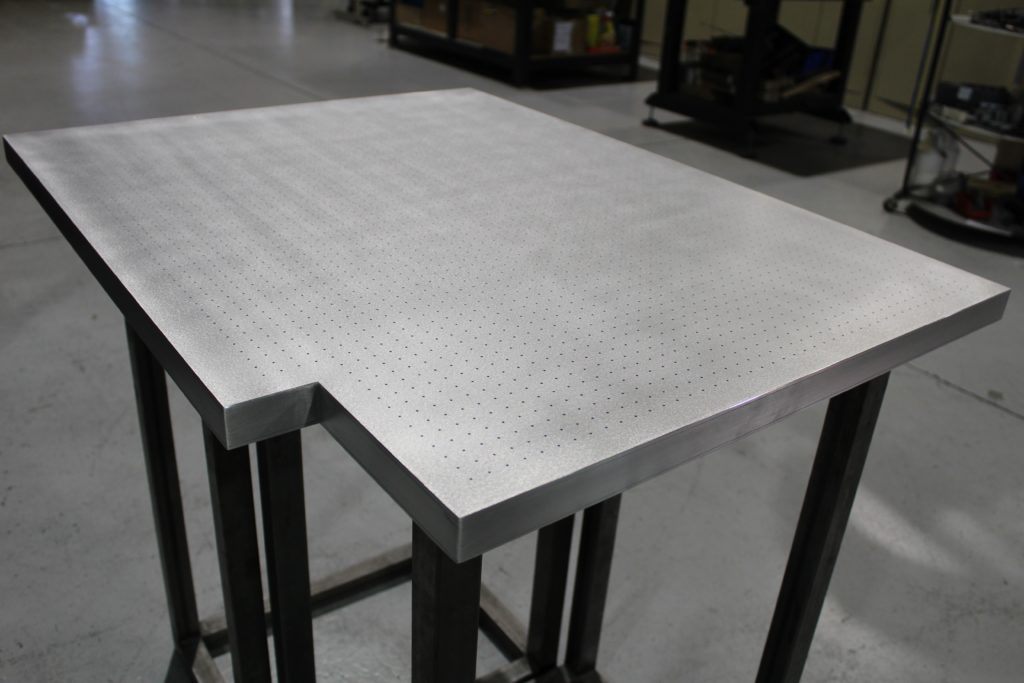

Vacuum tables are also used in highly specialized commercial applications such as CNC machining, ultrasonic cutting, and UV curing for OEMs worldwide in various industries such as automotive and aerospace. The use of vacuum tables in these applications helps to maintain part integrity and meet or exceed customer specifications.

We are the world’s largest manufacturer of precision vacuum tables for many applications. Select an application to learn more:

- Assembly / Alignment Tools

- CNC Machining

- Surface Grinding

- Cutting Systems

- Die Cut Sheet Weeding Stations

- Flatbed Digital Printers

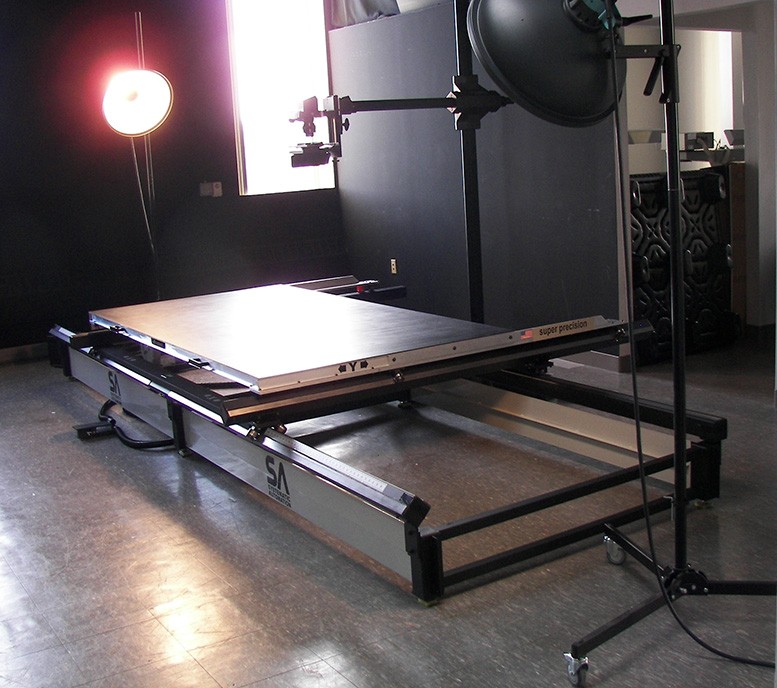

- Easels for Photography and Fine Art

- Flexographic Printing

- Heated Vacuum Tables

- Engraving

- Aluminum Honeycomb Panels

- Flatbed Inkjet Printers

- Library Digitization

- Lamination

- Papermaking

- Clean Room Application

- Aerospace

- Photo Stitching

- Plotter/Cutter

- Battery & Fuel Cells

- Thermoforming

- Sail Making

- Screen Printing Machines

- Staging Table

- Ultrasonic Cutting Machines

- Vision Inspection

- Glass Surface For UV Exposure

- Scanners

- Rug and Carpet Cleaning

- Wooden Vacuum Tables

We set the industry standard for flatness, customization, quality, and price

Systematic Automation is an expert manufacturer of vacuum tables, leading the industry with proprietary technology and setting the standard for superior, precision vacuum tables. Our knowledge and resources allow us to provide the best value to you with a high-precision vacuum table at the lowest possible cost. Our highly skilled staff and expert engineers provide world-class automated solutions with standard or customized vacuum table systems.

SOME OF OUR SATISFIED CUSTOMERS

Enhancing Inkjet Printing Adhesion: The Fierosil System Revolutionizes Drinkware Treatment

For drinkware printing, ink adhesion is paramount. Whether it’s intricate designs on packaging or vibrant graphics on marketing materials, achieving optimal print quality requires preparation, especially when it comes to printing on drinkware that will be repeatedly go through the dishwasher. Inkjet printing on drinwkare demands a delicate balance of substrate treatment to ensure ink…

Read MoreThe Significance of Silica Pretreatment

The Fierosil Silica Pretreatment System will provide your images with opaque, durable and cost effectiveness results . Silica pretreatment stands as a cornerstone process, offering a myriad of benefits that elevate the quality and durability of printed designs. In this article, we delve into the importance of silica pretreatment before screen printing and explore why…

Read MoreYour Everyday Devices: Screen Printing with Conductive Ink

In the dynamic world of electronics manufacturing, innovation knows no bounds. One such revolutionary advancement is the utilization of conductive ink in screen printing—a technique that is reshaping the landscape of electronic product design and production. In this article, we delve into the fascinating realm of screen printing with conductive ink, exploring its diverse applications,…

Read MoreScreen Printing Inks for Plastic Cups

what are the best screen printing ink for plastic cups. When it comes to branding your business, one of the most effective ways to do so is by using custom printed plastic cups. These cups not only serve as a functional item for your customers, but they also act as a walking advertisement for your…

Read More