Fierosil - SILICA Pretreatment System

Pretreatment system for INDUSTRY STANDARD ink adhesion AT $24,000

Over 40 years of experience is available to you. Standard low cost solutions entirely made in USA. Fierosil has been tested domestically and abroad for ink adhesion with commercial dishwashers on drinkware. Results surpass the competition.

With the increased demand for an American made pretreatment system, our engineers developed an easy to use solution. The Fierosil is a next generation pretreatment tool that you will be proud to bring to your shop floor. It has universal success with industry standard inks such as Marabu, Saati, Ruco, Nazdar and with inkjet machinery. Contact us for a live demonstration, or to speak with an application engineer. FieroSil systems and supplies are in stock and ready for immediate delivery from our factory in Connecticut USA.

Testimonial

I inspect all orders, and I pay special attention to the beer growlers because UV ink does not want to stick onto the glass beer growlers, the reason is because the glass is so low end and crappy, ink just does not want to stick…. Then I ask my operator how she pre-treated: operator says with the new Fireosil system. I scratch onto the ink, and it’s bulletproof.

- Murray, Buccaneer Inc.

ENGINEERING FEATURES

Fierosil Operation

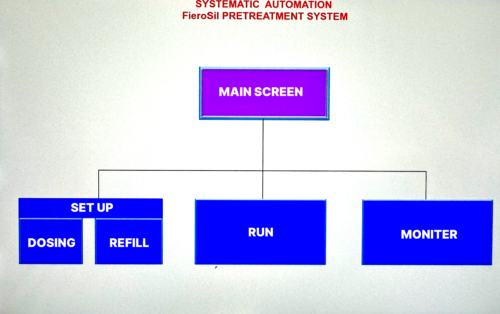

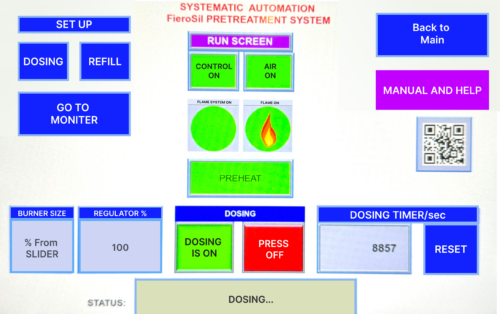

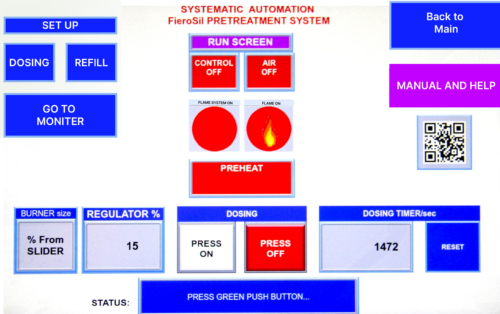

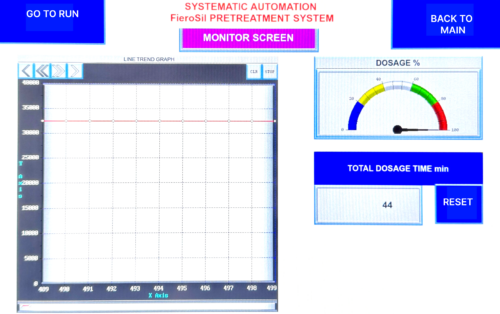

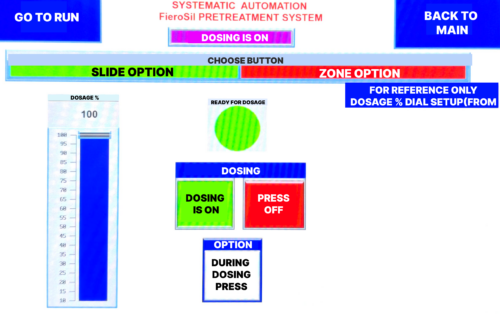

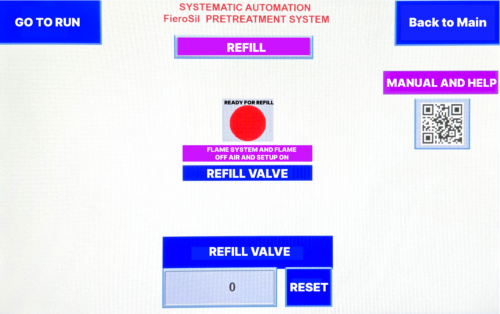

Touch Screen Controls

Fierosil Pretreatment Integration

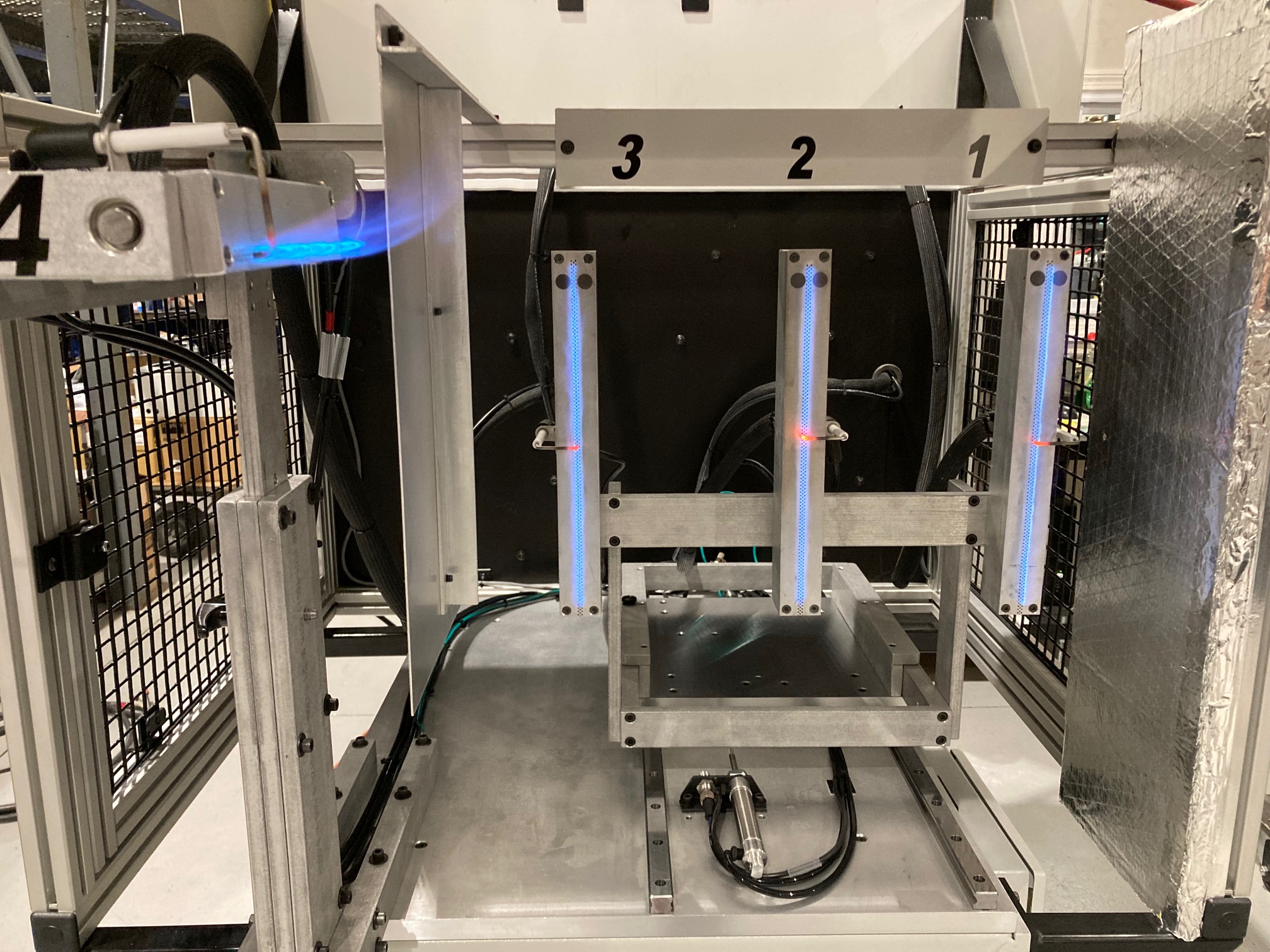

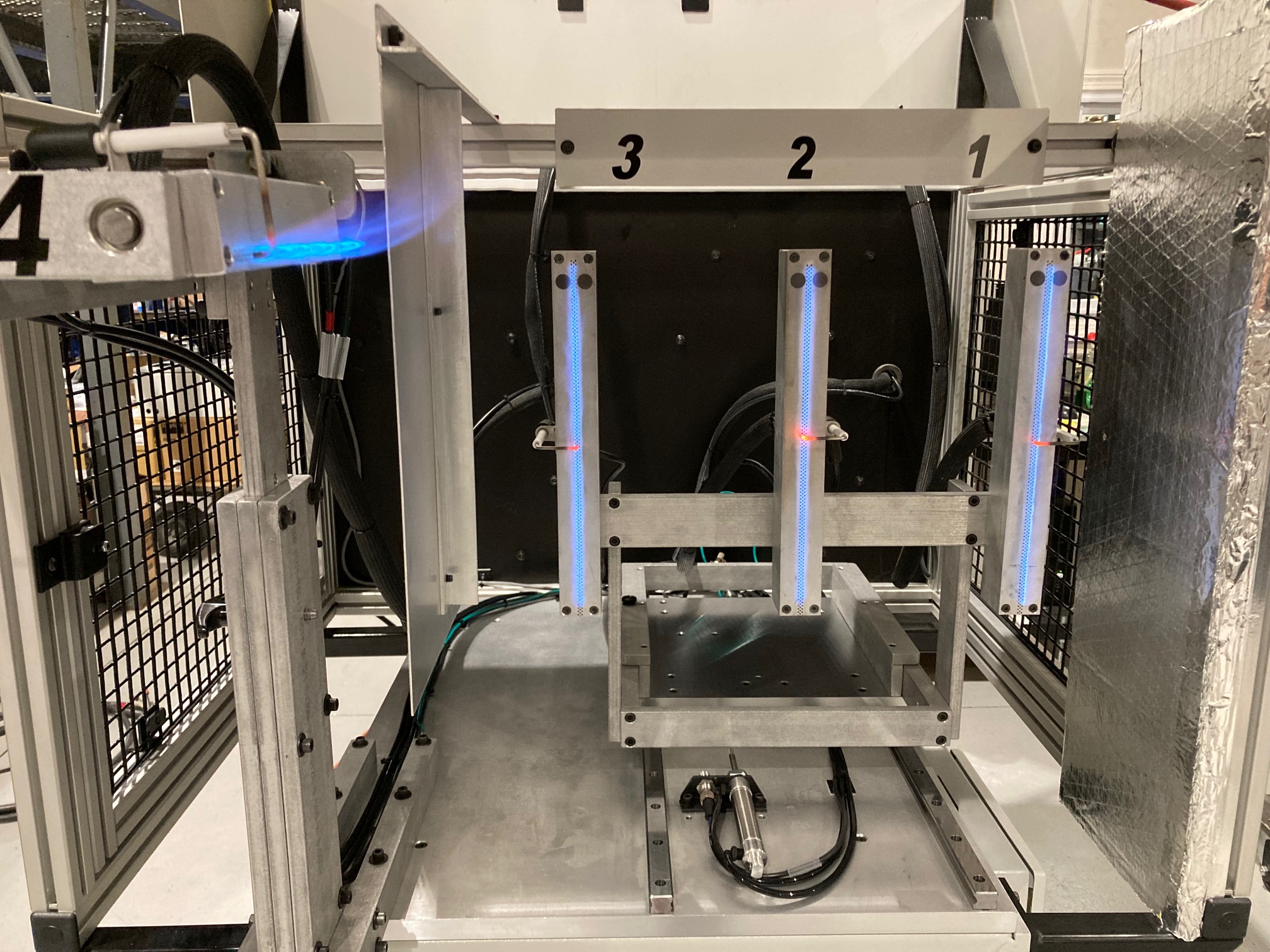

Fierosil System with One-Up Option

Pre-treatment Made Easy

Systematic Automation has been manufacturing and engineering automatic machinery with product handling for over 40 years. SA offers pre-engineered solutions for automatic pretreatment for your flat and cylindrical products. With the Fierosil system, you can expect consistent and reliable results every time. This eliminates the need for trial and error and ensures that your products are always properly prepared for printing. You can increase your production speed and meet tight deadlines without sacrificing quality. UV inks are ideal for high production.

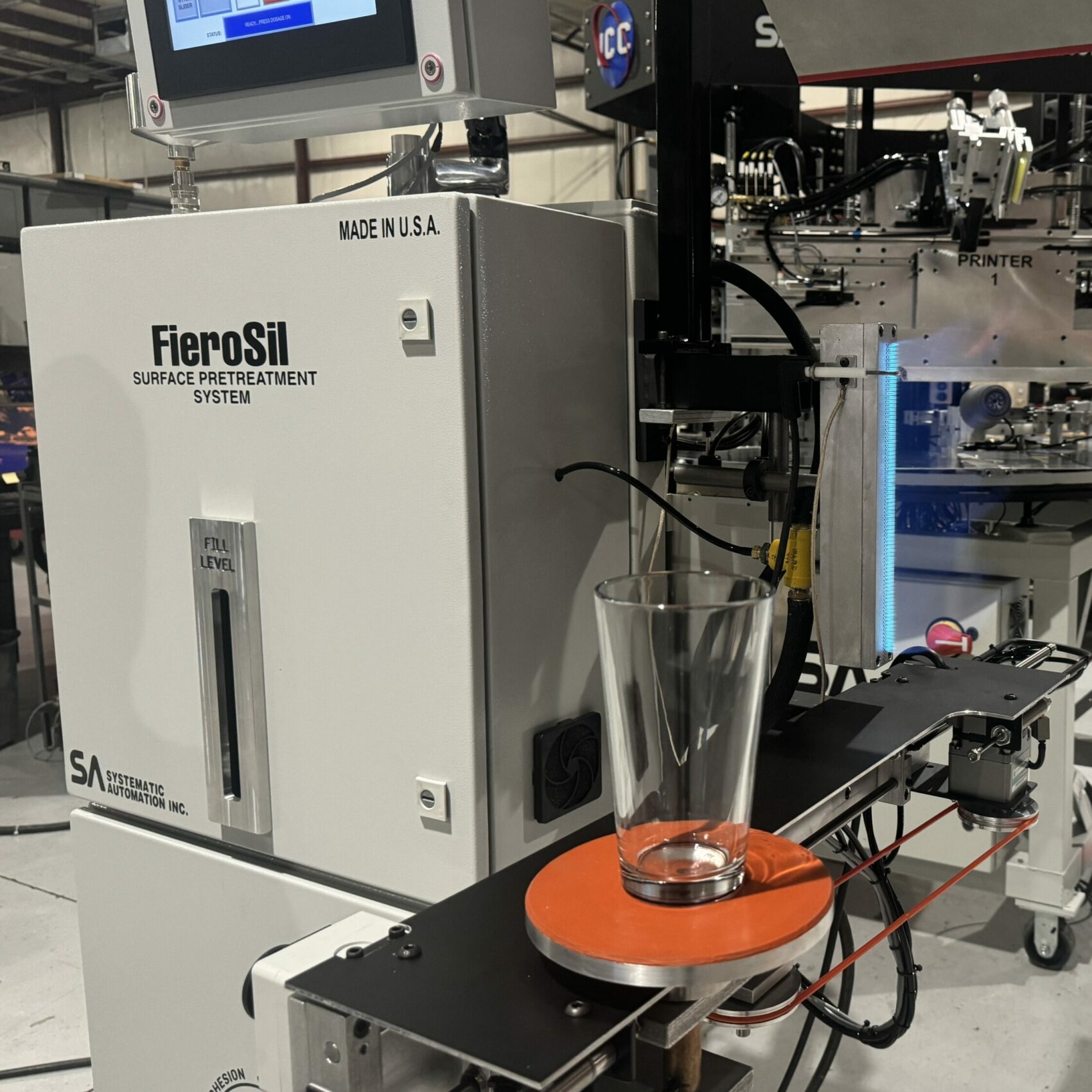

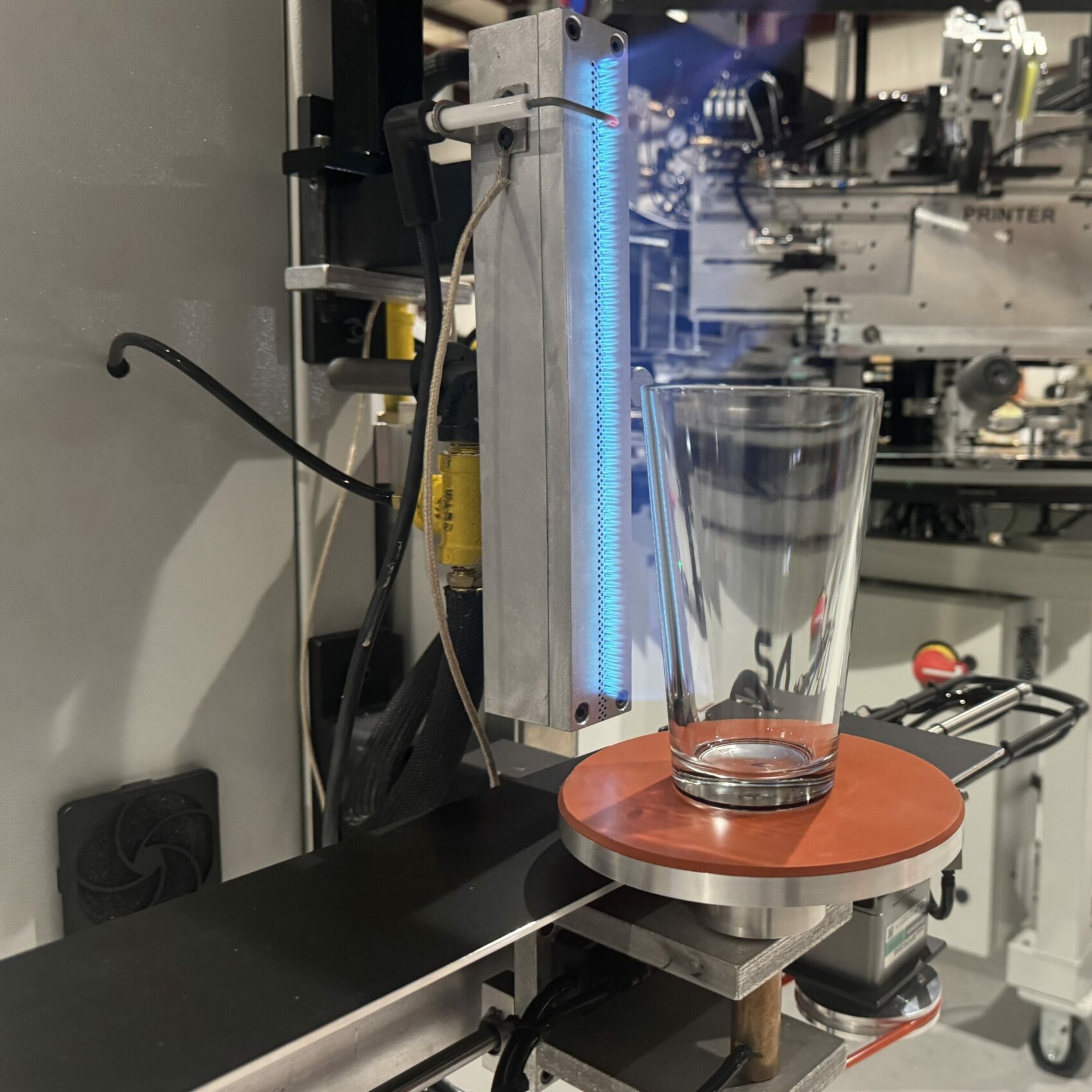

Systematic Automation offers a one-up option for your Fierosil System that you can see to your left. The universal vacuum platen used makes it ideal for treatment of different sizes and shapes of drinkware. The platen will rotate your product in front of the Fierosil flame and move back to the operator for pick up. The Flame 360 provides an eight station indexing station with vacuum platens designed for a variety of different drinkware. Both systems rotate the product 360 degrees while being exposed to the Fierosil for uniform coverage.

The modular design of the Fierosil makes it an ideal solution for your existing systems using flame treatment or on the SA line of Flame Treatment Systems. Speak today with a specialist on how we can bring the Fierosil to your shop floor.

Applications

How it works

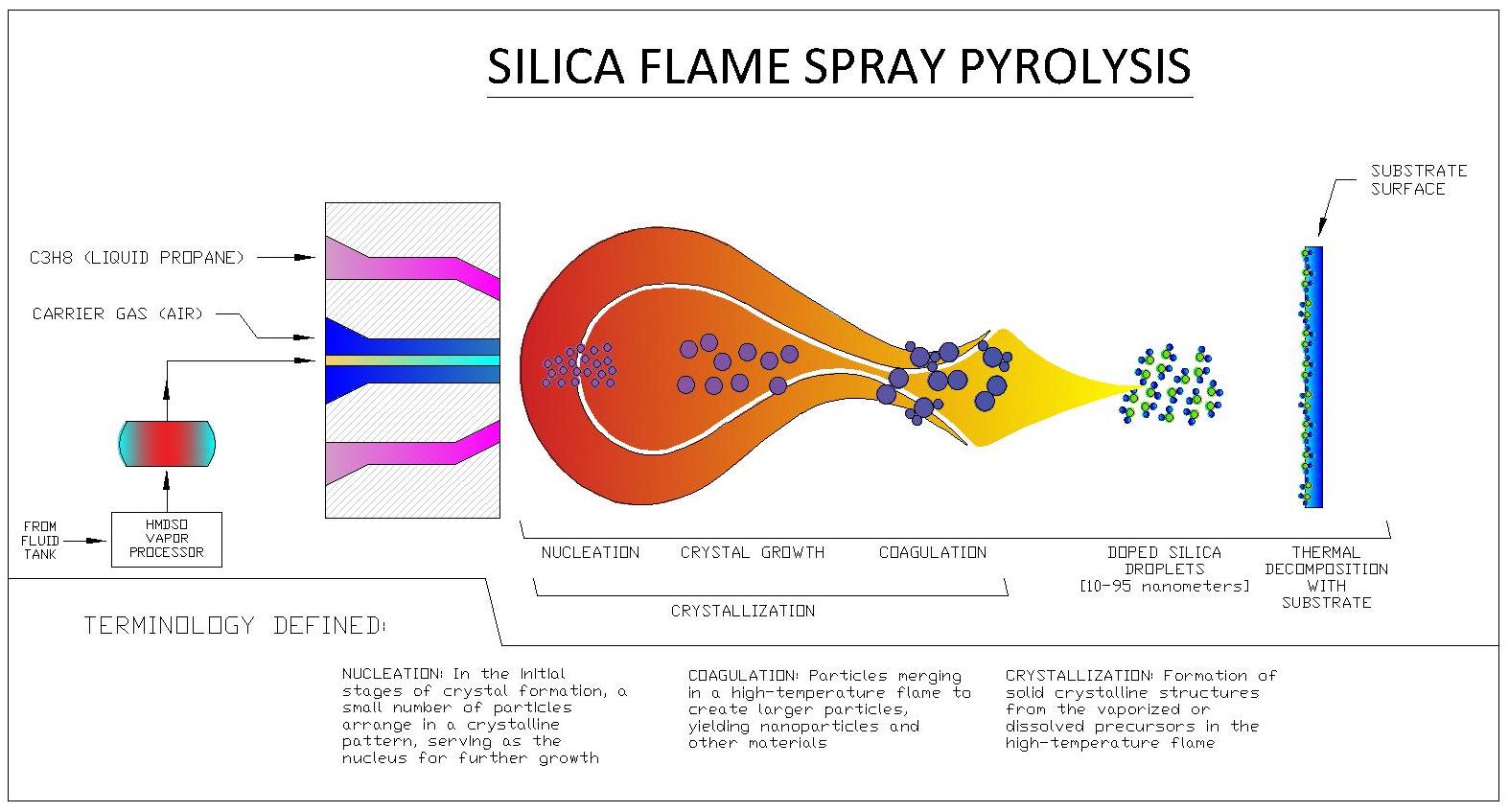

Fierosil relies on vapor deposition using purified Hexamethyldisiloxane as a consumable, which has been used on industrial applications since the 1950’s and is now widely used in the semiconductor industry. Systematic Automation has harnessed this technology and made it user friendly and affordable for the decorating industry.

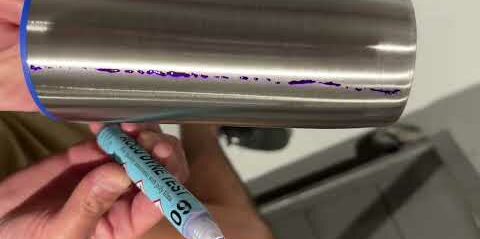

Ultra purified consumable precursor HMDSO is first vaporized and then precisely metered into a mixture of propane and air prior to combustion in the burner flame. There, the HMDSO converts into pure fumed silica. The super heated newly formed microscopic particles of silica (glass) is deposited onto the substrate by the force of the flame which is carrying it. As the silica particles fuse with the mating substrate they permanently raise the surface tension and increase the dyne level of the material. In effect it makes the surface more like fine sandpaper, but at such a microscopic level, even clear glass remains clear looking. However, if you drag your fingernail over the treated glass or other substrate, you can feel the higher coefficient of friction.

Surface preparation is a crucial step in the screen printing process. Without proper preparation, the ink may not adhere properly to the surface, resulting in smudging, bleeding, or peeling.

The Fierosil Solution is domestically made and packaged in SA headquarters and is available for immediate shipment.

Pre-Engineered and Custom Solutions Available

Systematic Automation performs all manufacturing processes at its headquarters in Farmington, CT. SA engineers have control over any custom features you would like on your flame treatment system. Proven solutions are available for material handling. Solutions can also be applied and tailored for a complete turnkey system for automatically pretreating your products. With over forty years of engineering & manufacturing, the chances are very good we can help you.

Have a Question?