Optical Registration System for Screen Printing

The Systematic Automation Automatic Optical Registration System can be used for your most intricate screen printing designs. It is made in USA using the highest quality industrial components. The optical sensor seeks light to dark, dark to light, and colors. It does this with extreme accuracy. You no longer have to rely on your operators to use pointers, fuzzy laser pointers, or unreliable mechanical means of registration.

Quick Changeover to different parts

Simply submit your products to our tooling department (the device comes with one set of tooling). Changeover from one part to the next is easy. Just change tooling end effectors and follow the simple step-by-step instructions supplied with the device. If your products are both straight walled and tapered, add the optional tilting sub plate.

How it works

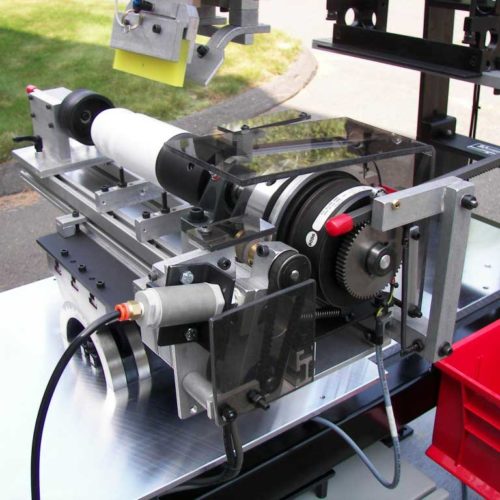

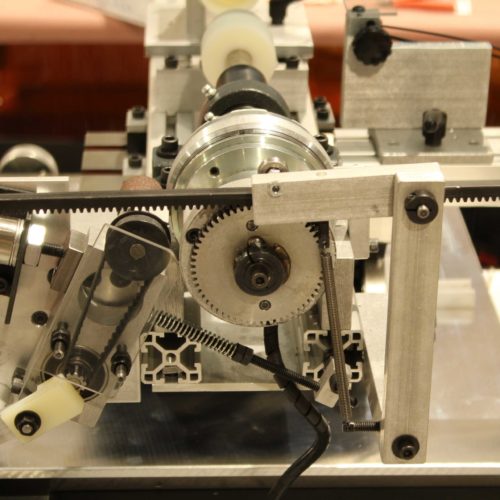

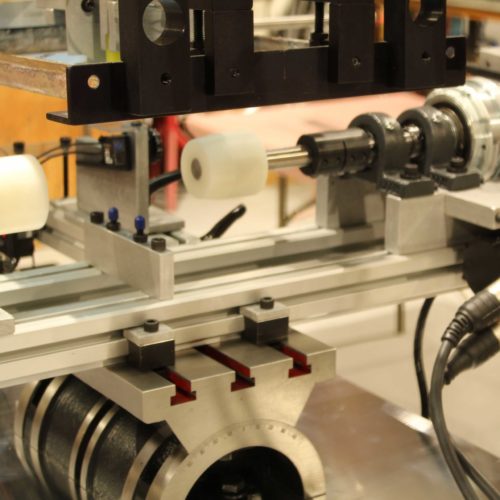

Place your product on the tooling and press cycle start. The device automatically grips your product. The servo drive rotates the part while the optical laser scanner seeks an existing mark on the product. This mark is sometimes an existing imprint (such as on Sigg bottles). If there is no existing imprint to register to, you then print your first imprint randomly on the product. The second color is applied in relation to the first color (or to an existing mark or label on the side of the product). Once the mark is sensed, the device disengages the servomotor and engages the rack and gear.

Gears are quick-change type. The gear is sized to the middle or mean average of your image. If your product is tapered, the quick-change gear is sized to match the diameter of your product at the center of your image location. Using friction to drive a part in multicolor screen printing is difficult with straight walled products and almost impossible with tapered products. This device gives you the control to produce a high quality imprint and minimize waste.

True RGB Optical Laser Registration System

The true RGB Optical Laser Registration System makes use of established, high tech optic technology to quickly and accurately register the product to be printed.

This unique system will see the registration point you determine and accurately return each part to that position for multicolor, mutliple pass printing. The extra small .157″(4mm) diameter beam spot permits detection of minute targets as small as .039 (1 mm) in diameter. This system will register any part or color with an accuracy of plus or minus .001″ (.025 mm). Simple, reliable set-up and operation are standard.

This option is available on any Systematic Automation screen printing machine. Contact us today to learn more.

Discover More Specialized Screen Printing Accessories and Add-Ons

Systematic Automation manufactures a variety of specialized tooling fixtures and accessories to adapt and expand the capabilities of your printer. We have designed tooling for many situations, so what might be a custom job somewhere else, at Systematic Automation is a standard option. View our complete line of screen printing accessories.