KEG Screen Printing Machine

- Machine tool quality and durability.

- Independent flood bar & squeegee height micro-adjustment.

- Universal screen mounting.

- Top quality linear ball bearings rated at over 300 million cycles.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

- Product Description

- Features

- Typical Applications

Product Description

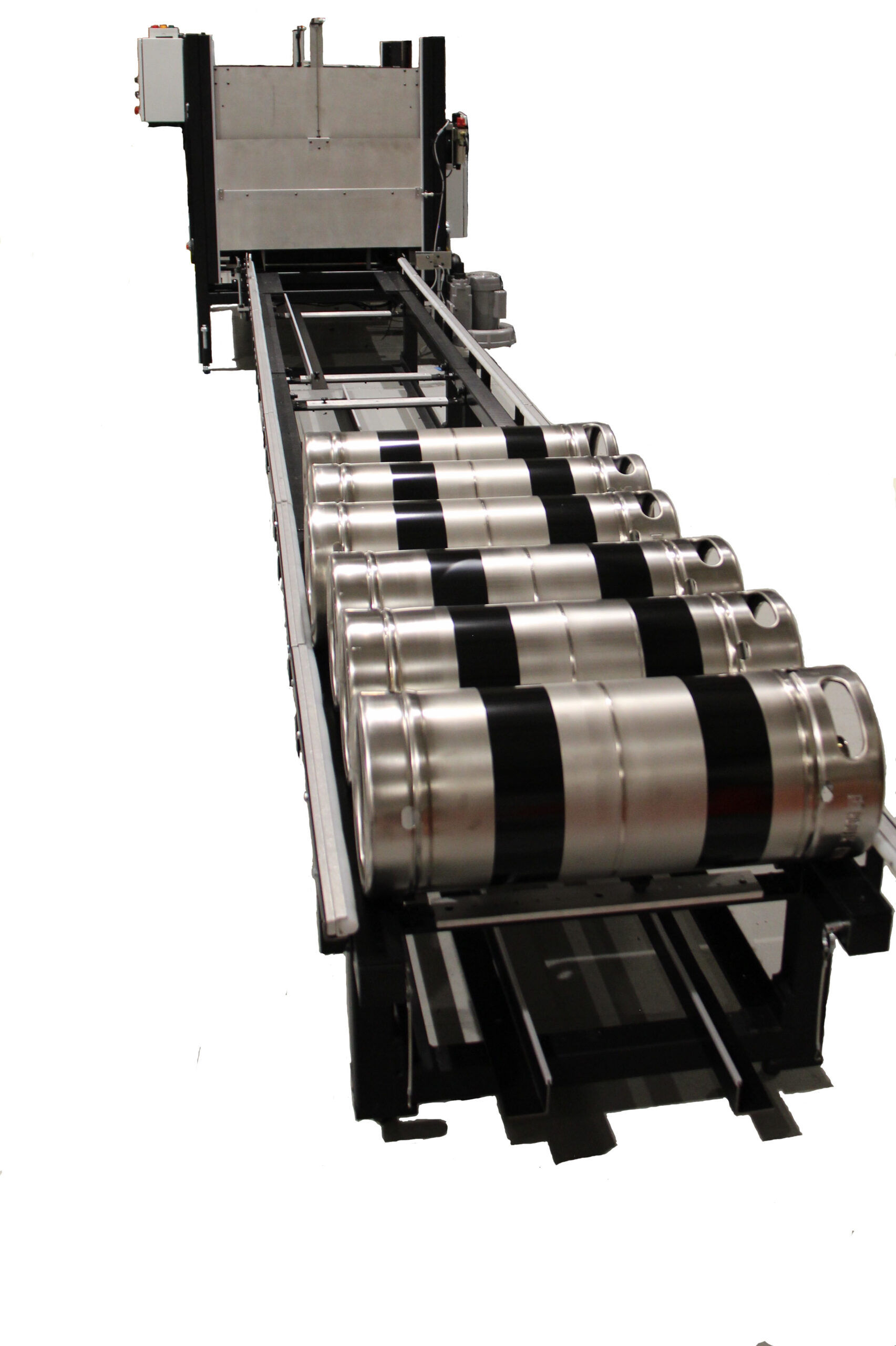

Print Your Kegs Quickly and Easily

English Data Sheet | Spanish Data Sheet

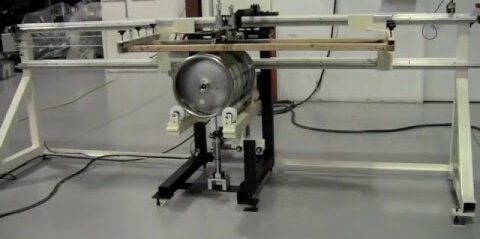

The KEG Screen Printer combines design simplicity, versatility and quality craftsmanship to create a system that will repeatedly get the job done. Printing your kegs has never been easier. UV curing system for your kegs are available, refer to our Model UVSP if you are using UV inks.

The KEG Screen Printer can print kegs up to 20″ (508 mm) in diameter as well as print up to four colors at the same time on one screen using our multi-color printing attachment. The print cycle of the machine is initiated by a foot pedal and can be operated in single or auto cycle mode depending on whether you are making adjustments or running full speed production.

The machine comes with three different sizes of tooling, which make it ideal for screen printing kegs of different capacities (standard: 1.2KEG, 1.4KEG, 1.6KEG – other sizes available). You even have the option to print beer growlers & pint glasses, making this a one stop shop for printing the products in your industry. The modular design of the Keg Printer allows you to place the tooling on the printer with minimal adjustments between different sizes of kegs.

Built in the USA with the highest standards of materials and workmanship, exclusively for the brewing industry. The KEG Screen Printer sets new standards for precision and productivity.

Features

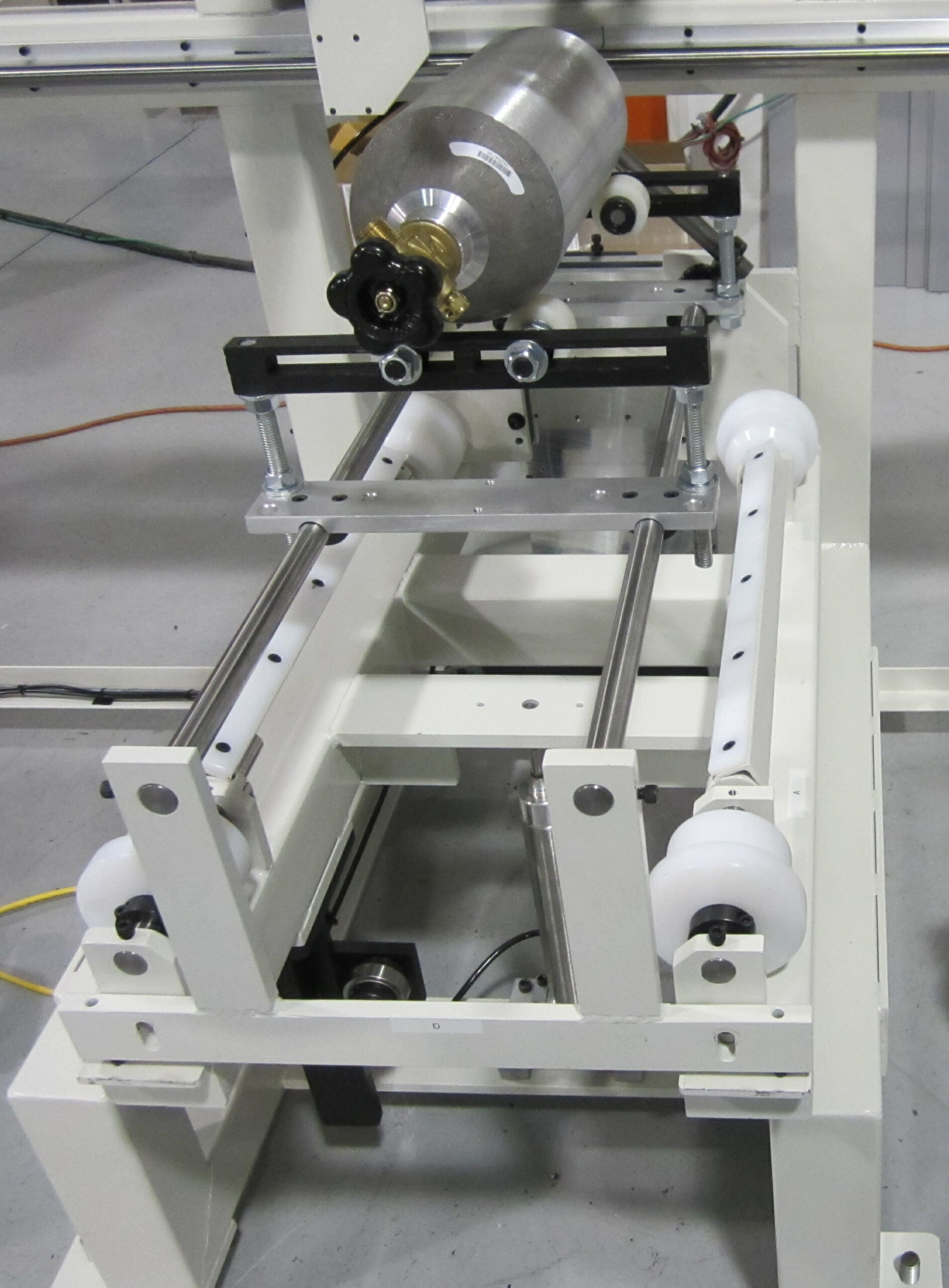

Engineering Features

- 100% made in USA.

- Machine tool quality and durability.

- Independent flood bar & squeegee height micro-adjustment.

- Universal screen mounting.

- Quick release squeegee holder and flood bar assembly.

- Stainless steel air cylinders.

- Hardened, ground, and polished shafts with linear ball bearings rated at over 300 million cycles.

- Flood bar rises and falls alternately with squeegee.

- Smooth, quiet operation.

Standard Features

- Includes all necessary tooling for printing 3 sizes of basic style beer kegs. (Standard: 1.2KEG, 1.4KEG, 1.6KEG – other sizes available)

- Emergency stop buttons.

- Harmonic lift with 8″ (203 mm) movement upward to screen.

- Foot pedal cycle start.

- Heavy-duty welded steel base.

- Squeegee holder.

- Flood bar.

- Independent squeegee/flood bar height adjustment.

Options

- Dual print head for precise squeegee pressure for images 16” (406 mm) or wider.

- 5 digit stroke counter.

- Adjustable squeegee pressure with gauge and regulator.

- Multicolor printing attachment.

- Beer growler & pint glass tooling.

- Automatic Ink Dispenser.

- Screen Tension Meter.

Typical Applications

- Stainless Steel Kegs

- Finn Kegs

- RSR Kegs

- Optikegs

- Wine Kegs

- Growlers

- CO2 tanks

![kegprinter[1] copy keg printer, keg, screen printing](https://systauto.com/wp-content/uploads/2017/01/kegprinter1-copy-scaled.jpg)