Flame 360 | Flame Treatment Machine

- Ideal for cups, glassware, bottles and more.

- Part flexibility for cylindrical and irregular shaped items.

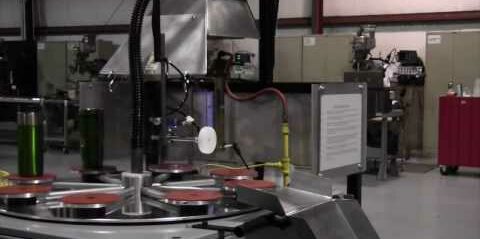

- Geneva indexer provides harmonic dial motion.

- Entire print area is rotated 360 degrees through the flame.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

- Product Description

- Features

- Typical Applications

Product Description

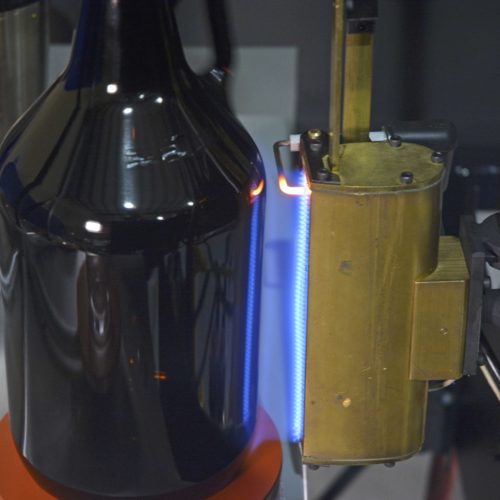

The Flame 360 (U.S. Patent# 6,397,491 B1) is a versatile workhorse of flame treatment systems. The system is designed for quick pretreatment, durability and continuous use. Burners are available in the following sizes: 6″ (153mm), 10″ (254mm) and 12″ (305mm). Larger sizes are available upon request.The height of the flame can be adjusted through a magnetic metal strip that rests on your burner. Fierosil is available for optimal ink adhesion.

Features

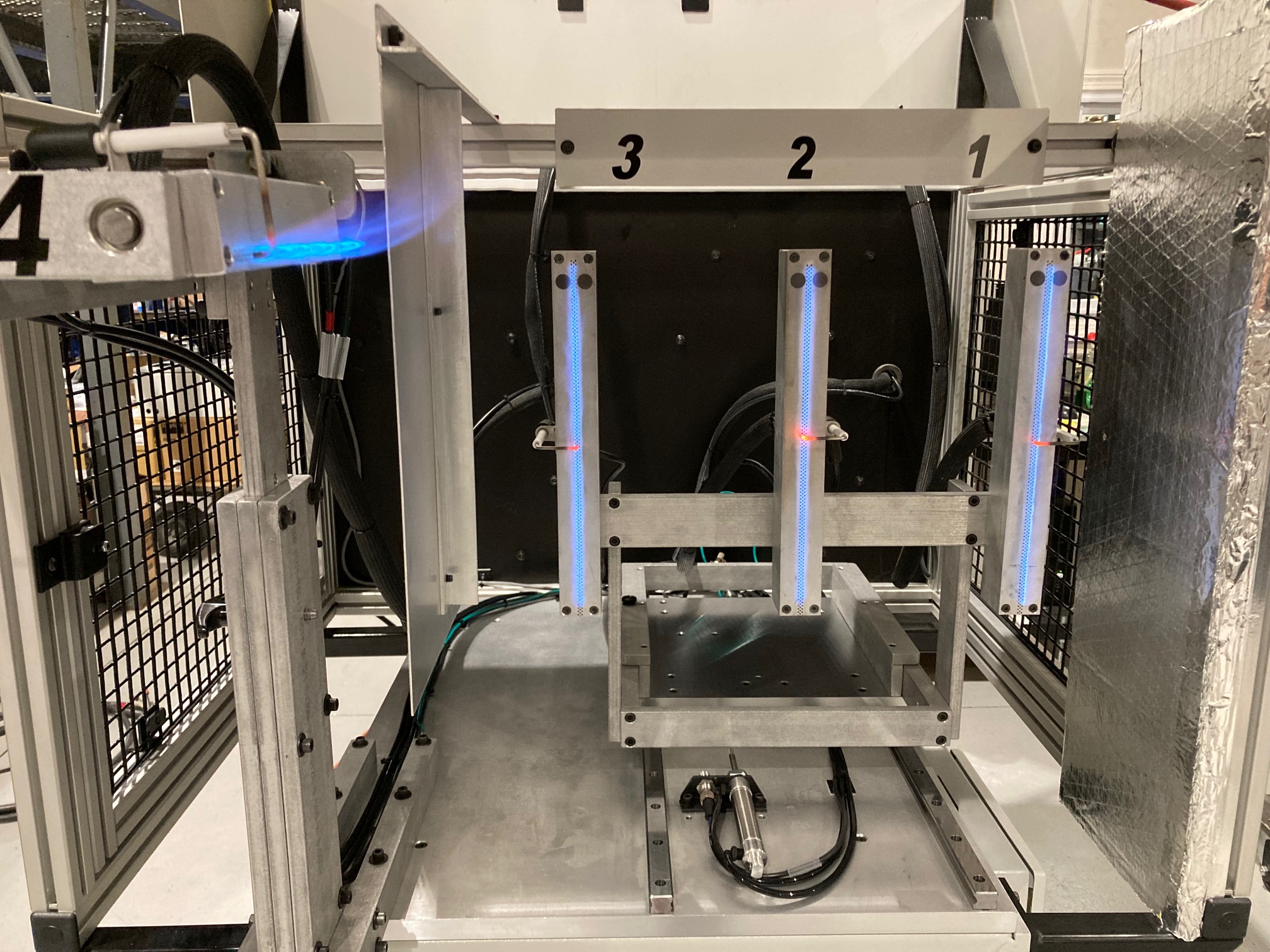

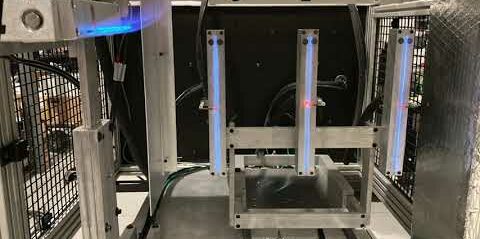

- Height and angular adjustment for SA burner.

- Universal vacuum plates securely hold most cylindrical products without the need for special holding nests. Dedicated tooling made for odd shaped products.

- Uses an all mechanical Geneva indexer with a brilliantly simple overload clutch. The Geneva indexer provides harmonic (smooth acceleration and deceleration) dial motion.

- Entire print area is rotated 360 degrees through the flame to maximize adhesion. Uniformity of treatment is guaranteed.

Features

Engineering Features

- Part flexibility for cylindrical and irregular shaped items. Sizes from ball point pen barrels to gallon containers.

- Height and angular adjustment for burner.

- Overload clutch.

- Machine control technique entirely eliminates the problem of electrical component obsolescence.

- Geneva indexer provides harmonic (smooth acceleration and deceleration) dial motion.

- Entire print area is rotated 360 degrees through the flame to maximize adhesion. Uniformity of treatment is guaranteed.

- Rotating through the flame allows for the fastest cycling time while ensuring thorough, consistent treating.

- Once parts are loaded, no rollers, belts, or escapements adjust. Changeover from one part to the next can’t get any easier.

- Whether promoting adhesion for UV inks, coatings, or adhesives, the flame treatment system allows adjustment of indexing and rotation speed as well as flame height.

- Compact design.

- Affordable price.

Standard Features

- Incorporates an 8 station Geneva Drive

- Automatic unload – Consists of mechanical eject of parts

- Number of stations – 8

- Adjustable flame burner – 12″ (304 mm)

- Platen diameter – 6″ (152 mm)

- Rotary dial diameter – 32″ (813 mm)

- Input power – 115 VAC

- Fuel – Natural Gas or Propane (please specify at time of order), tank not included

- Exhaust hood

- Compressed air (80 psi) required for automatic unloader

- Heavy duty locking casters

Typical Applications

- Mugs

- Pint Glasses

- Growlers

- Glass Bottles

- Glassware

- Plastic Bottles

- Drinkware