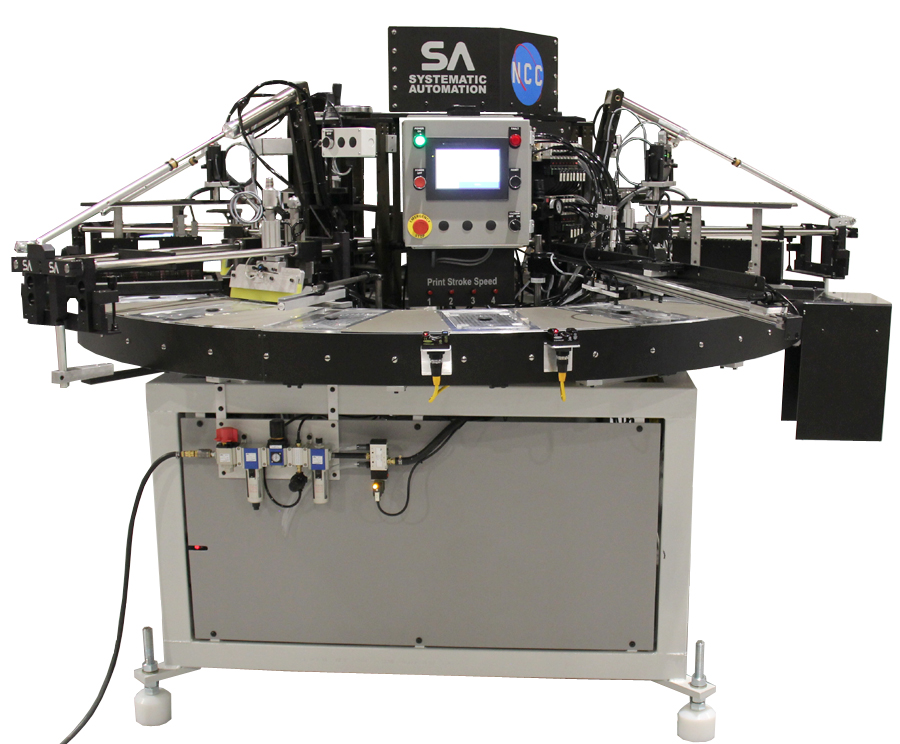

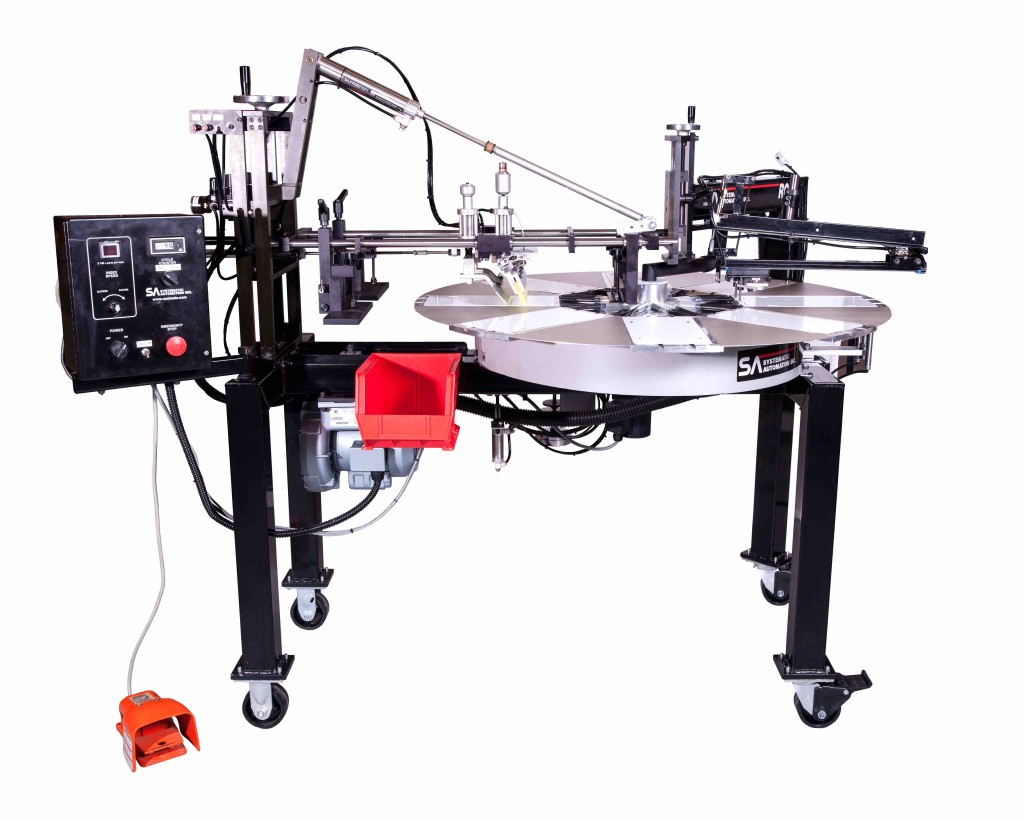

NCC Screen Printing Machine

- Highest quality servo motor drive and reducer are used.

- Approximately 3,600 prints per hour (depending on product).

- Modular design permits easy modification and integration.

- Electronic positioning of extreme accuracy +/-.001″(.025 mm) at all stations.

- Hollow Ring™ dial to servo drive coupling is overload crash protected.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

- Product Description

- Features

- Pretreatment

Product Description

Achieve Up To 3,600 Multi-Color Prints Per Hour

English Data Sheet | Spanish Data Sheet

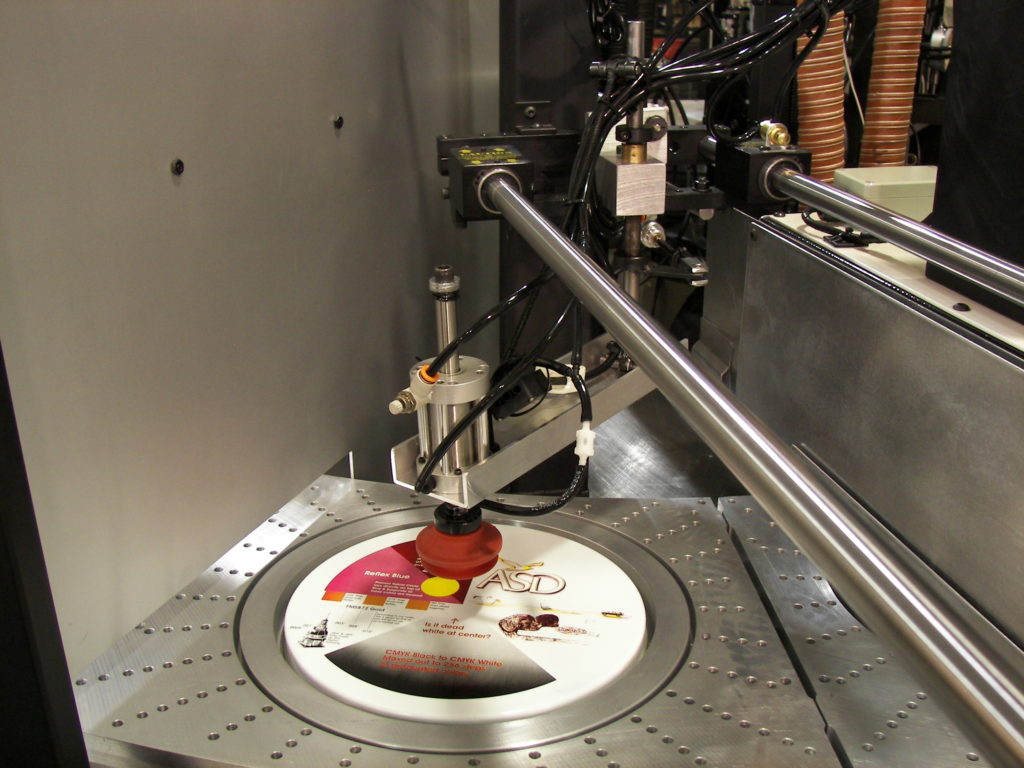

The Model NCC Screen Printer (US Patent # 5,784,932) is a great innovation which delivers superior performance. The NCC is designed for unrivaled speed and exceptional productivity. Speeds variable to 3,600 cycles per hour (depending on article) are easily achieved.

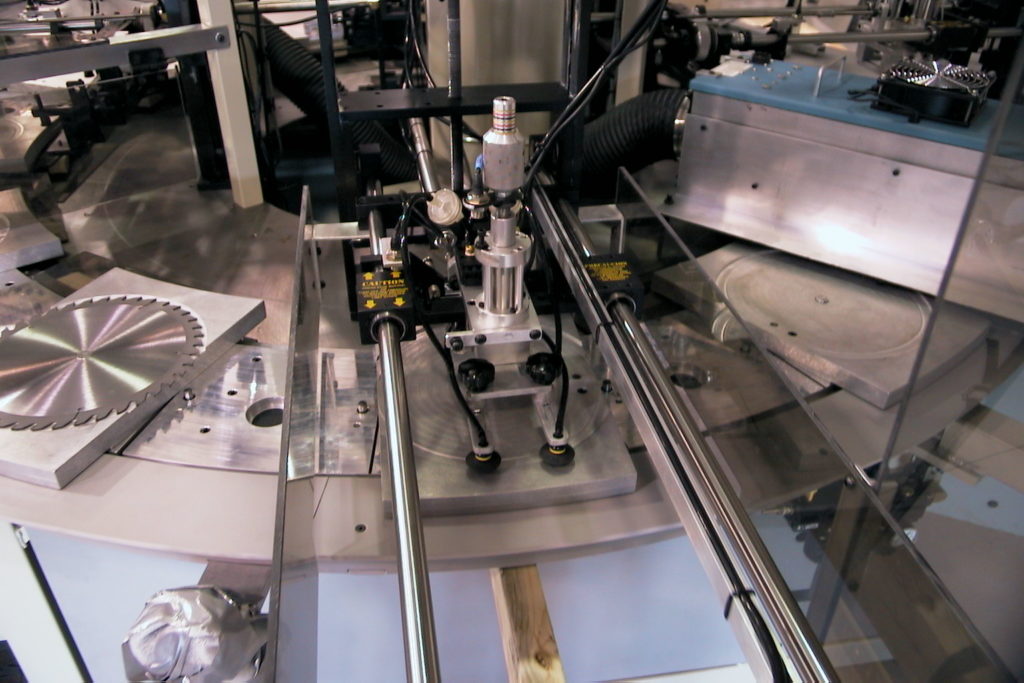

The NCC features a patented, servo motor drive with zero backlash. This combined with precision machining assures high accuracy. The table position will repeat within +/- .001″ (.025mm) and will not degrade with use. This allows the most impressive four color process and multi-color images to be produced. At the heart of the machine is the Systematic Automation Hollow Ring high speed, super precision indexer. A patented high speed UV shutter escapement delivers precise UV curing exposure.

Features

Engineering Features

- Reliable, simple design.

- Smooth high speed operation.

- Highest quality servo motor drive and reducer are used.

- Modular design permits easy modification and integration.

- Electronic positioning of extreme accuracy +/-.001″(.025 mm) at all stations, regardless of index table diameter.

- Hollow Ring™ dial to servo drive coupling is overload crash protected. No damage to machine or drive if rotation is obstructed.

- Infinitely adjustable squeegee stroke speed and flood stroke speed.

- Variable squeegee pressure with gauge.

- Adjustable squeegee skew angle.

- Bottom of screen to top of part “off contact”(Z axis) is adjustable via a hand wheel.

- Printer carriage lifts for access to the bottom of the screen frame and access to the squeegee holder.

- Screen pivots on a precision hinge, away from the print head for access to the squeegee and flood bar, and inside of screen from with no loss of registration.

- 100% CAD designed. All parts CNC machined in-house directly from CAD which ensures replacement part consistency.

- All pneumatic exhaust ports are piped to a common tube for venting out of the production room.

- Solid, all steel base, aircraft quality Tig welds throughout.

- Bearings rated at well over 400 million cycles.

- Indexing table movement and number of stations is programmable via the operator interface.

- Stainless steel shafts, nickel plating, and anodizing are used throughout to resist corrosion.

Standard Features

- Two 12″ (300mm) stroke screen printers with X-Y and angular micro adjustment for screen frames (up to 6 colors maximum).

- Pre-registration pins on screen frame holder.

- Squeegee holders in choice of two different widths and lengths of squeegee materials; 3/16 x 1″ (4 x 25mm) or 3/8 x 2″ (9 x 50mm).

- Part holding vacuum is delivered throughout the entire Hollow Ring Dial.

- Heavy duty vibration absorbing rubber machine leveling pads.

Options

- Modular automatic take-off device.

- Three precision dial indicators mounted on X, Y, and angular micro adjustable table.

- Off contact precision dial indicator.

- Adjustable squeegee angle.

- Product present detect system.

- Pre-registration system for screen exposure.

- Dual print head for precise squeegee pressure for images 16” (41 cm) or wider.

- Vacuum table. Anodized top surface available.

- Anti-static device.

- Pre-print product cleaning tacky roller.

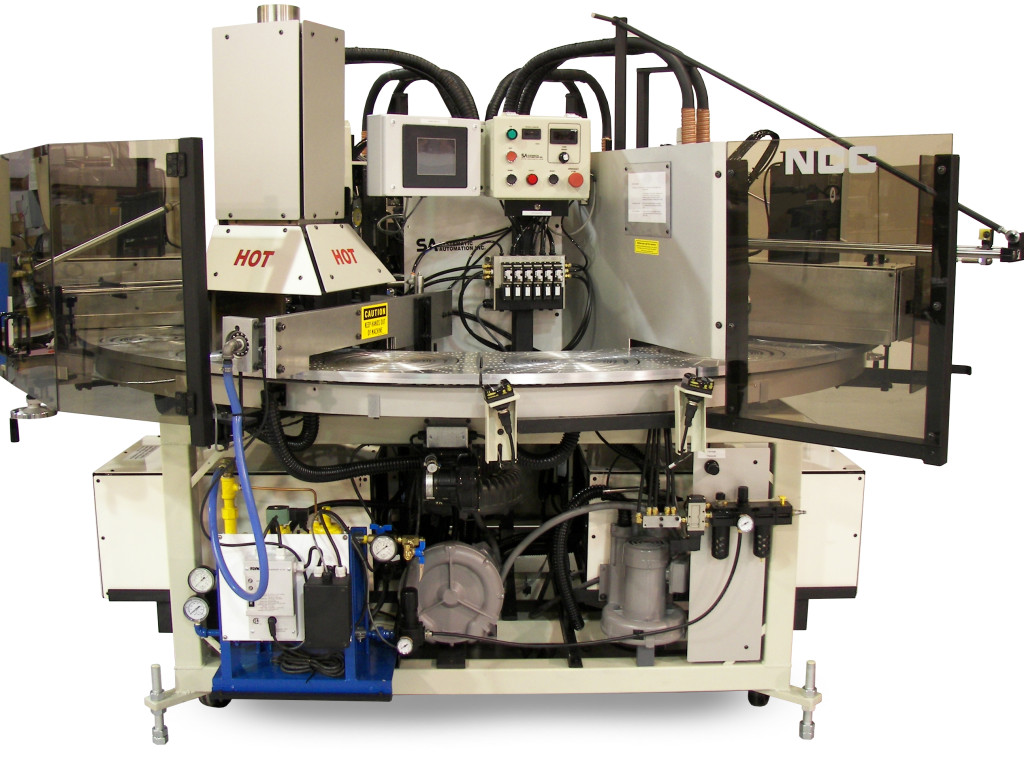

- Surface treatment flame, corona or pyrosil.

Pretreatment

Your product surface may require pretreatment to promote ink adhesion. Products ordered in bulk may have oil contaminants or other residue as well as having poor surface tension, which can be remedied by flame pretreatment. Pretreatment integration is done by installing a burner on your machine that will provide flame to your entire surface area. If your product is cylindrical, it will spin 360 degrees, parallel with the burner and if it is flat, the flame system will move to cover your product area. Burners are made in house and to size. Pretreatment is done prior to printing your product.