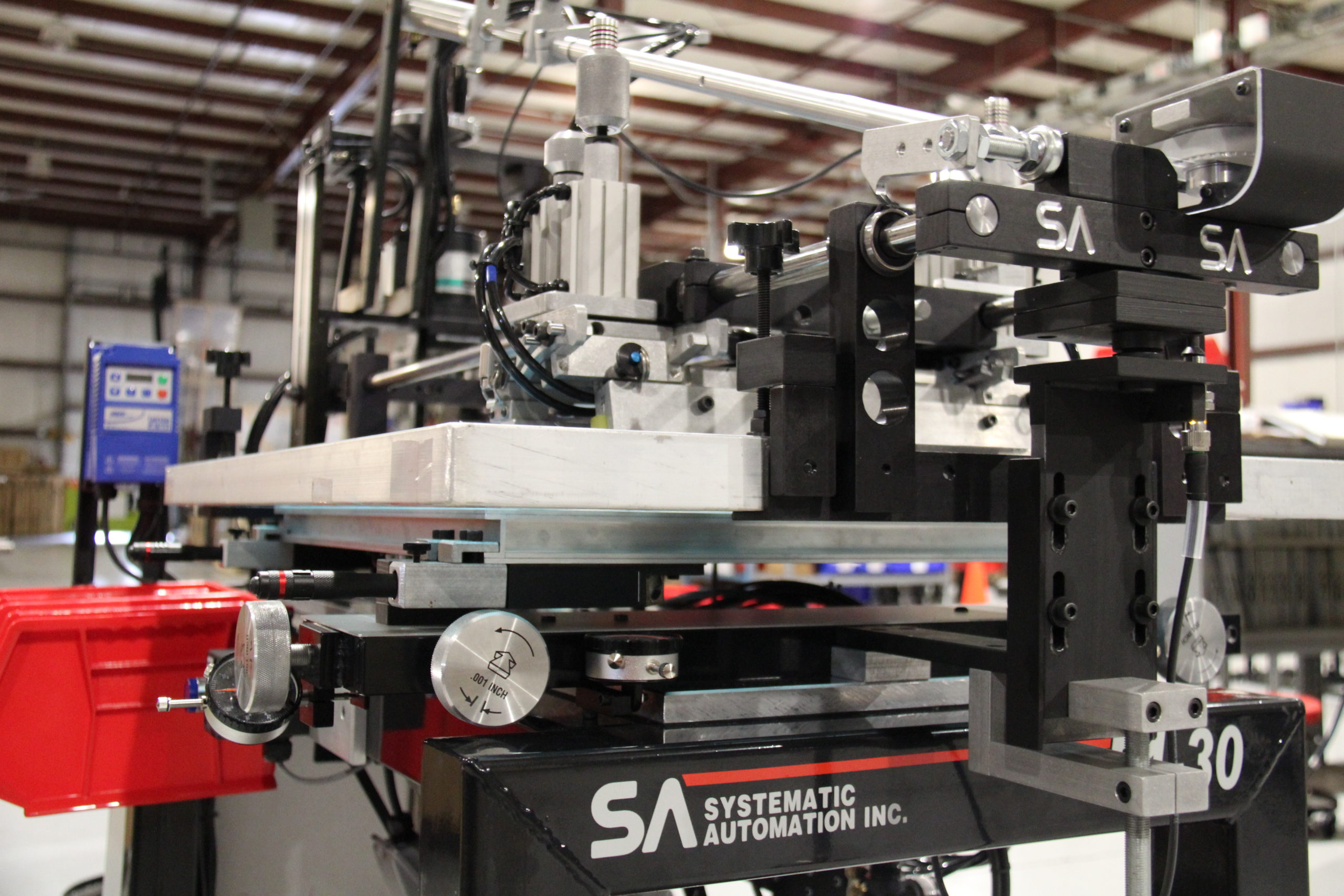

F1 Screen Printing Machine

- Approximately 3,600 prints per hour (depending on product).

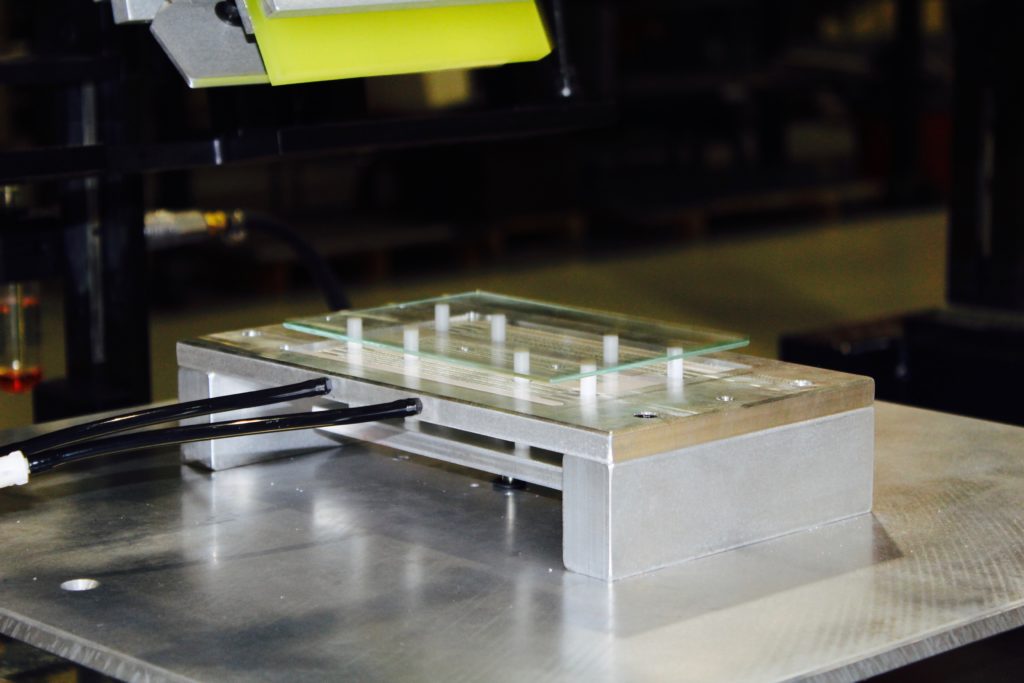

- Aluminum tooling plate base ground flat within +/- .001” (.025 mm).

- Capability to print flat & cylindrical products.

- Pneumatic system cannot overload, burn out, or become obsolete.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

- Product Description

- Features

- Typical Applications

Product Description

The Right Solution For Every Industry

English Data Sheet | Spanish Data Sheet | Manual

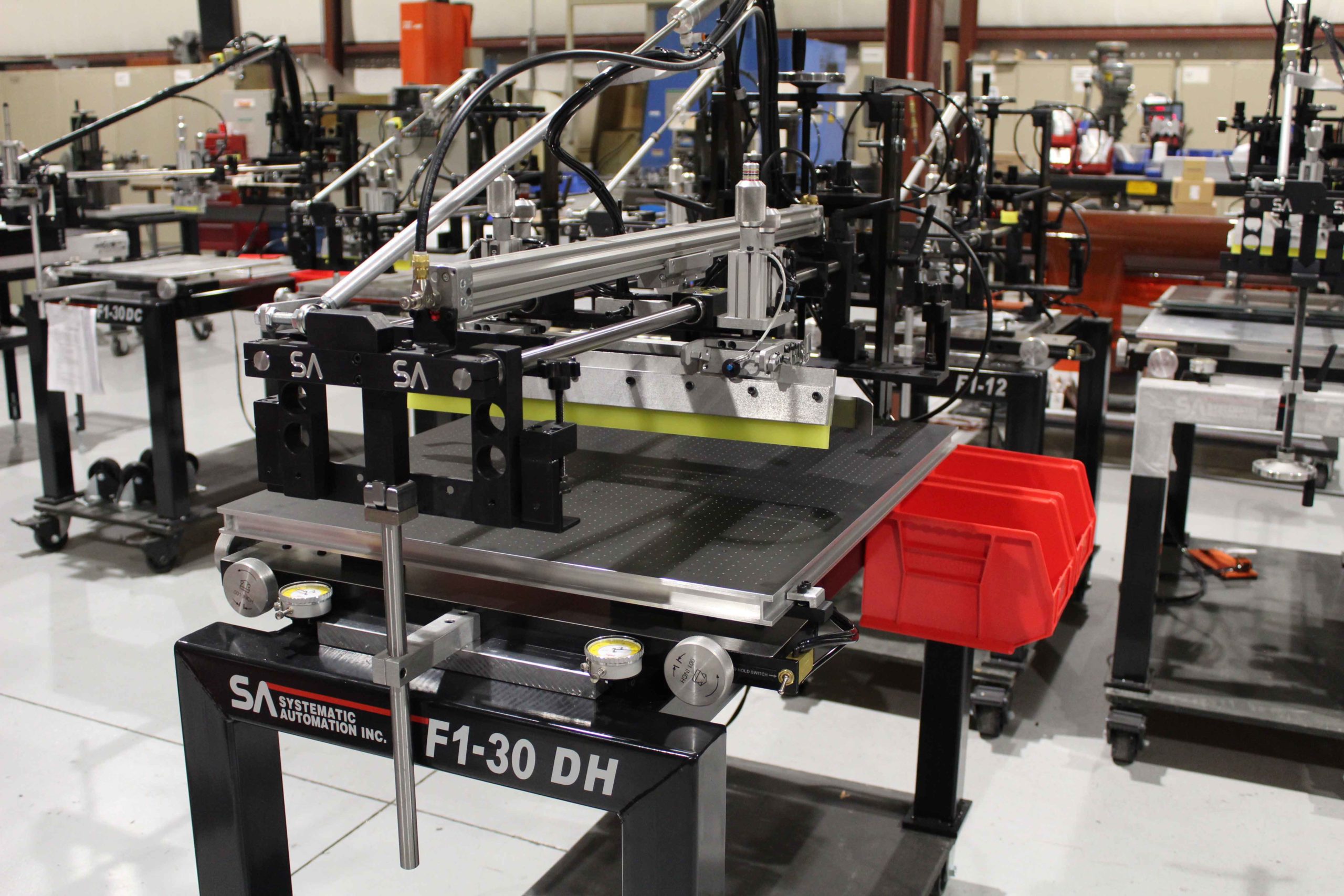

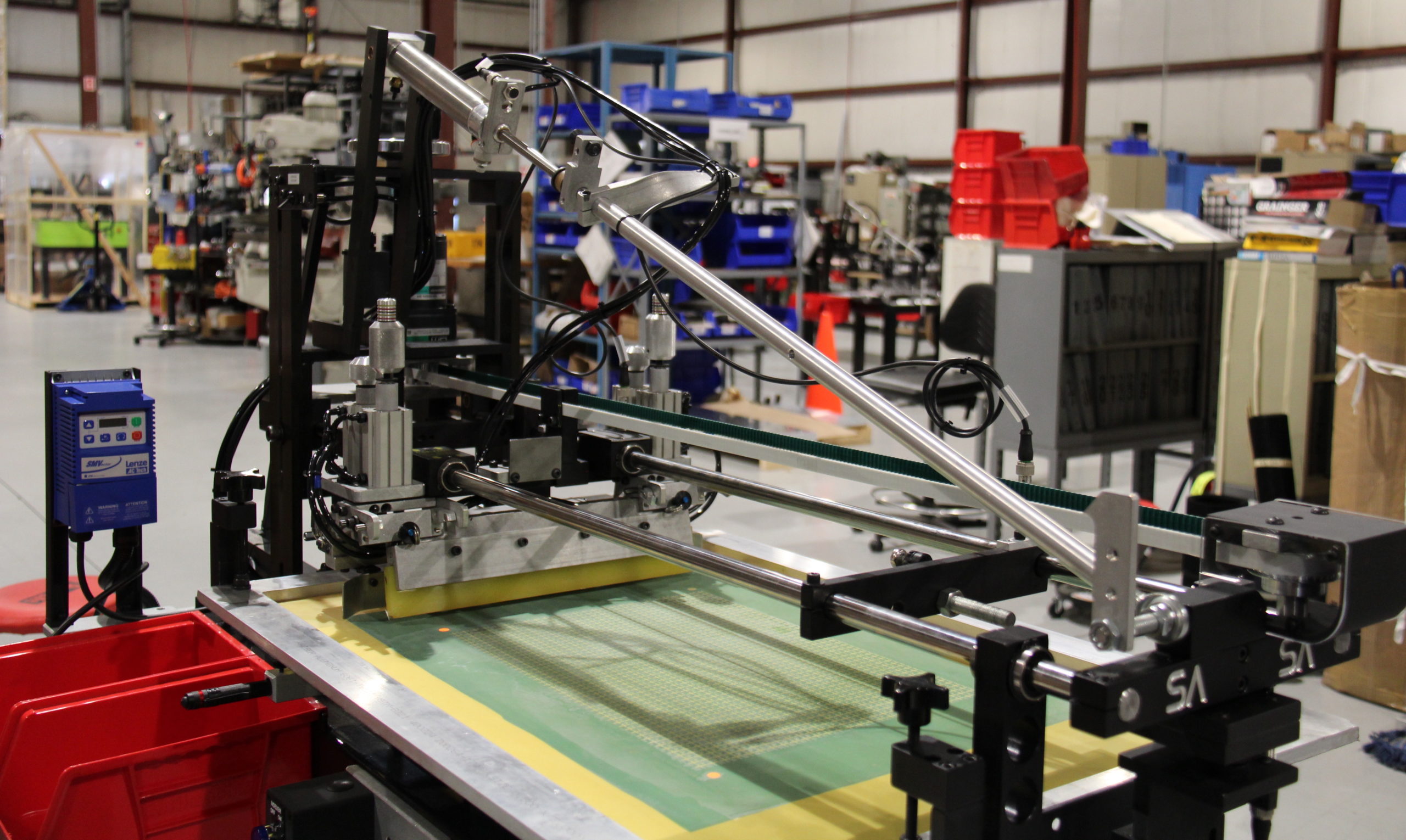

The Systematic Automation Model F1 Semi-Automatic machines are the proven solutions of the industry, combining high quality manufacturing standards & user friendly design for years of dependable, precision performance. Extremely simple and reliable, these versatile printers are for a limitless range of screen printable products, regardless of shape or material. You also have the option of changing over from printing flat to cylindrical products in minutes. Engineered and manufactured entirely in the USA, the F1 printers provide the innovation and craftsmanship needed to meet the most exacting production requirements

Designed to grow your business, Systematic Automation offers literally hundreds of attachment combinations to accommodate future applications. The addition of modular components easily upgrade the F1 to fulfill increased production and customization demands. Click here for a list of attachments that may be used on your machine.Tooling can be made specific to your product and feature customizations for improving your printing process.

The Model F1 can print cylindrical products (inquire within).The Model F1-DC is dedicated for cylindrical. The Model F1 offers versatility, unparalleled precision and customization for your process.SA is available to you for immediate assistance when troubleshooting or if you need assistance getting started with screen printing.

Whether you have just begun printing or are a seasoned veteran, the Model F1 will offer simplicity and options for you on improving your set up time, clean up, imaging and much more.Contact us today to get started. With over 40 years of experience, the chances are very good we can improve your screen printing process.

Features

Engineering Features

- 100% manufactured in USA.

- Capability to print flat & cylindrical products.

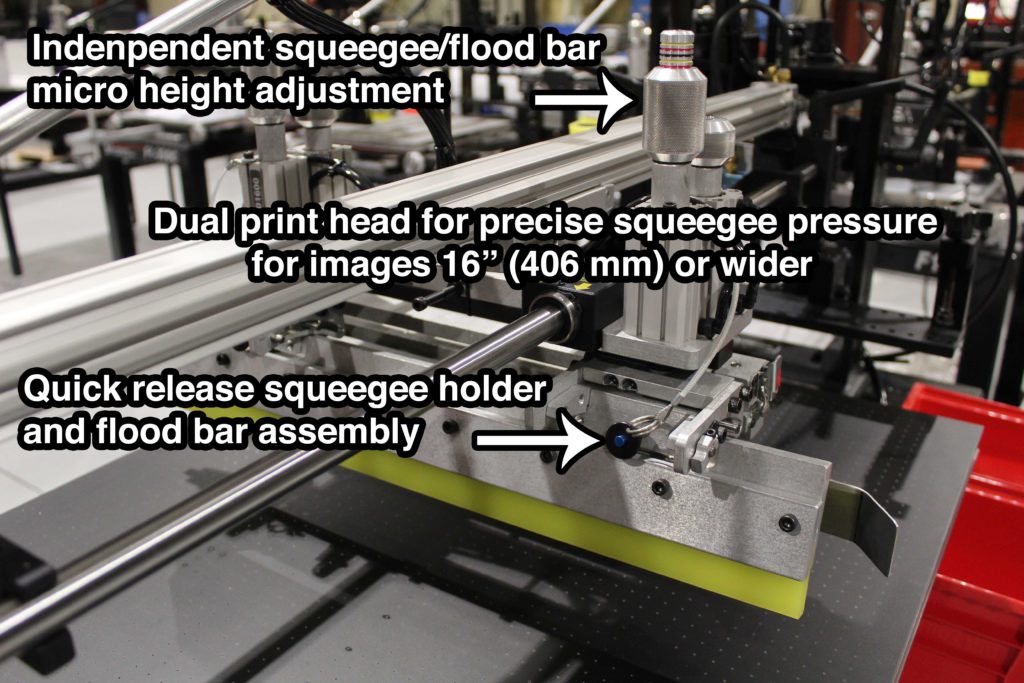

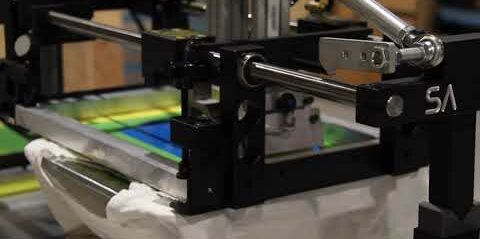

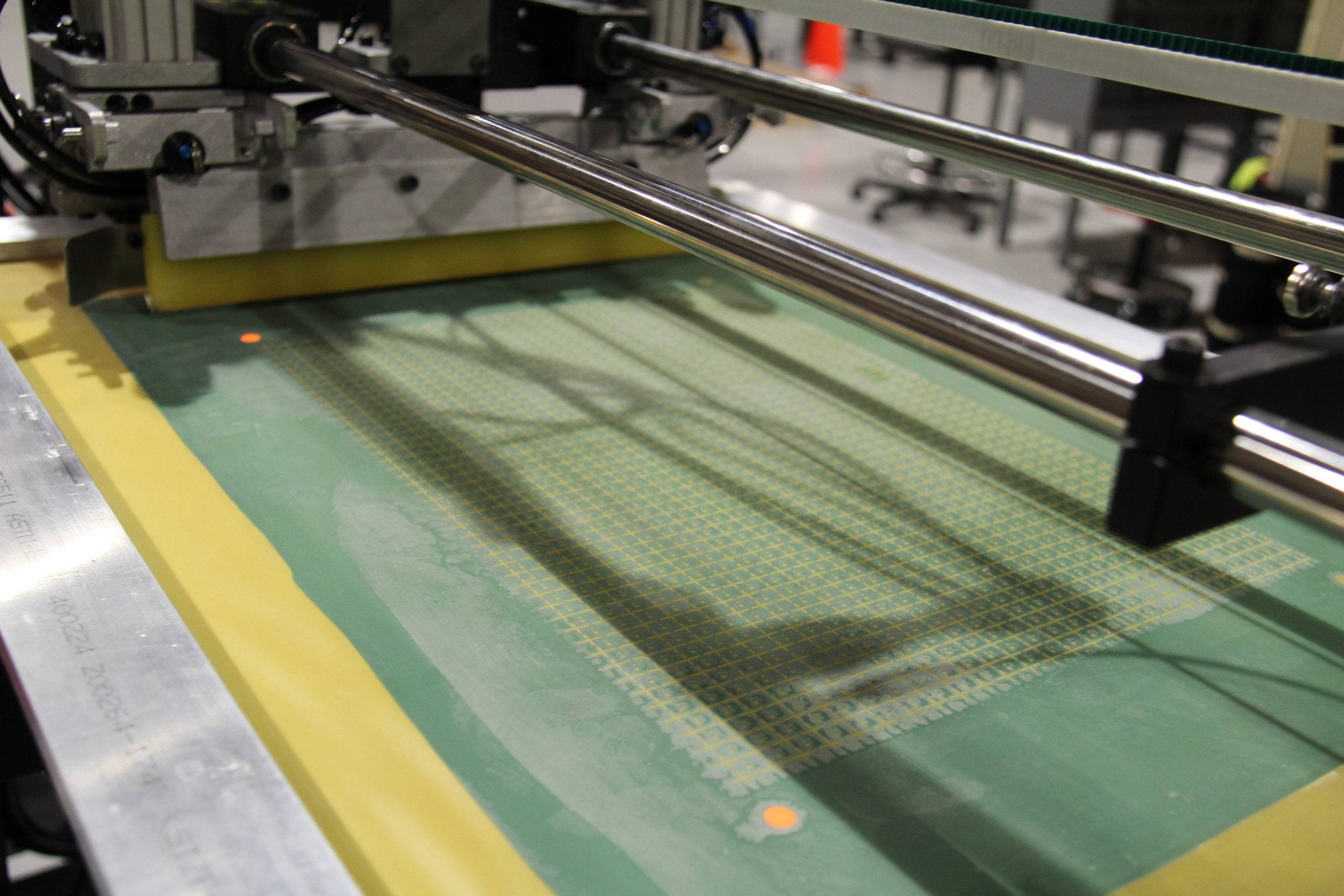

- Independent flood bar & squeegee speed/height adjustment.

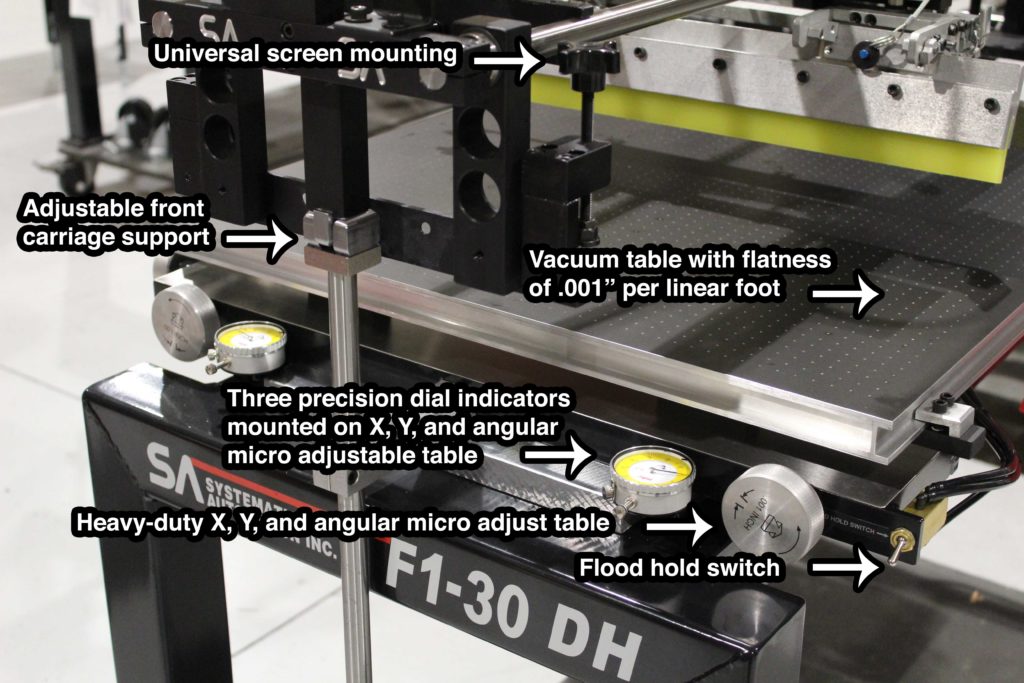

- Universal screen mounting.

- Hinged rear screen frame holder to provide quick access to screen, squeegee and flood bar without losing registration.

- Quick release squeegee holder and flood bar assembly.

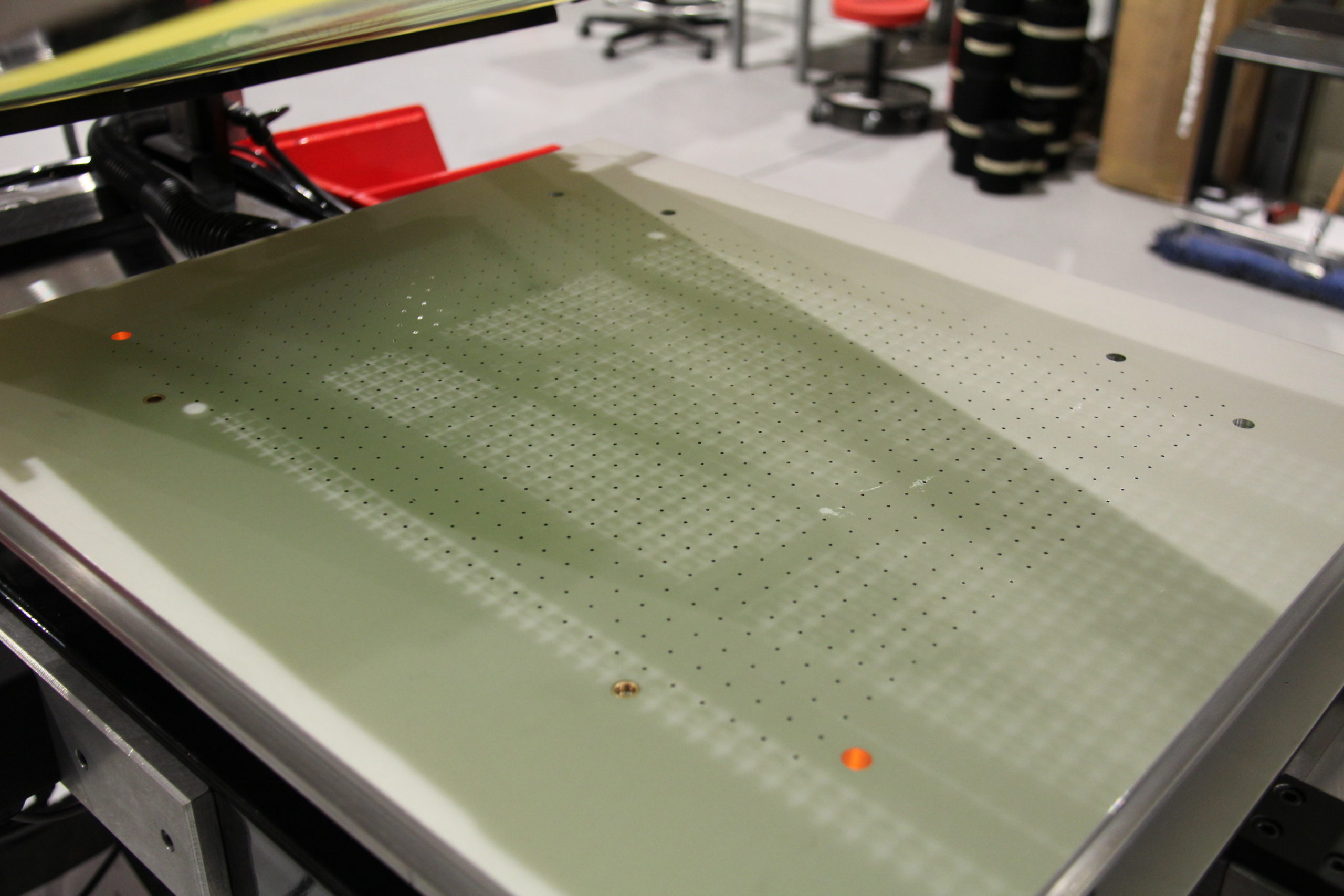

- Aluminum tooling plate base ground flat within +/- .001” (.025 mm).

- Micro-adjust knobs located on X,Y location of tooling plate.

- Smooth, quiet operation.

- 100% air operation.

- Pneumatic system cannot overload, burn out, or become obsolete.

- Machine tool quality and durability.

- Stainless steel air cylinders.

- Hardened, ground, and polished shafts with linear ball bearings rated at over 300 million cycles.

- Carriage closes with minimal force for operator safety.

Standard Features

- Variable flood bar speed.

- Adjustable print stroke length.

- Variable carriage down speed.

- Adjustable squeegee pressure with gauge and regulator.

- Foot pedal cycle start.

- Adjustable screen lift height.

- Print/flood cycle – machine “waits” in flood position.

- Air shut-off switch.

- Heavy-duty X, Y, and angular micro adjust table.

- Heavy-duty welded steel base with casters and tote bins.

- Squeegee holder.

- Independent squeegee/flood bar micro height adjustment.

Options

- Cylindrical printing capability.

- Three precision dial indicators mounted on X, Y, and angular micro adjustable table.

- Adjustable squeegee pressure with gauge and regulator.

- Off contact precision dial indicator.

- Dual print head for precise squeegee pressure for images 16” (406 mm) or wider.

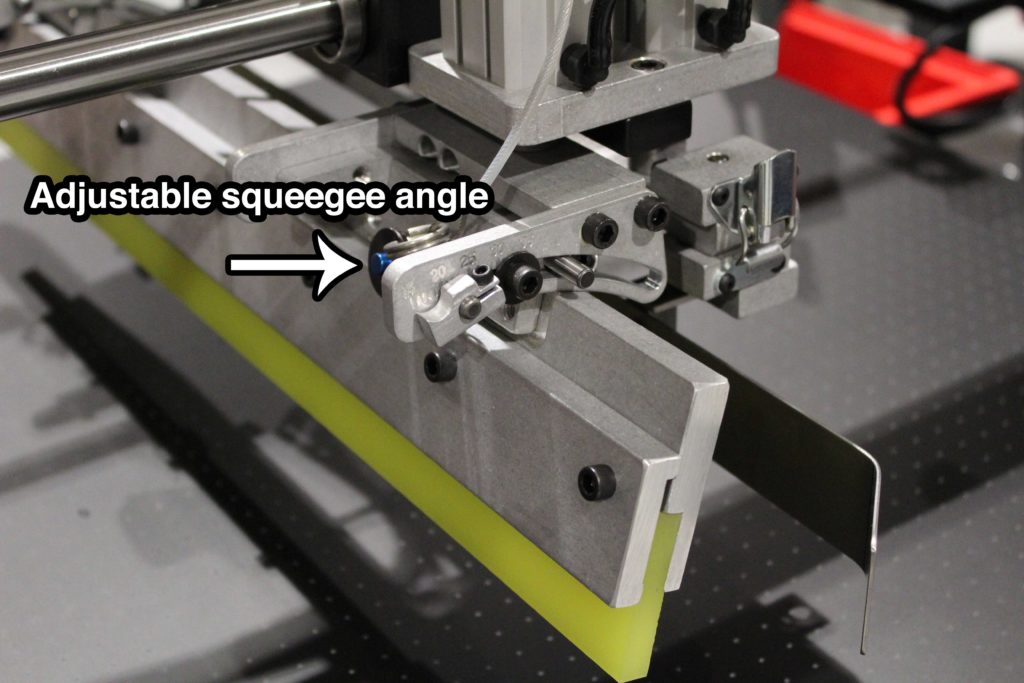

- Adjustable squeegee angle.

- Flood/print cycle replaces standard print/flood cycle.

- Automatic Ink Dispenser.

- Screen Tension Meter.

- Vacuum table.