Screen Printing on YOUR Plastic Cups

What to know about plastic cups

Whether they're for the home, disposable, or souvenir stadium cups, plastic cups offer your customers an affordable and efficient way to market their brand at an event or meeting. When screen printing plastic cups, pretreatment is not typically considered for ink adhesion due the short life of the cup use (unless if it is a reusable plastic cup which is dishwasher safe).

The ink you decide to use with your plastic cup printing machine will depend on your throughput and budget. If you are purchasing a T8-SS with integrated UV, you will be using UV inks which are easiest to work with as they do not dry to the screen unless left out with the light on over head (best to cover screen between uses). If solvent based inks are used then you can air dry them or expose them to forced air and IR to expedite the drying. UV provides you with an instant cure for your products so they can immediately go into packaging. Using solvent inks may take a few minutes to a few hours depending on if you are air curing or using forced hot air/ IR. The Model F1-DC is your semi-automatic solution for printing plastic cups and more. Once printed on the Model F1-DC, may either use a conveyor oven or the Model UVSP.

When you are looking at fixtures to use for placing your plastic cups on the machine prior to printing, it is important to make sure the tolerance for the sizes of cups you receive are made known by the manufacturer for your machine. You need your plastic cup to be hugging the fixture it is placed on for optimal prints and avoid any tooling that will affect the form of the plastic cup when the screen is moved down and the squeegee pushes the ink through the screen on the part. If there is space for the cup to bend, your image will be compromised. SA offers precision manufacturing, and prior to shipping we will show you that the machine works through test print videos using your product.

Plastic cups range in their thickness. If you are using a thin disposable cup that is typically used for parties and one time uses, it is advised you do not use forced hot air to cure your products to avoid any warping that may occur. Conventional UV curing may also cause warping but this can be mitigated by opting for UV LED. SA systems that use conventional UV are designed with your ability to control the amount of UV that your cup is exposed to and the time it is exposed for. We will work with you on finding the best process for your product.

Why Upgrade Your Screen Printing Machine For Your Plastic Cups?

Systematic Automation offers plastic cup printing machines for everyone, from new screen printing businesses to established shops looking to upgrade their machines. We offer an array of custom screen-printing machines built right here in the U.S.A. All machines listed below can print a variety of different sizes and product types so you are not limited to one substrate.

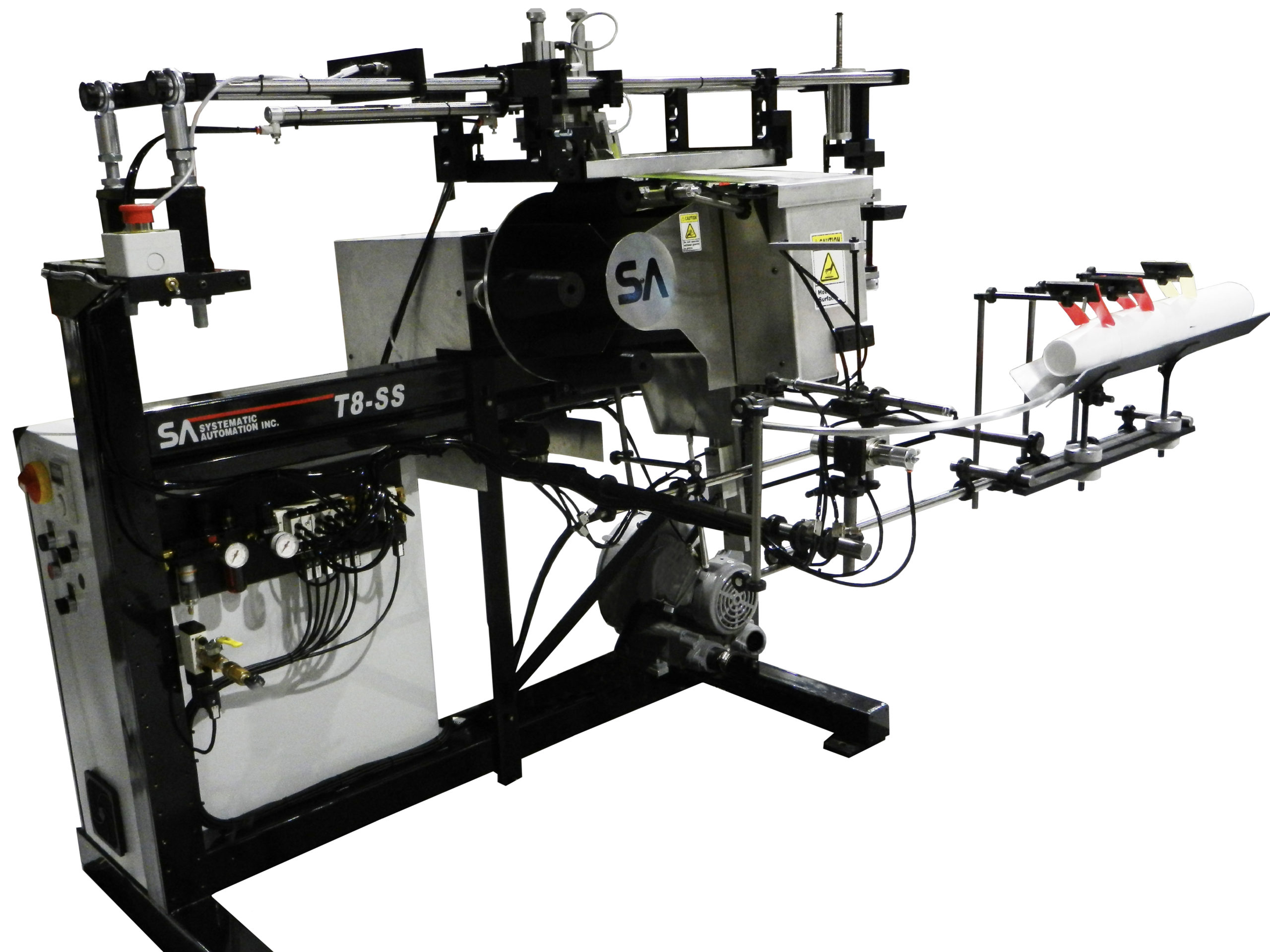

- Our Model T8-SS is the industry standard for automatic production printing for your plastic cups, from thin disposable cups to thicker stadium cups. Mandrels attached to the dial may be easily swapped for different sized plastic cups. Included with the machine is an integrated curing system. Flame pretreatment is optional for your machine. We use our Ultra Light UV system or Phoseon if you prefer LED. After the product is printed and cured, it is then unloaded and stacked for shipment. The T8-SS is engineered for the operator, including those with no experience screen printing.

- Our Model F1-DC is a versatile and easy to use machine quoted as being “The most reliable screen-printing machine ever made.” With fast and accurate printing and product change over in less than a second, this machine is perfect for the new and experienced printers alike. Tooling for plastic cups is simple and affordable. Swapping mandrels on your tooling fixture takes seconds and can't get any easier. Mechanical and optical sensors are available for multi-color registration.

- The Model Super ROI is your solution for screen printing multiple colors on your cups. Mechanical and optical registration are available depending on your cup type and means in which we register. Typically plastic cups can be molded to include a notch on the bottom that will provide a means of registration for multi-color prints. Optical registration may be used for registering the product based on color identification.

PLASTIC CUP SCREEN PRINTING HAS NEVER BEEN SO SIMPLE

- Ideal for cups, pint glasses, wine glasses, growlers, tubes, and more.

- The precision system allows for multicolor printing.

- Quick and easy product changeover in seconds.

- Approximate throughput of 3,600 parts per hour (depending on the article).

- Integrated UV and take-off system.

- Simple, reliable, easy to service.

- Machine tool quality and durability.

- Harmonic acceleration and deceleration of rotary indexer.

- Ideal for cups, glassware, bottles and oil filters.

- Servo driven indexer.

- Low maintenance lube free drive system.

- User friendly touch screen display.

Screen Printing Machines for Plastic Cups

-

F1-DC Screen Printing Machine

F1-DC Screen Printing Machine

Clamshell Printers For Cylindrical ProductsLearn More- Ideal for cups, bottles, glassware and more for full 360 degree image coverage.

- Quick and easy changeover between products in seconds.

- Approximately 3,600 prints per hour (depending on product).

- 100% air operation - cannot overload or burn out, or become obsolete.

- Brilliantly simple, easy to operate and versatile.

-

T8-SS Screen Printing Machine

T8-SS Screen Printing Machine

Turret Motion Printers For Cylindrical ProductsLearn More- Integrated UV and take-off system.

- Simple, reliable, easy to service.

- Approximately 3,600 parts per hour.

- Harmonic acceleration and deceleration of rotary indexer.

- Optional integration of automatic loaders, pretreatment and more.

-

Super ROI Screen Printing Machine

Super ROI Screen Printing Machine

In-Line Printers For Cylindrical ProductsLearn More- Ideal for cups, glassware, bottles and oil filters.

- Servo driven indexer.

- Approximately 3,600 prints per hour (depending on product).

- Modular design permits process integration.

Make the Right Choice for Your Screen Printing Business

Systematic Automation is your choice for professional custom screen-printing machines made here in the U.S.A. We offer an array of custom screen-printing machine models to handle all your printing needs. We also offer UV curing machines, vacuum tables, and heat treatment machines to ensure your printing shop can fill every order. We have experienced technicians that offer support to help set up your machine and any technical questions you have once you start printing. Call or contact us today to speak with one of our expert technicians and choose the right machines for your business.

Some of our satisfied customers