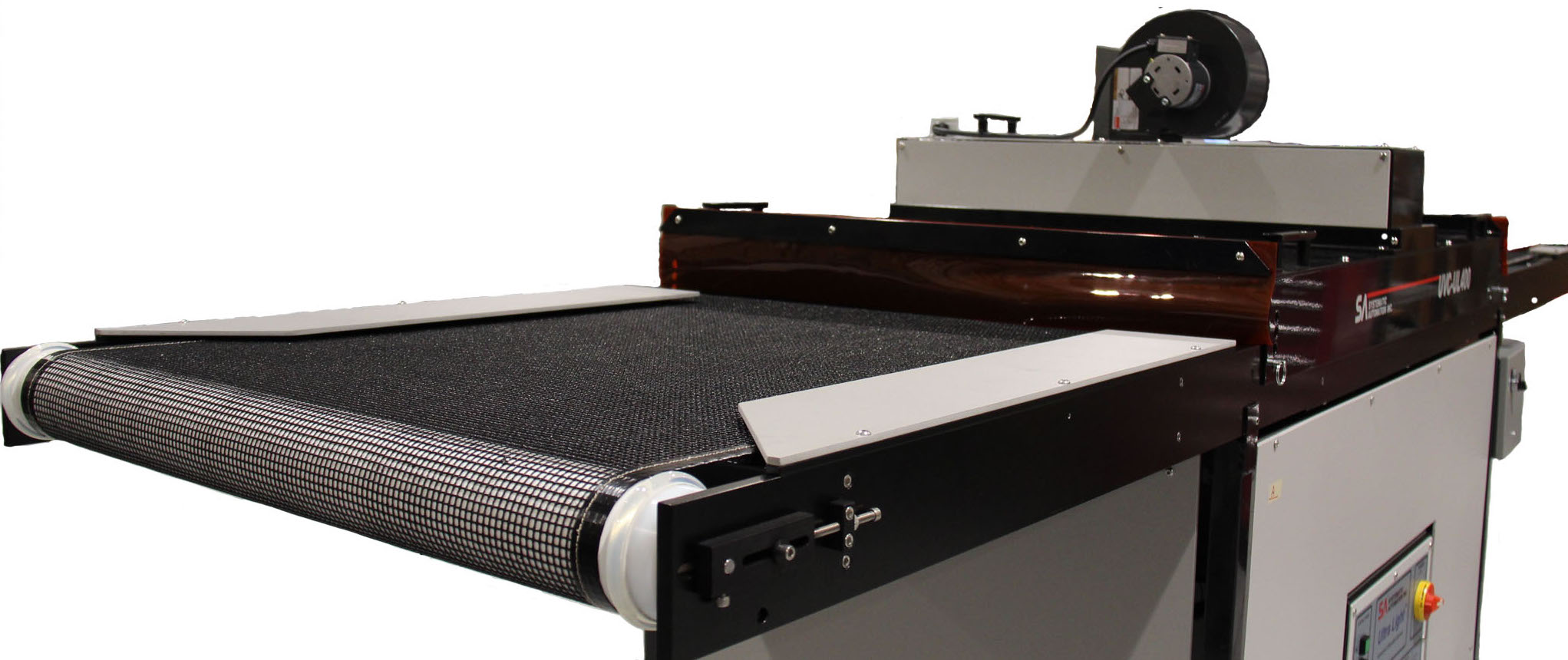

Ultra Light UV Conveyor

- Tri-Power 200/300/400 watts per inch power supply.

- Lamp sizes up to 40″(1010mm). Conveyor belt width sizes up to 144″(1450mm).

- Cooling air is drawn through unit by a blower.

- LED integration available.

- Adjustable lamp/LED module distance.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

- Product Description

- Features

- Featured In

- UV Curing Resins

- Industries Served

Product Description

Efficiency and Simplicity

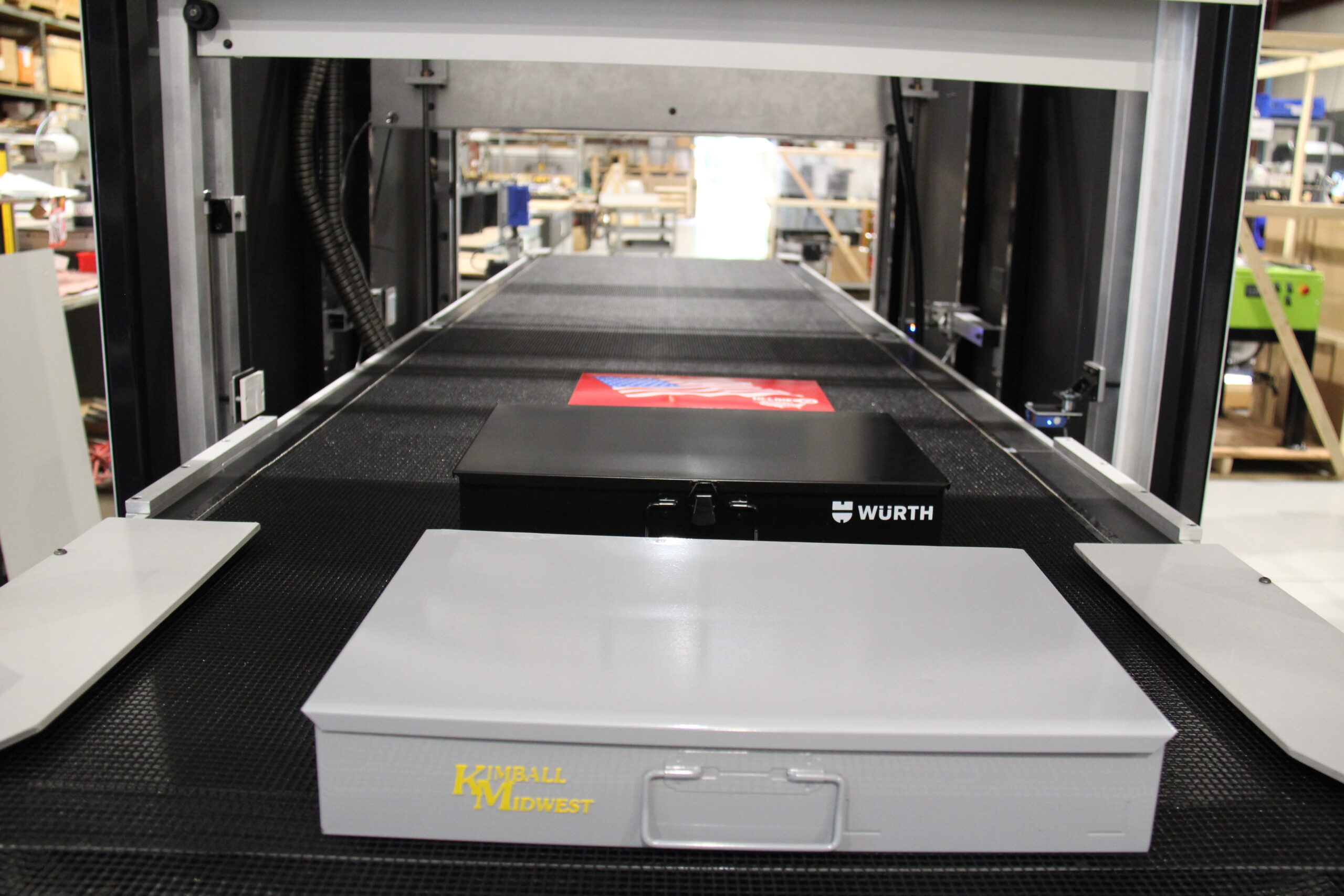

No other conveyor brings quality, durability, reliability and performance to the market like Systematic Automation. The UV conveyor is designed for curing coatings, adhesives and inks. It features our Ultra Light UV System delivering 400 watts per inch of curing power (tri-power 200/300/400 WPI). LED integration is available. UV conveyor belts are made in house for quick 2-3 day lead time.Conveyor belts may also be made to order per your size requirement.

Lamp Sizes Available:

3″(70mm) | 6″(150mm) | 12″(300mm) | 18″(450mm) 25″(630mm) | 30″(760mm) | 40″(1010mm)

Features:

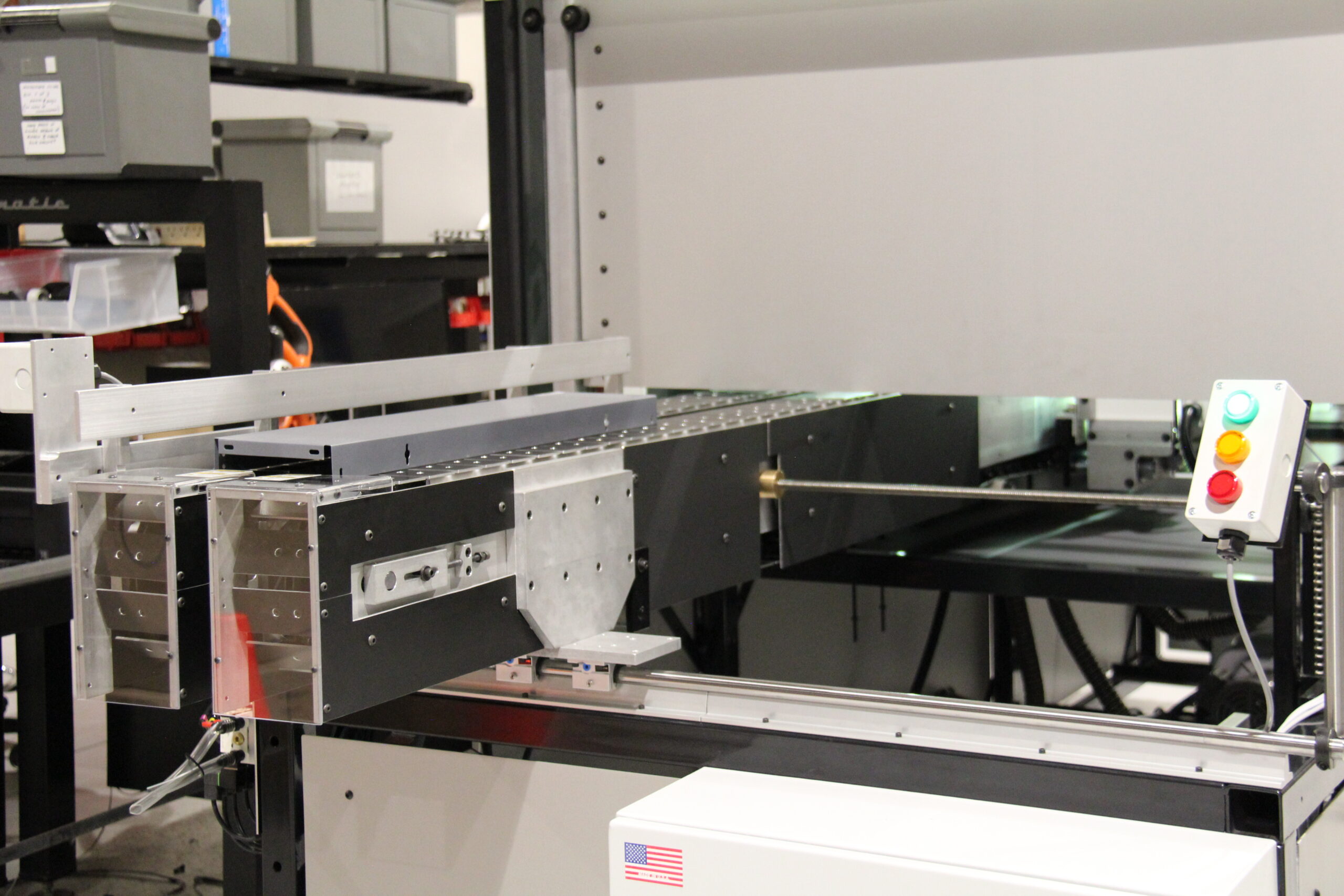

- Height adjustment for taller products, from 1” to 3.25” in .75” increments. Larger shrouds available to your specification.

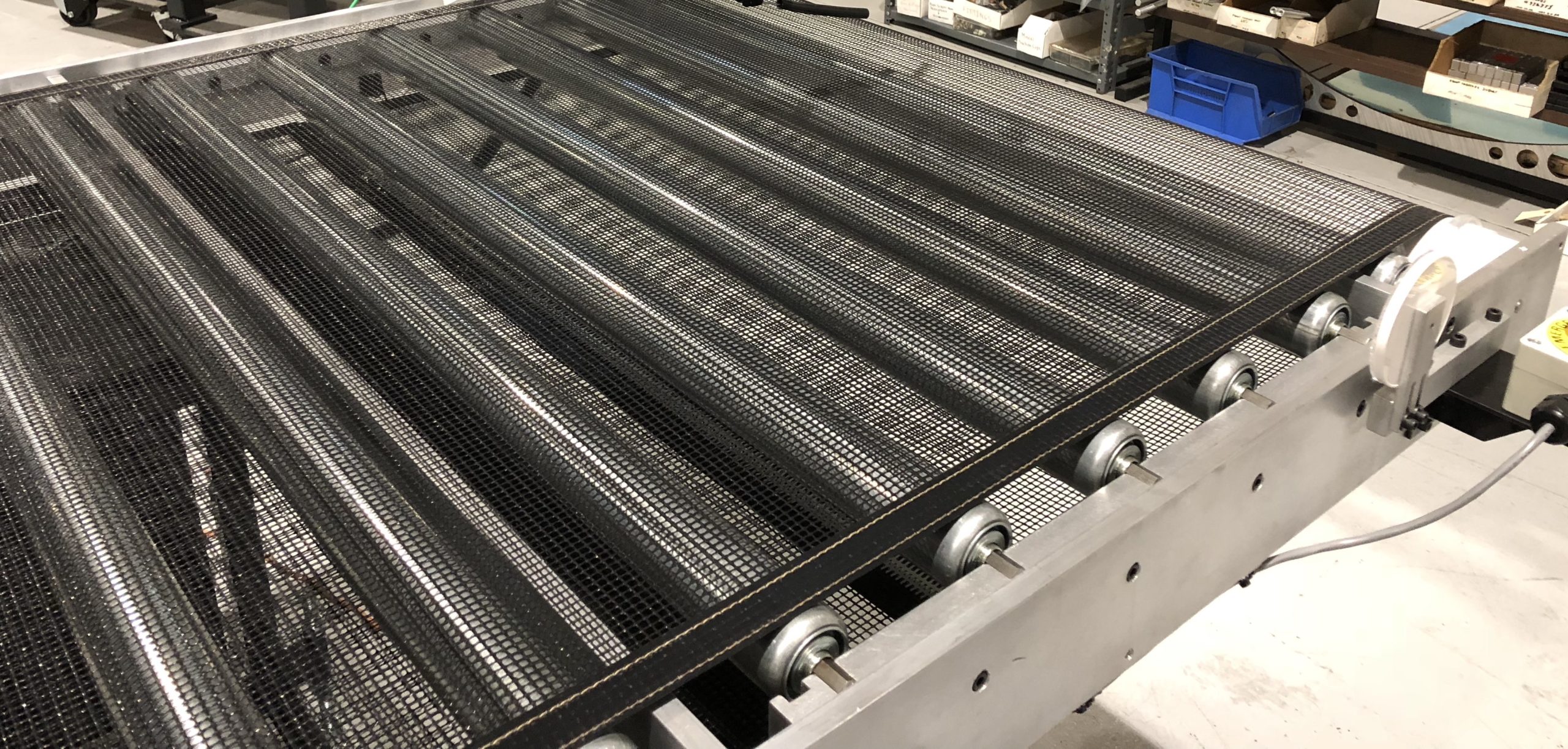

- Rollers under the teflon belt available for heavy products.

- Modular irradiator has adjustable focal point height.

- Special teflon coated belt for longer life than conventional belts.

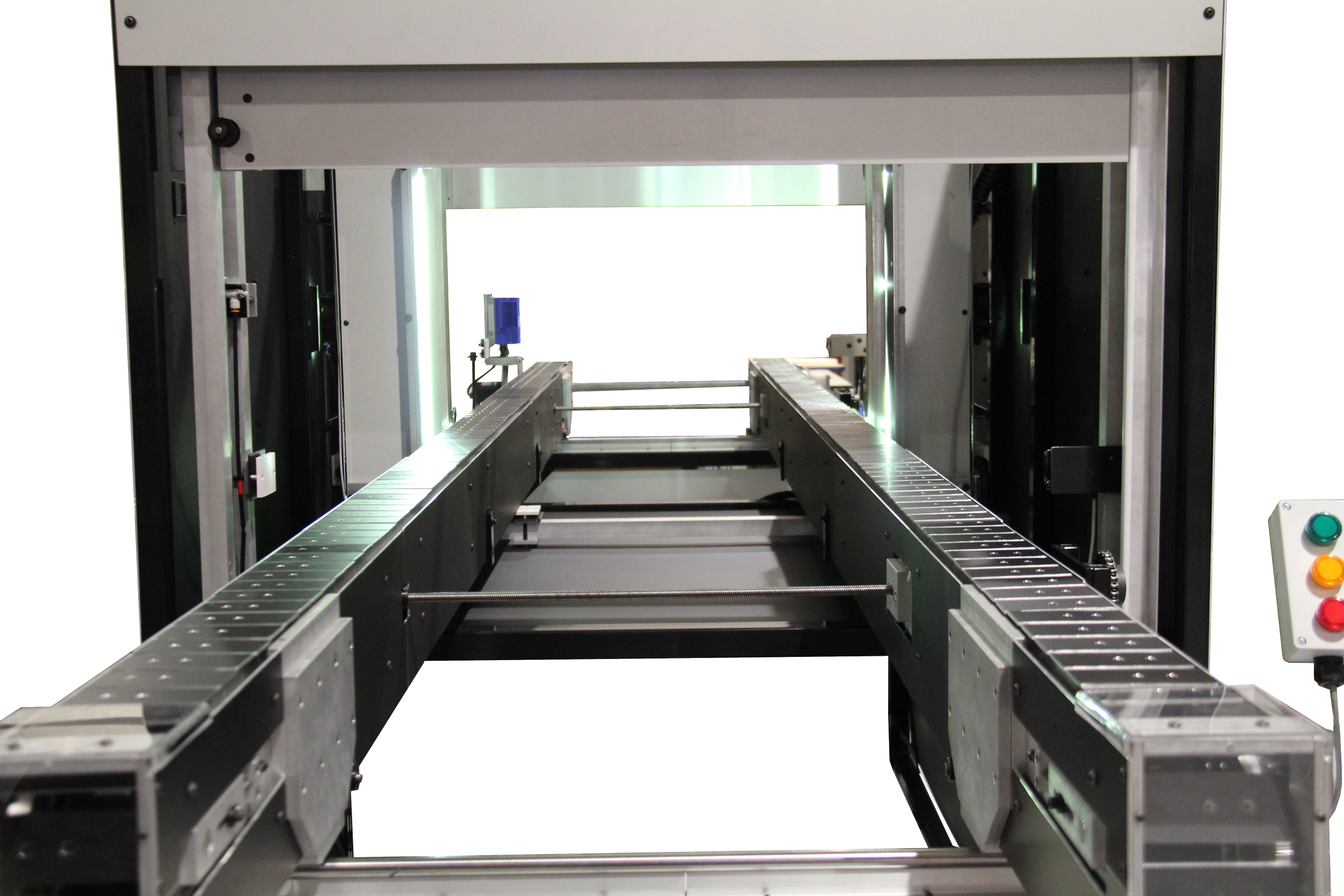

- Cooling air is drawn through unit by a blower to keep heat sensitive parts from warping or distorting.

- Standard conveyor speeds 1-50 or 1-10 FPM, specify your preference. Custom speeds available too.

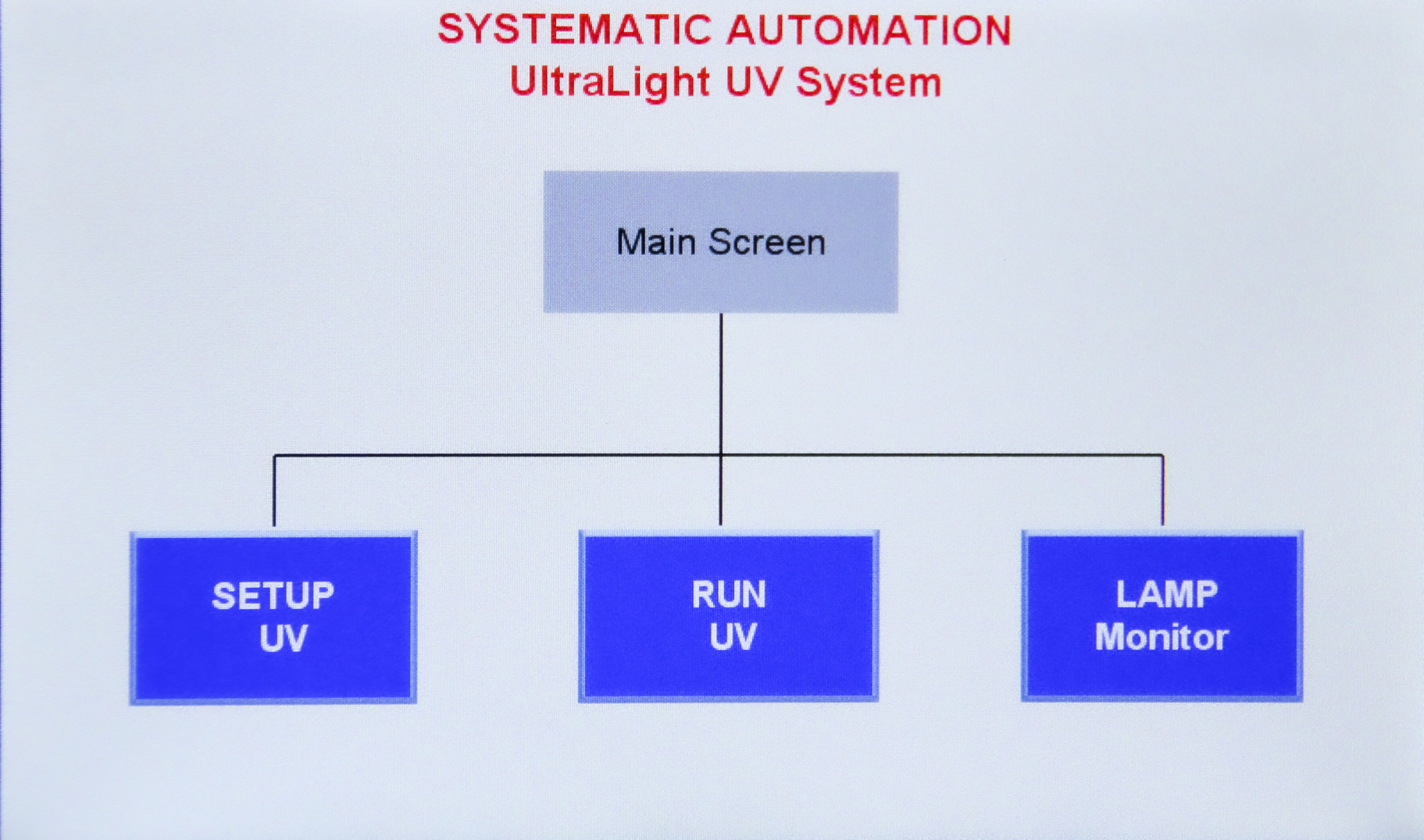

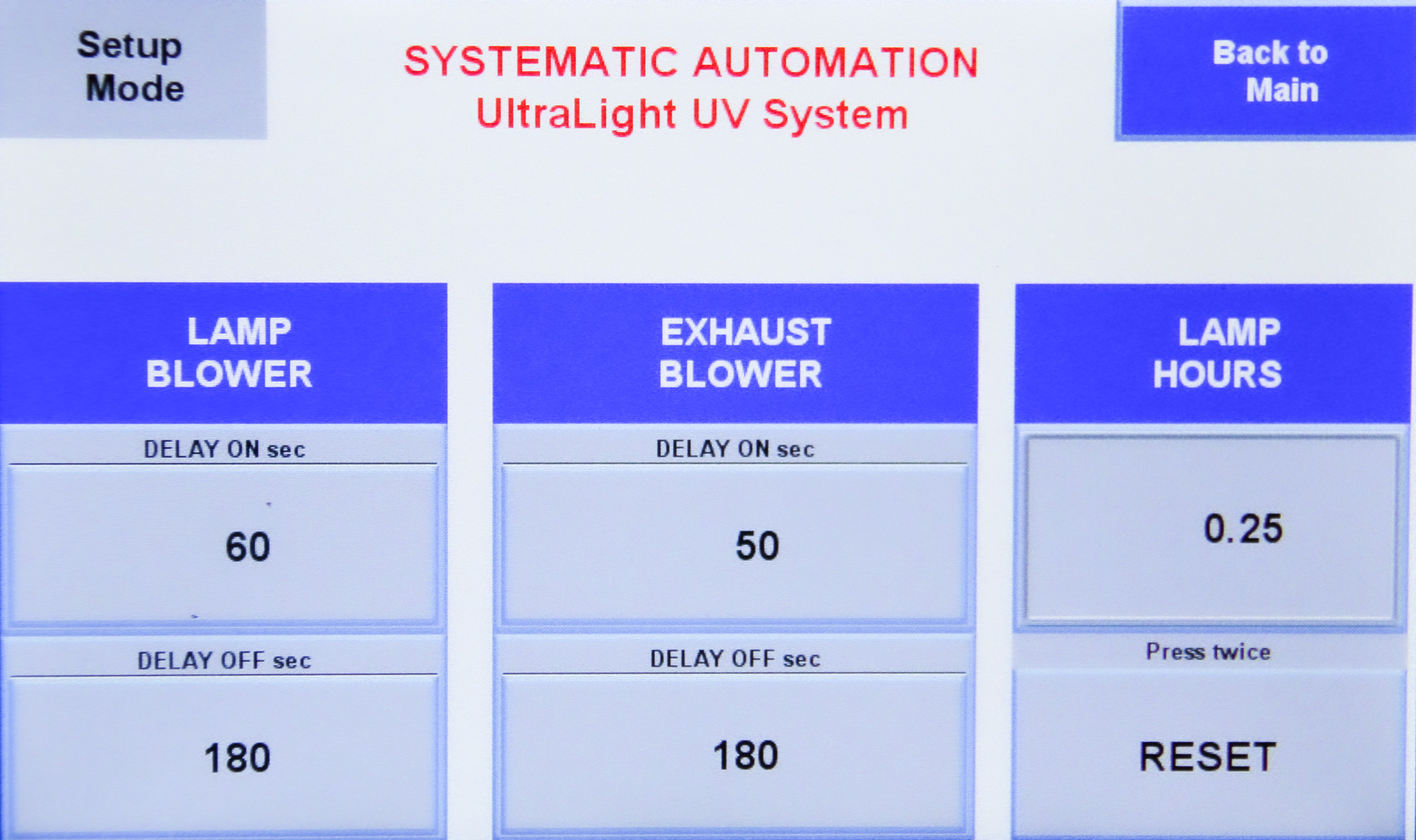

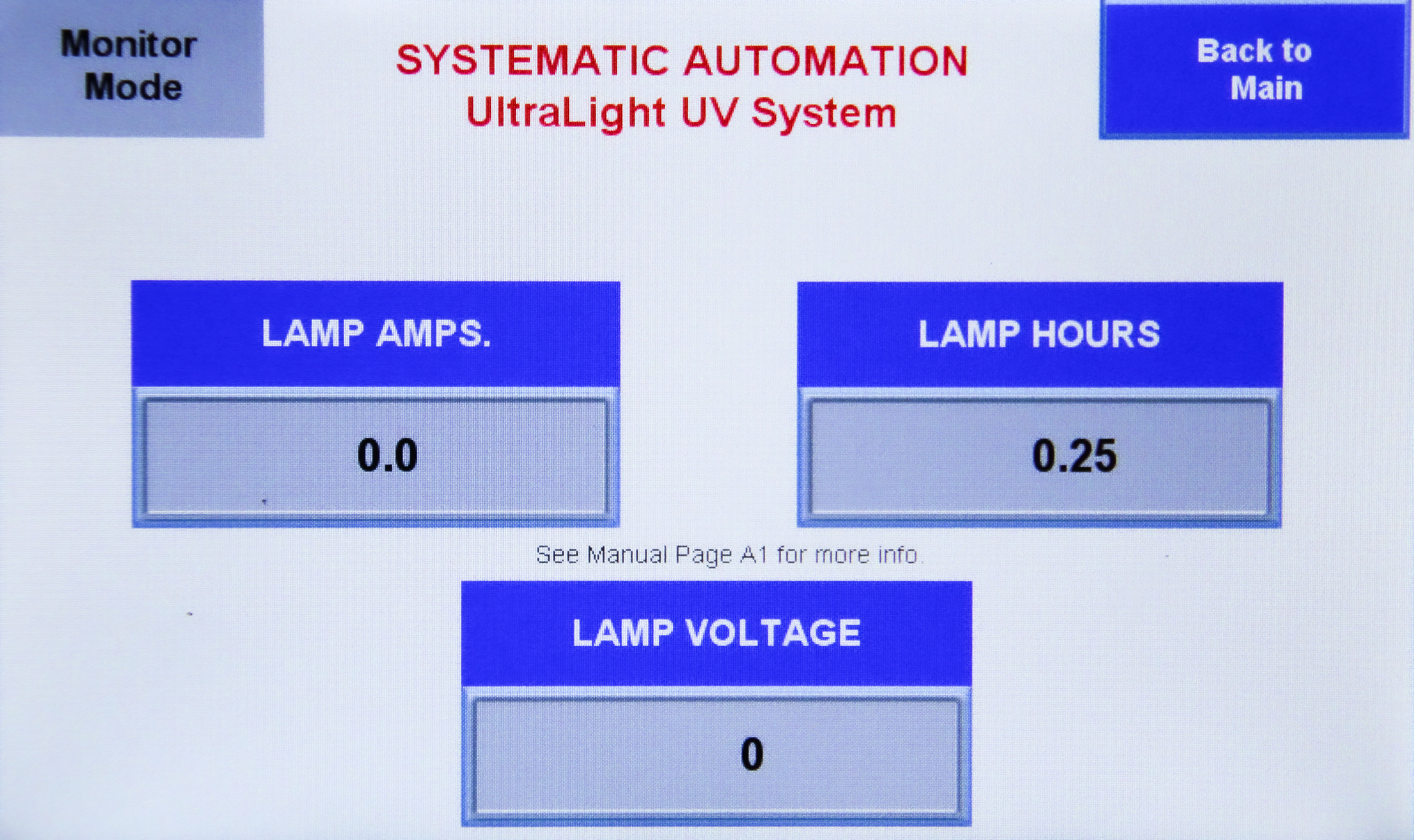

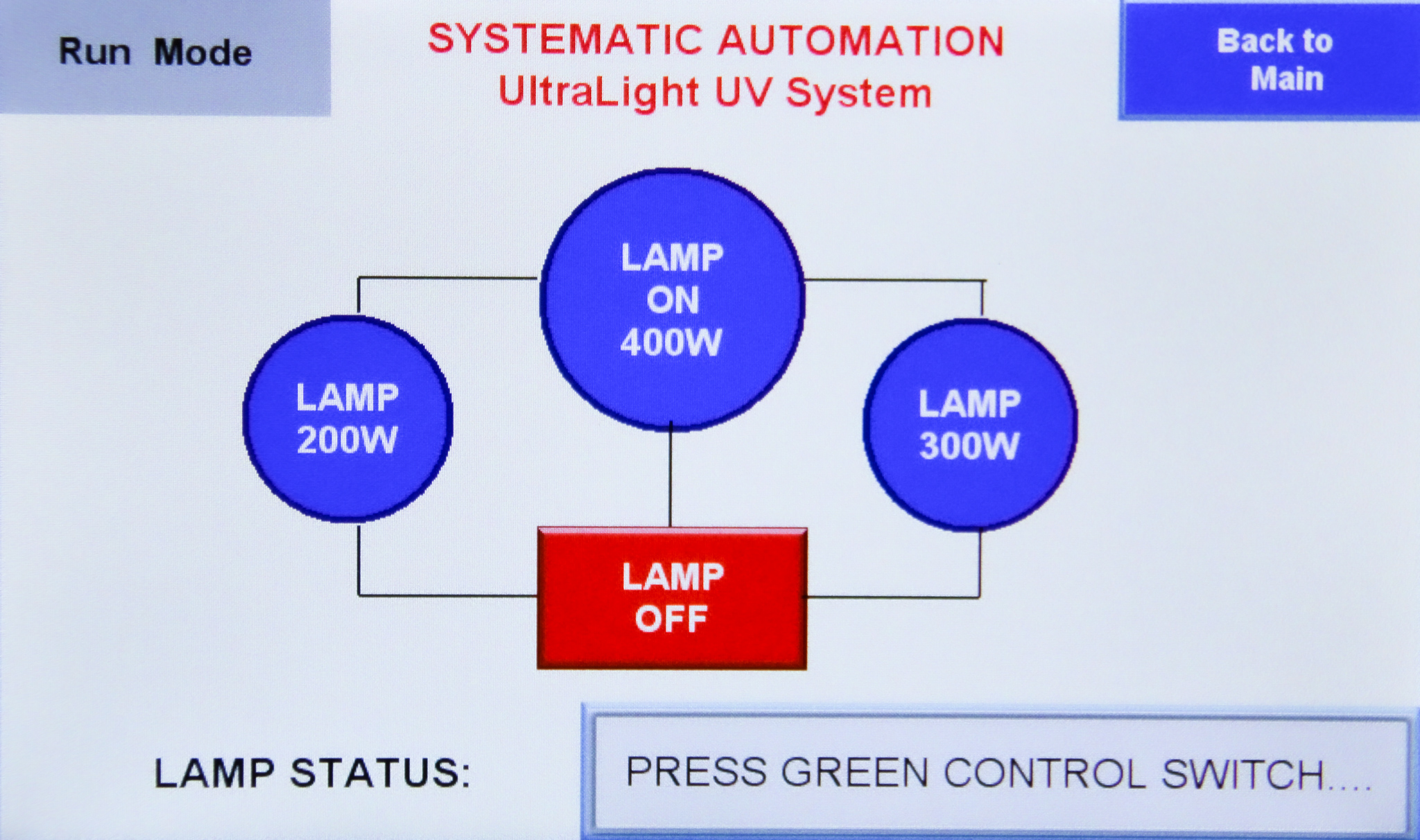

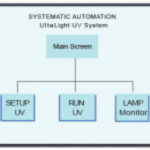

User Interface

Features

Engineering Features

- Supply Voltage – (220, 460 VAC) UV lamp, please specify your preference (110 VAC ) PLC & Conveyor.

- Tri-Power 200/300/400 watt per inch power supply.

- Touch screen controls.

- Mercury vapor lamp with Iron additive (D type). Mercury vapor (H type) also available.

- Revolutionary UV irradiator design for maximum possible energy efficiency.

- Digital display of conveyor speed, speed easily changed by up/down arrow keys.

- Programmable scale factor in different units.

- Standard conveyor speeds 1-50 or 1-10 FPM, specify your preference. Custom speeds available too.

- Relay output provided for interface to other equipment.

- Light shielding.

- Height adjustment for taller products, from 1” to 3.25” in .75” increments.

- Special teflon coated belt for longer life than conventional belts.

- Cooling air is drawn through unit by a blower to keep heat sensitive parts from warping or distorting.

- Unique conveyor pulley design for perfect belt tracking.

- Modular irradiator has adjustable focal point height.

- Adjustable legs for conveyor height position from 35.5″ (902 mm) to 42.5″ (1079 mm).

Standard Sizes

- UV curing system with 6″ UV lamp, 63″ long conveyor, 14″ wide belt.

- UV curing system with 12″ UV lamp, 63″ long conveyor, 14″ wide belt.

- UV curing system with 18″ UV lamp, 135-1/2″ long conveyor, 25-3/4″ wide belt.

- UV curing system with 25″ UV lamp, 135-1/2″ long conveyor, 32-7/8″ wide belt.

- UV curing system with 30″ UV lamp, 135-1/2″ long conveyor, 37″ wide belt.

- UV curing system with 40″ UV lamp, 135-1/2″ long conveyor, 47″ wide belt.

- Larger sizes available.

Featured In

- Adhesives Magazine

- Appliance Design

- Screen Printing Magazine

- R&D Magazine

UV Curing Resins

There are a variety of different resins with varying curing parameters. Some resins are organic, while other synthetic. The regulation on the types of resin and their potential for pollution as well as energy consumption involved in UV curing process are continually regulated, especially in countries with EU regulations. UV curable resins have been growing in popularity over conventional drying, which consumes more energy and conventional resins emit more waste into the atmosphere. Regardless of where your opinions on pollution stand, it is a good idea to future proof your equipment. Curing your resin will rely on the wavelength in which is cures with. Conventional UV systems cover a wide spectrum of wavelengths that will induce curing. UV LED systems use a fraction of the energy and cures the resign in one specific wavelength. UV LED resins are less common, but as we progress, so are the amount of UV LED resins available. Also, your UV LED resins are compatible with the conventional systems.

Industries Served

- Printing – Screen, Digital & Flexo

- Medical

- Industrial

- Electronics – Touch Panel, Mobile Phone, Etc..

- Adhesives

- Automotive

- Furniture