SCREEN PRINTING 101: WHAT TO KNOW

Screen printing is the process of pressing ink through a stenciled mesh screen to create a printed design. The screen printing technique is ideal for creating bold canvases, posters, and artwork, but it can also be used to print fabrics and textiles, so it can also be used for creating clothing and products.

Depending on the application method, screen printing can be referred to as serigraphy or silk screen, but they refer to the same basic method. Some advantages to screen printing include:

- Offers a higher quality than digital prints

- Suitable for long-term prints

- Can be applied to a wide range of print materials, such as glass, wood, textiles, signs, banners, and electronics

- Printing on specific areas of the print material is easy

How Does Screen Printing Work?

Screen printing involves the use of a mesh to transfer ink onto a substrate, except in areas blocked from ink by stencils. The screen's mesh open holes are filled with ink by moving a blade or squeegee across it. As the screen springs back after the blade passes, the ink wets the substrate and is pulled away. Several screens are needed to produce a multi-coloured image or design because each color is printed separately. This process of using a mesh based stencil can be used to apply ink onto substrates such as t-shirts, posters, stickers, vinyl, wood, or other material.

Tutorials For Printing Cylindrical Products

What Are The Benefits of Screen Printing In-House?

Screen printing equipment is an investment that pays for itself over time. By controlling quality, you will eliminate shipping costs, and obtain profits that your contract printer would otherwise retain, and eliminate the cost of shipping.

Our customers bring screen printing in-house primarily because they are having trouble outsourcing. You will be able to control delivery and quality. As part of your ability to respond quickly to your customers' requests, we can help guide you through the variables involved in printing.

What Supplies Do I Need to Begin Screen Printing?

You only need a screen and ink. Our team of experts will assist you in selecting the right screen and ink specifications for your product. After finishing your print job, you can clean your screen with products like EZ Solv.

The Screen Printing Process

What are Screen Frames and How Do They Work?

The quality of your screens is crucial to the success of your printing process. In order to ensure quality control and minimize downtime when a screen rips while printing, you may want to consider bringing screen making in-house along with your screen printing machine.

In a standard screen frame, the mesh is tensioned and glued on. A thin coat of emulsion is applied over the screen mesh after it has been applied. An image is then applied to the emulsion, followed by a final cure using light exposure (the image is not permeable to UV light). Lastly, a pressure washer is used to remove the uncured emulsion from the image-covered areas of the screen. Ensure that the screen is coated with emulsion, except for the image. Ink can now be pressed through the image onto your product.

What you need:

- Screen frame: built to 3" beyond the image on each dimension (x,y).

- Screen mesh: Your ink will dictate the size emulsion. Air dry inks will require a lower TPI (approx. 150-280) while UV ink will require a high TPI (approx. 305-420).

- Image on film: You will need to print your image on a piece of film, center it on the screen and coat the screen with emulsion prior to burning.

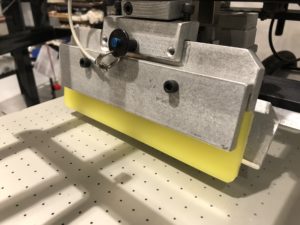

What is The Squeegee And How Does It Work?

Squeegee materials are typically made of polyurethane, which is highly resistant to harsh chemicals found in screen printing ink. After flooding the ink over the screen image, the squeegee presses the ink through the image and onto the product by applying pressure to the squeegee.

Squeegee material comes in different hardness levels, also known as durometer ratings. In the screen printing industry, durometers range from 60 to 90 with 90 being the hardest. The most commonly used squeegee for graphic printing material is 70 durometer.

Discover more screen printing squeegee tips and information.

The Screen Printing Process Step-by-Step

The screen printing process varies depending on several factors including what type of machine you use and for what application. In general, there are a number of common steps involved in the process. These steps include:

- Design Prep: The first step to screen printing is to create the design. Screens and stencils are created by printing a design onto an acetate film, then using it to create a screen or stencil.

- Screen Prep: This step will help you prepare the screen to carry out further operations. After determining the appropriate screen mesh for your project, the screen is cleaned and dried, then coated with a light-reactive emulsion.

- Screen Exposure: It is very important to place the transparent acetate film carefully on the emulsion-coated mesh screen so that the emulsion can harden and become developed under a bright light. For designs involving multiple colors, it may be necessary to use separate screens for each color. Once you have a functional screen that is cured and cleaned and ready to use, then you can begin the screen printing process.

- Screen Print Process: In preparation for printing, the material to be printed is placed into the machine alongside the screen. This is the step where the printed design comes to life. A layer of ink is applied to the top of the screen in the desired color. Through the use of a squeegee, the ink will be evenly distributed over the screen's length. Ink transfers from the stencil to the underlying material, printing the design on the product through the open areas of the stencil.

- Heat Curing and Finishing: Last but not least, the printed product is cured (method determined by ink choice), creating a smooth finish.

- Screen Frame Reclaim: After printing is complete, the screen frame should be rinsed with water on both sides, and then emulsion remover is applied. The 'print side' of the screen frame should be pressure washed until all emulsion has been removed.

Screen Printing Inks

What Screen Printing Inks Should I Use?

A product's adhesion and opacity must be considered when choosing an ink. The ink used for screen printing tee shirts, for example, must remain opaque despite being washed repeatedly. It is also important that the ink used for printing on drinkware can withstand being washed repeatedly while still adhering to the glass. In some cases, pretreatment may be required for adhesion prior to printing.

There Are Three Standard Types of Inks:

- Water base - air dry (may require heat for expedited cure): The ink consists of water and pigment, making it the most environmentally friendly type of ink on the market. Some prefer the appearance of waterbed ink from the washed out feeling they may provide after being washed. The ink tends to fade faster than solvent or UV based inks. They are also used for inks that are intended to peel off. The ink can be air dried or force hot air dried.

- Solvent base – air dry (may require heat for expedited cure): If you are printing an image with opacity and adhesion being important factors, solvent inks are for you. Commonly used with glassware due to their ability to withstand dishwashers. You will need to keep the ink moving on the screen (printing), otherwise the ink could dry to the screen. The ink can be air dried (may take a few hours) or put through a conveyor oven.

- UV – requires a UV curing machine – cure/dries instantly: Ideal for large work loads. Some benefits to UV inks is that they are becoming more prevalent for screen printing. They do not dry to the screen and if covered, they can stay in the screen over the night and stay in a liquid state. You will require a UV curing system, either conventional or LED depending on the ink you decide. Pretreatment may be required for adhesion. Curing is instant when exposed to UV light.

There are many manufacturers of UV and conventional inks for specific types of product surfaces. However, some surfaces will not provide adequate ink adhesion without proper pretreatment exercises. Glassware, for example, typically requires pretreatment before screen printing.

What is the Importance of An Ink Adhesion Test?

Using the adhesion test, you can determine the type of ink to use for a particular application based on whether the ink demonstrates good adhesion.

You must ensure that your ink will stick and stay put after exposure to time, light, washing, temperature changes as part of your quality control process, and any chemicals in the product. SA can guide you through ink compatibility and surface preparation or pretreatment.

However, it is important to note that in some cases Fierosil adhesion may be better suited for providing optimal adhesion of inks to your chosen substrate. It is typically used on glassware, but there are many other items that have poor surface tension that can also be treated with Fierosil. Additionally, it can be used to pre-treat UV inks, which generally don't survive dishwashers or scratch off after printing.

How Do I Prevent Solvent Based Inks From Drying to the Screen, Causing Them to Rip?

Air drying solvent based inks require checking the surroundings of your printer for anything blowing air, such as open windows, fans, and air conditioning. Always keep the screen flooded. It is also possible to use additives that promote flow.

Note this issue will not occur with UV inks.

Additives

You may want to include additives with your ink. There are a variety to choose from depending on your process such as reducers, thickeners, adhesion promoters and more. When you purchase a machine from Systematic Automation, we will assist you in the process of choosing the right inks and/or additives for your product.

Pretreatment

When to Pretreat

Using a pretreatment will help your product to look better. Although your print may look fine without pretreatment, colors and designs will appear more detailed and vibrant with a pretreatment base. Applying dark shades requires something to adhere to in order to keep them looking sharp and clean.

When printing white ink on a surface, you must use pretreatment. It is particularly important to pretreat the white ink in order to maintain its adhesion to the surface of the product. The purpose of this step is to create an optimal surface on which the colors will be printed. The result is a brighter and more detailed white, and like printing on a light-colored surface, the details are more apparent.

To succeed in your new business opportunity and to produce a product you can be proud of and your customers will enjoy, you must incorporate pretreatment into your print jobs. Systematic Automation offers a 360 degree flame pretreatment system.

Curing

How to Cure Screen Printing Inks?

There are a few different methods of drying or curing screen printing inks. These methods are dependent on the ink themselves.

Water and solvent based inks are air dry and sometimes require a baking process for optimal adhesion and durability. A baking process is typically a conveyor with a heated tunnel that bakes the printed ink between 300°F and 450°F for a specified amount of time given by the ink manufacturer.

UV curable inks may be cured through conventional UV or LED UV. Once the printed ink has been exposed to the UV light, the ink will instantly cure and allow handling. UV curing machines come in different styles from conveyors to carousel units. Product shape, size and throughput requirements can help determine which style of machine fits best for your application.

Best Screen Printing Machine for Your Process

What is the Difference Between Flat Printing and Cylindrical Printing?

Flat printing means the substrate's printing surface is flat. Cylindrical printing means the substrate's printing surface is round. The rest of the substrate can have any shape to it.

When screen printing a flat surface, the screen is stationary above the printing surface about 1/16” (off contact). The squeegee presses the screen down to the product, then slides across the image on the screen and presses the ink through the image and onto the product.

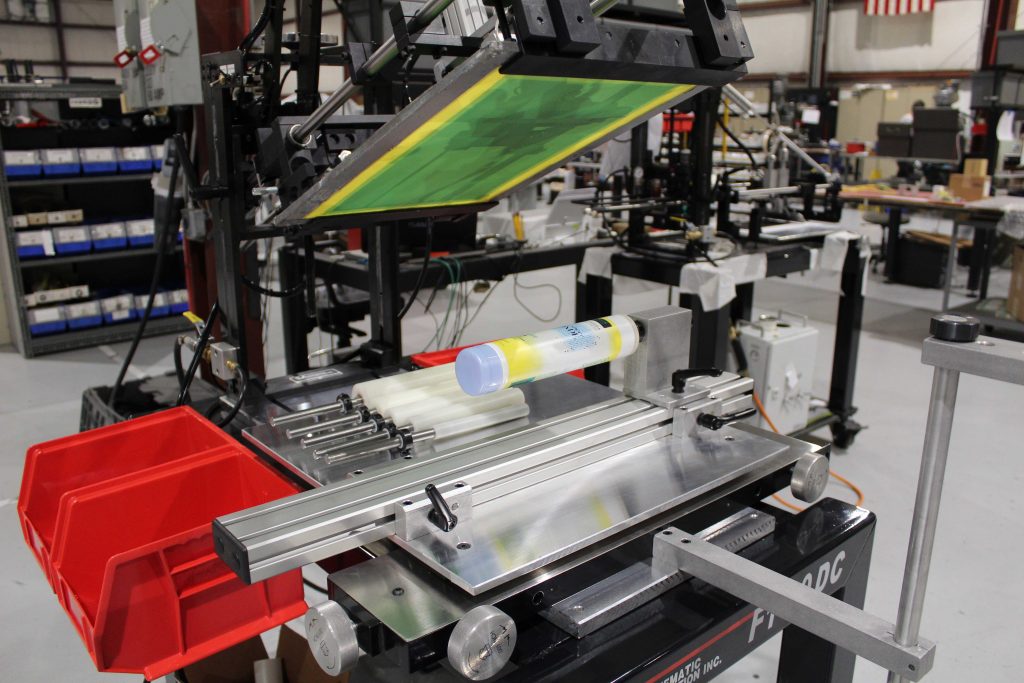

When screen printing a cylindrical substrate, the screen is positioned approximately 1/16” above (off contact) the printing surface. The squeegee stays stationary and presses the screen down to the product, then the screen moves while the product spins at the same speed using the squeegee to press the ink through the image on the screen and onto the product.

Is My Screen Printing Machine Limited to Printing Only One Type of Product?

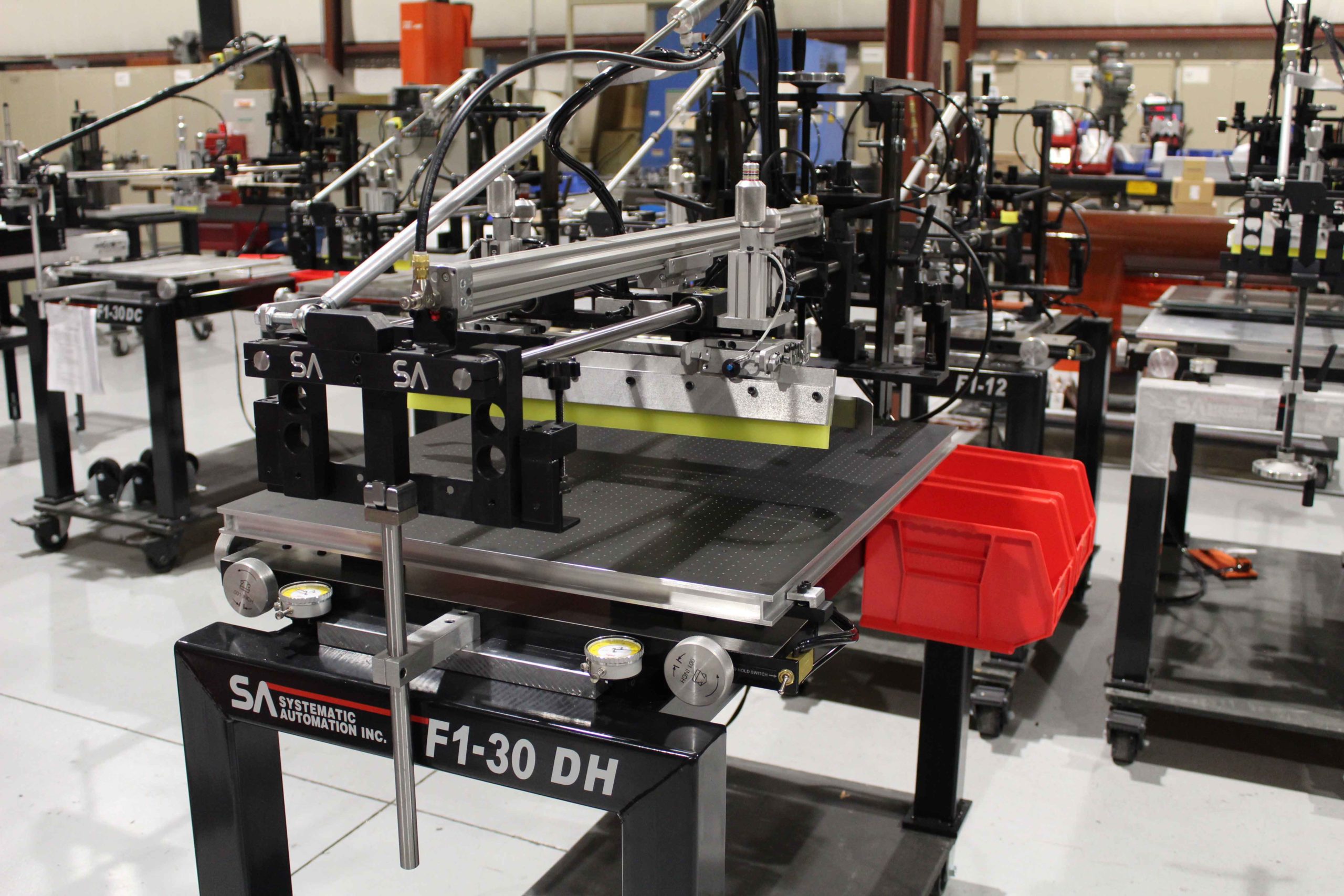

The modular design of Systematic Automation printers gives you the freedom to print a variety of products. For instance, printing flat to cylindrical can be done in less than a minute with the Model F1 — changing between pieces of cylindrical tooling only takes seconds.

Which Screen Printing Machine Will Give You the Optimal Result for Your Screen Printing Process?

Clamshell Screen Printing Machines

Clamshell printers are a type of semi-automatic screen printer which looks like a clamshell. At Systematic Automation we offer two versions of this machine, the F1 and the F1-DC.

F1 SCREEN PRINTING MACHINE

The Model F1 is one of the most popular screen printing machines because of its versatility and ease of changing from flat to a cylindrical printing design. The F1 Screen Printing Machine is perfect for printing on canvas, cups, posters, glass, plastic bottles or any other items that are either flat or cylindrical.

F1 Screen Printing Machine

F1-DC SCREEN PRINTING MACHINE | CYLINDRICAL PRODUCTS

Known as "the most reliable screen printing machine ever made". It's brilliantly simple. Simple to use. As well as versatile. Built for demanding production and designed for simplicity, this machine will be a great addition to your shop floor. A cylindrical product such as a cup, pint glass, wine glass, growler, etc., is the perfect application for the F1-DC.

Harmonic Lift Screen Printing Machines

The harmonic lift table is a platform capable of holding materials and raising, lowering, and adjusting them to any height to meet the needs of an application.

KEG SCREEN PRINTING MACHINE

With the KEG Screen Printer, you can print on stainless steel kegs, Finn Kegs, RSR Kegs, Optikegs, Wine Kegs, Growlers, and CO2 tanks with ease. Additionally, it can print up to four colors simultaneously on one screen using our multi-color printing attachment.

HLT SCREEN PRINTING MACHINE

The HLT is powered by the Harmonic Lift Table for smooth, fast, vibration-free operation. A wide print area and best-in-class print quality make the HLT an ideal choice for printing rulers, plaques, panels, 3D products, and more. X, Y, and angular motions are independently micro-adjustable.

In-Line Screen Printing Machines

As their name implies, these machines have premium capabilities. The line screen production of these machines is the best in the industry, which indicates how many halftone lines are printed per linear inch. A printer's ability to reproduce photographic images is measured by this important metric.

PEN SCREEN PRINTING MACHINE

You can automatically print your pen catalog with the PEN Screen Printer. You will be able to print approximately 4,200 pens per hour using the PEN Screen Print Machine.

PRINT BELT SCREEN PRINTING MACHINE | FLAT PRODUCTS

Designed for flat products, the PRINT Belt is a turn-key in-line automatic screen printing machine. A revolutionary design eliminates the need for tooling or extra fixtures in order to produce multi-color precision printing.

CC-5000 SCREEN PRINTING MACHINE | CARD PRINTING

With the Systematic Automation CC-5000 Card Printing Machine, all types of flat card materials can be printed in production. It can be used for cards, poker chips, tokens, nail files, and more. Servo integration is available upon request.

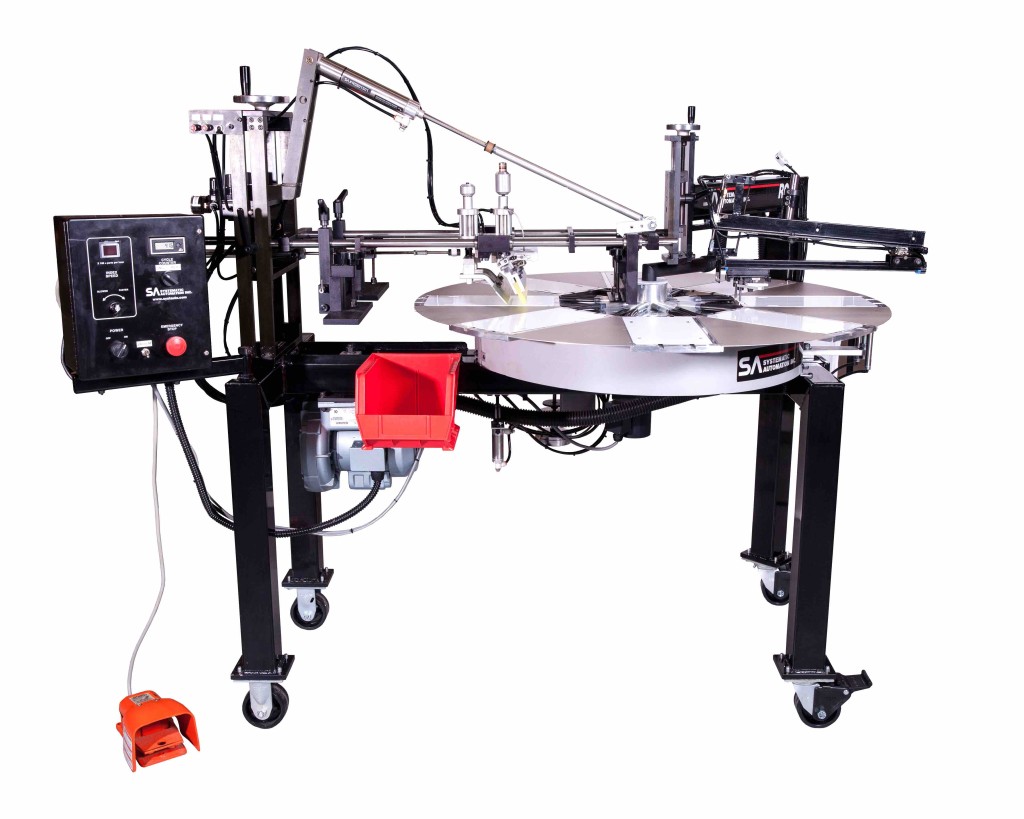

SUPER ROI SCREEN PRINTING MACHINES | CYLINDRICAL PRODUCTS

In the years to come, the Super ROI will faithfully produce optimal screen prints. This printer is ideal for printing cups, glassware, bottles and oil filters due to its utterly simple and modular design.

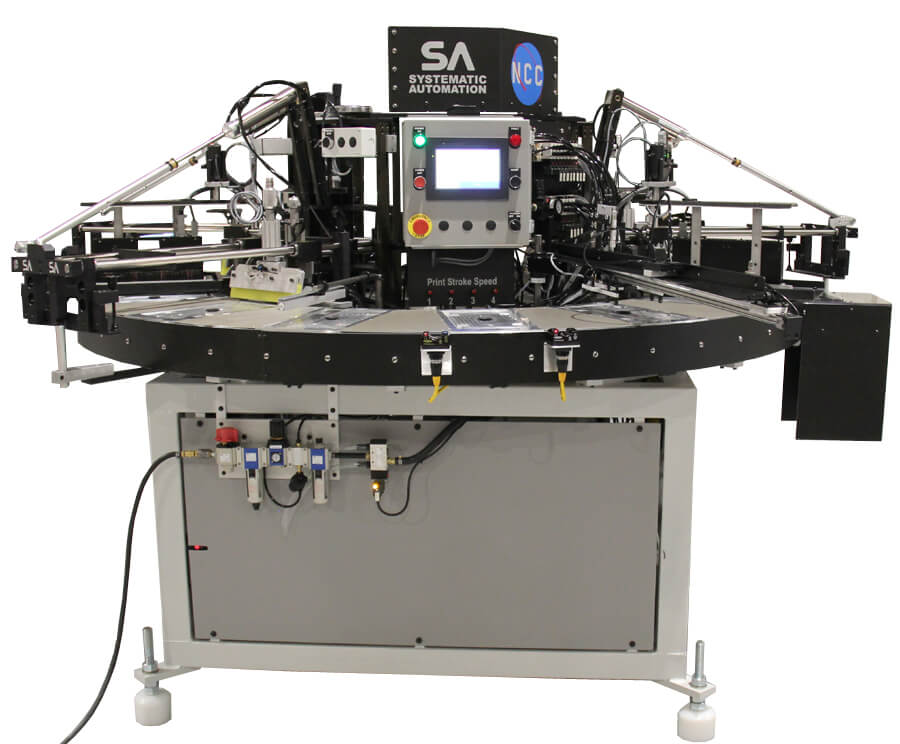

Rotary Index Screen Printing Machines

Rotary machines are ideal because they provide automatic multi-color printing in a compact package.

RC-1 SCREEN PRINTING MACHINE | FLAT PRODUCTS

The rugged and dependable RC-1 provides operators with great flexibility at an affordable price, offering high speed and accuracy. A smooth acceleration and deceleration of the dial motion is ideal for license plates, 3D products, shoe insoles, and more.

NCC SCREEN PRINTING MACHINE | FLAT PRODUCTS

This screen printer (US Patent # 5,784,932) offers superior performance compared to most other screen printers. Servo motor drives and reducers of the highest quality are used, and its modular design allows for easy modification and integration.

MICROSCOPE SLIDE SCREEN PRINTING MACHINE

Systematic Automation has developed a fully automatic precision Microscope Slide Printer that allows you to print perfectly printed slides in exact order quantities, all automatically. A Servo-driven rotary indexer virtually eliminates glass chipping.

Sliding Table Screen Printing Machines

These machines offer unobstructed product set up. Once the product is set on the sliding table, actuate the print cycle and the product will move beneath the print station and come back to the operator with the finished product for pick up. These machines are ideal for cumbersome products.

SX SCREEN PRINTING MACHINE | FLAT PRODUCTS

Using a unique patented design, the Systematic Automation Model SX is the thoroughbred of multicolor in-line UV presses. The SX allows full edge-to-edge printing of substrates. An aircraft grade honeycomb vacuum table advances from printer to printer in a continuous flow of production.

SST SCREEN PRINTING MACHINE | FLAT PRODUCTS

In one machine cycle, the Model SST can screen print up to six colors with precision and accuracy. With the SST, you can change the sequence of color laydown without moving screens, squeegees, or flood bars. The user-friendly touch screen interface automatically doubles or triples color printing for panels, windshields, sheet stock, plaques, and more.

Turret Motion Screen Printing Machines

Turret motion printers are ideal for high production. Eight products can be loaded onto the machine at once. Automatic integration is available such as automatic take-off and integrated UV curing.

VINCI 1452 SCREEN PRINTING MACHINE | CYLINDRICAL PRODUCTS

A Vinci 1452 screen printing machine is one of the fastest machines on the market. Running and maintaining this machine is extremely simple thanks to the unique, high speed indexer and cam-based controls.

T8-SS SCREEN PRINTING MACHINE | CYLINDRICAL PRODUCTS

Model T8-SS is a compact profit center that provides years of reliable service. It includes UV and pick-up systems. Easily serviceable, simple, and reliable the machine tool quality and durability is perfect for novice operators and experts alike.

How to Use a Screen Printing Machine

Operating Your Screen Printing Machine

Learning how to operate your specific screen printing machine is another crucial aspect of the screen printing process. We put together a guide to help give you an in-depth understanding of the various components and how to use your SA screen printing machine.

From Intermediate to Advanced, Systematic Automation Has The Screen Printing Machine You Need

As the World’s largest manufacturer of precision screen printing machines, Systematic Automation can provide the right screen printing machine for any application. If you have any questions about our screen printing machines, please do not hesitate to browse our products and application pages to learn more or give us a call at (860) 677-6400. We will be happy to assist you.

SOME OF OUR SATISFIED CUSTOMERS

Enhancing Inkjet Printing Adhesion: The Fierosil System Revolutionizes Drinkware Treatment

For drinkware printing, ink adhesion is paramount. Whether it’s intricate designs on packaging or vibrant graphics on marketing materials, achieving optimal print quality requires preparation, especially when it comes to printing on drinkware that will be repeatedly go through the dishwasher. Inkjet printing on drinwkare demands a delicate balance of substrate treatment to ensure ink…

Read MoreThe Significance of Silica Pretreatment

The Fierosil Silica Pretreatment System will provide your images with opaque, durable and cost effectiveness results . Silica pretreatment stands as a cornerstone process, offering a myriad of benefits that elevate the quality and durability of printed designs. In this article, we delve into the importance of silica pretreatment before screen printing and explore why…

Read MoreYour Everyday Devices: Screen Printing with Conductive Ink

In the dynamic world of electronics manufacturing, innovation knows no bounds. One such revolutionary advancement is the utilization of conductive ink in screen printing—a technique that is reshaping the landscape of electronic product design and production. In this article, we delve into the fascinating realm of screen printing with conductive ink, exploring its diverse applications,…

Read MoreScreen Printing Inks for Plastic Cups

what are the best screen printing ink for plastic cups. When it comes to branding your business, one of the most effective ways to do so is by using custom printed plastic cups. These cups not only serve as a functional item for your customers, but they also act as a walking advertisement for your…

Read More