Ultra LED UV Conveyor

- Custom conveyor/LED size to your specification.

- Programmable scale factor in different units.

- Best in class energy efficiency.

- Unique conveyor pulley design for perfect belt tracking.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for? Feel free to browse by screen printing application.

- Product Description

- Conveyor Features & Sizes

- Industries Served

Product Description

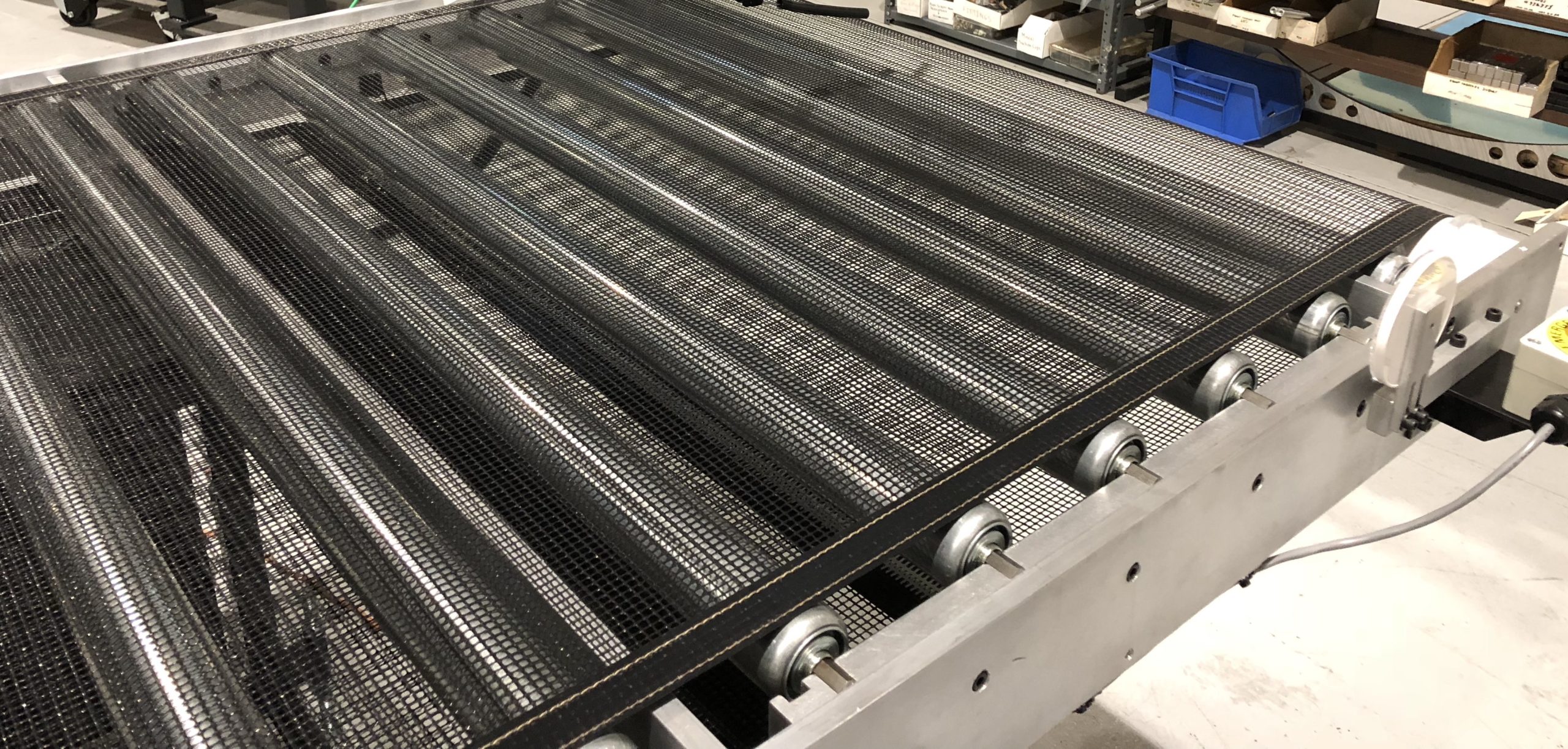

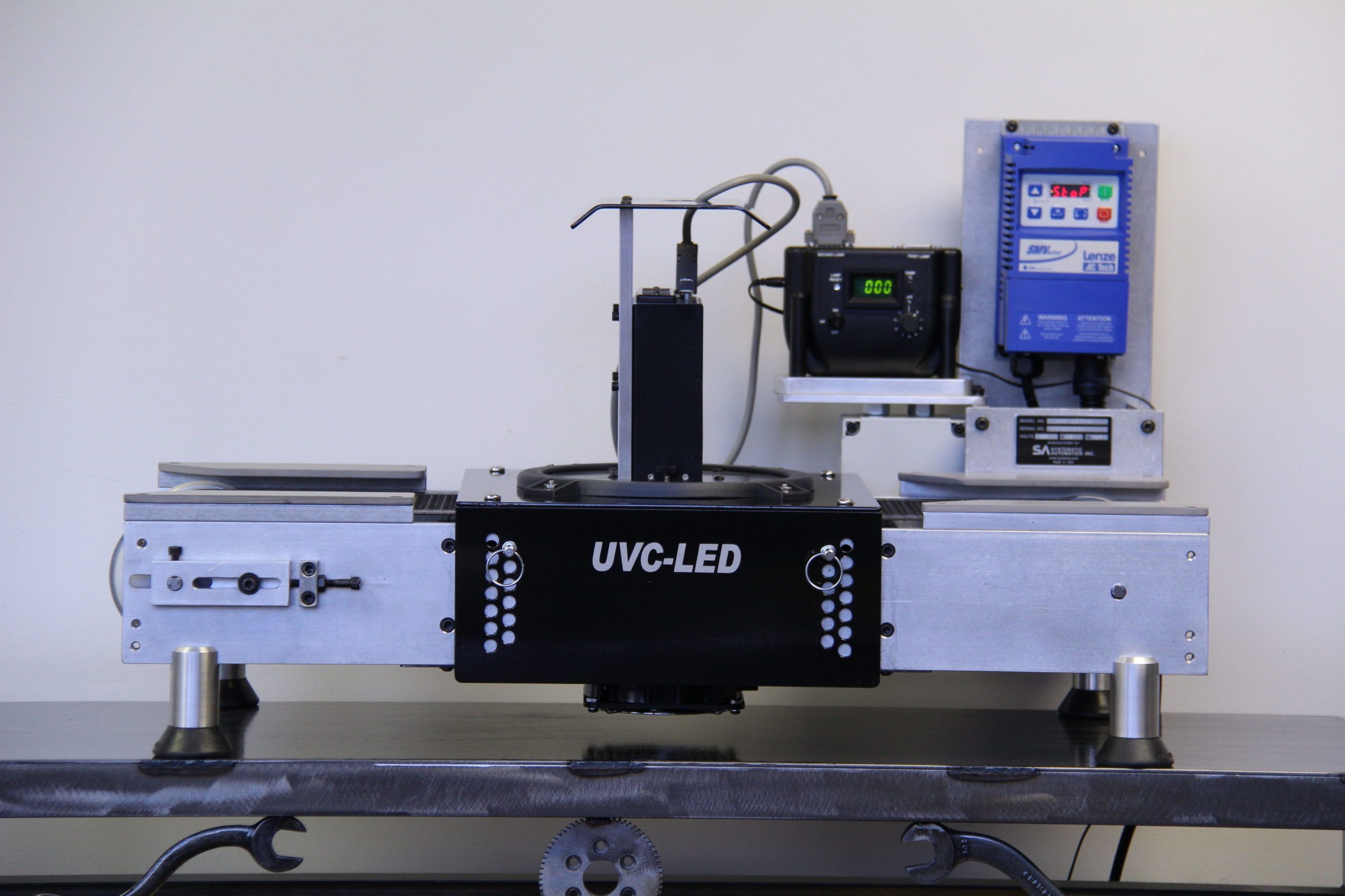

The Systematic Automation Ultra LED conveyor is designed for immediate use for reliable results for your cured products. The Ultra LED is used for curing coatings, adhesives and inks. It can feature any LED system of your choice, which will your ink and budget will play a large role in deciding. Inside and out, Systematic Automation’s conveyors are manufactured to withstand the most rigorous work environments. Systematic Automation’s Teflon coated conveyor belts are built to withstand continous industrial use.

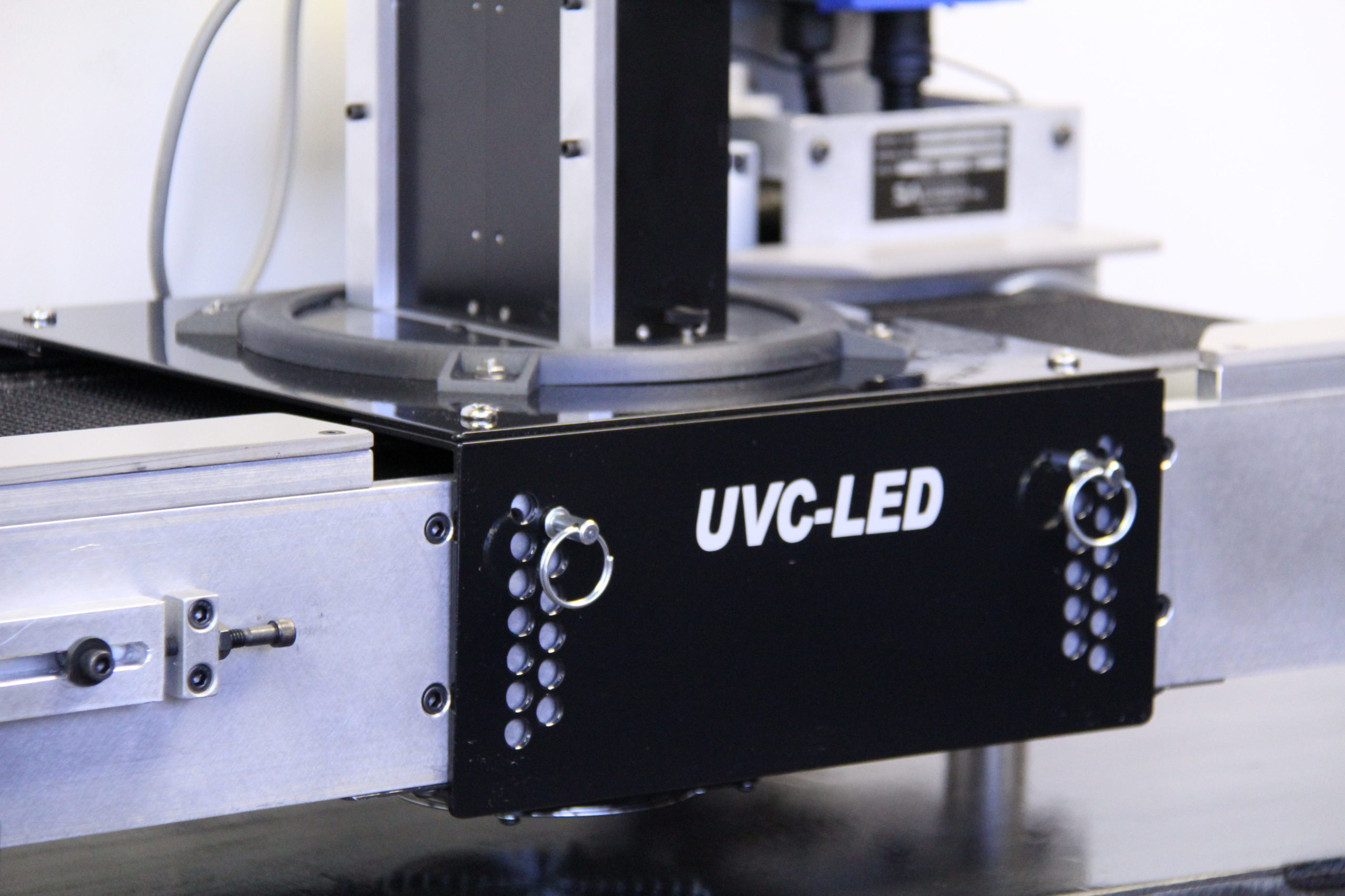

The Ultra LED conveyor features adjustable shroud and conveyor belt height, adjustable LED focal point, and intensity along with LED temperature readings. If you require features not listed, we will integrate them. All systems are manufactured in Farmington, CT. LED is extremely energy efficient when compared with conventional UV, emits significantly less light intensity and is ozone free (no venting from your work space is required). You will receive thousands of hours of more curing time than you would with conventional UV. The light being emitted is a specific wavelength as opposed to the spectrum with conventional UV systems which accounts for its high energy use and intense light.

LED Systems can be customized and stacked to your size preference.

Conveyor Features & Sizes

Features

- Modular LED input- you choose what system you want, we integrate.

- Digital display of conveyor speed, speed easily changed by up/down arrow keys.

- Programmable scale factor in different units.

- Standard conveyor speeds 1-50 or 1-10 FPM, specify your preference. Custom speeds available too.

- Relay output provided for interface to other equipment.

- Unique conveyor pulley design for perfect belt tracking.

- Adjustable legs for conveyor height position from 35.5″ (902 mm) to 42.5″ (1079 mm).

Sizes

- LED system size is custom to your preference for each conveyor size.

- 63″ long conveyor, 14″ wide belt.

- 135-1/2″ long conveyor, 25-3/4″ wide belt.

- 135-1/2″ long conveyor, 32-7/8″ wide belt.

- 135-1/2″ long conveyor, 37″ wide belt.

- 135-1/2″ long conveyor, 47″ wide belt.

- Larger sizes available.

Industries Served

- Ad Specialty

- Printing – Screen, Digital & Flexo

- Medical

- Industrial

- Electronics – Touch Panel, Mobile Phone, Etc..

- Adhesives

- Automotive

- Wood – Edge Coating & Roller Coating