Koozie Screen Printing Machine

- Koozie printing simplified.

- Approximately 3,600 prints per hour.

- Full 360 degree print area

- 8 station servo indexer.

- Automatic take off into dryer.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for? Feel free to browse by screen printing application.

- Koozie Printing

- Features

Koozie Printing

Automate Your Koozie Screen Printing Production

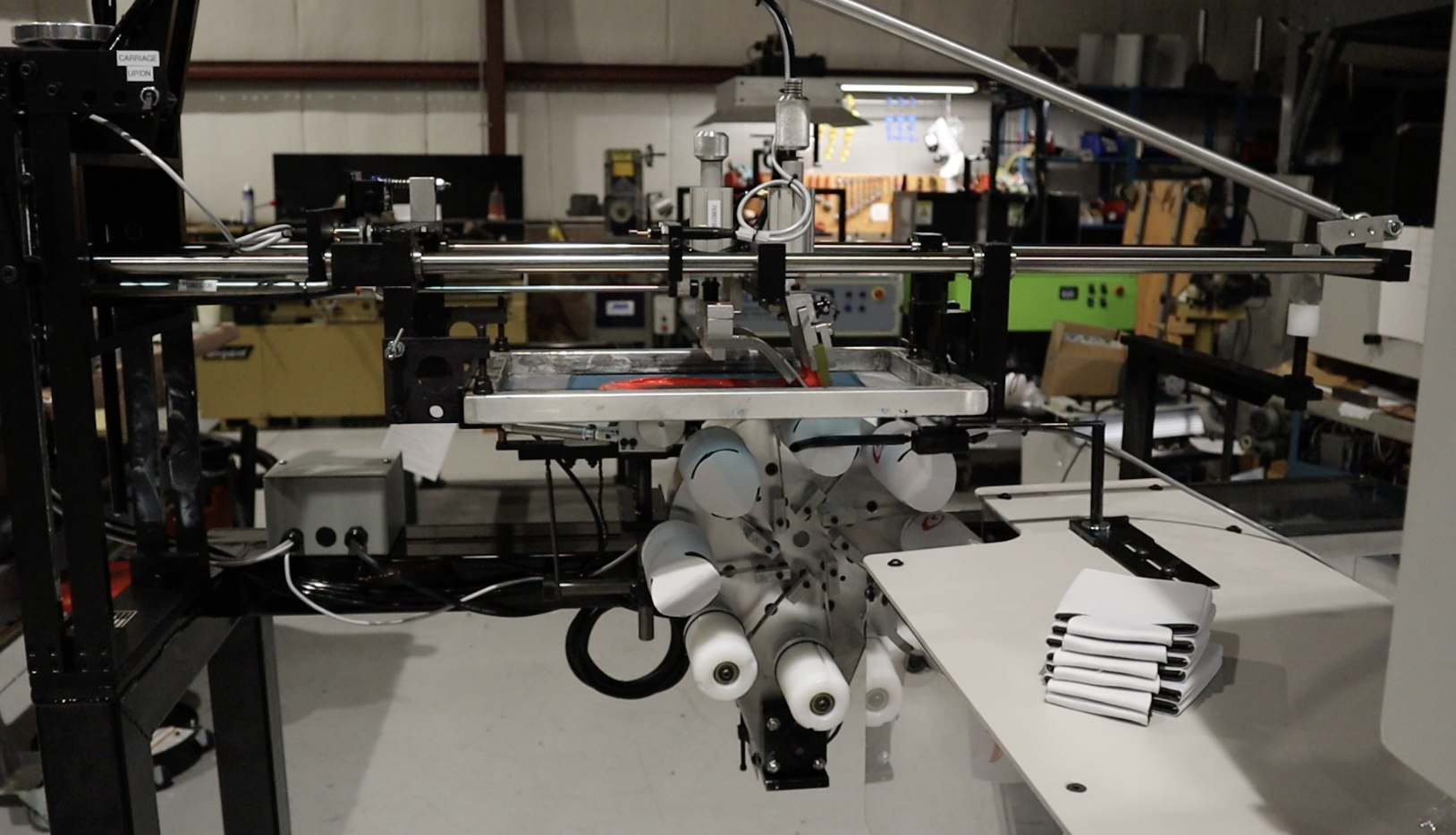

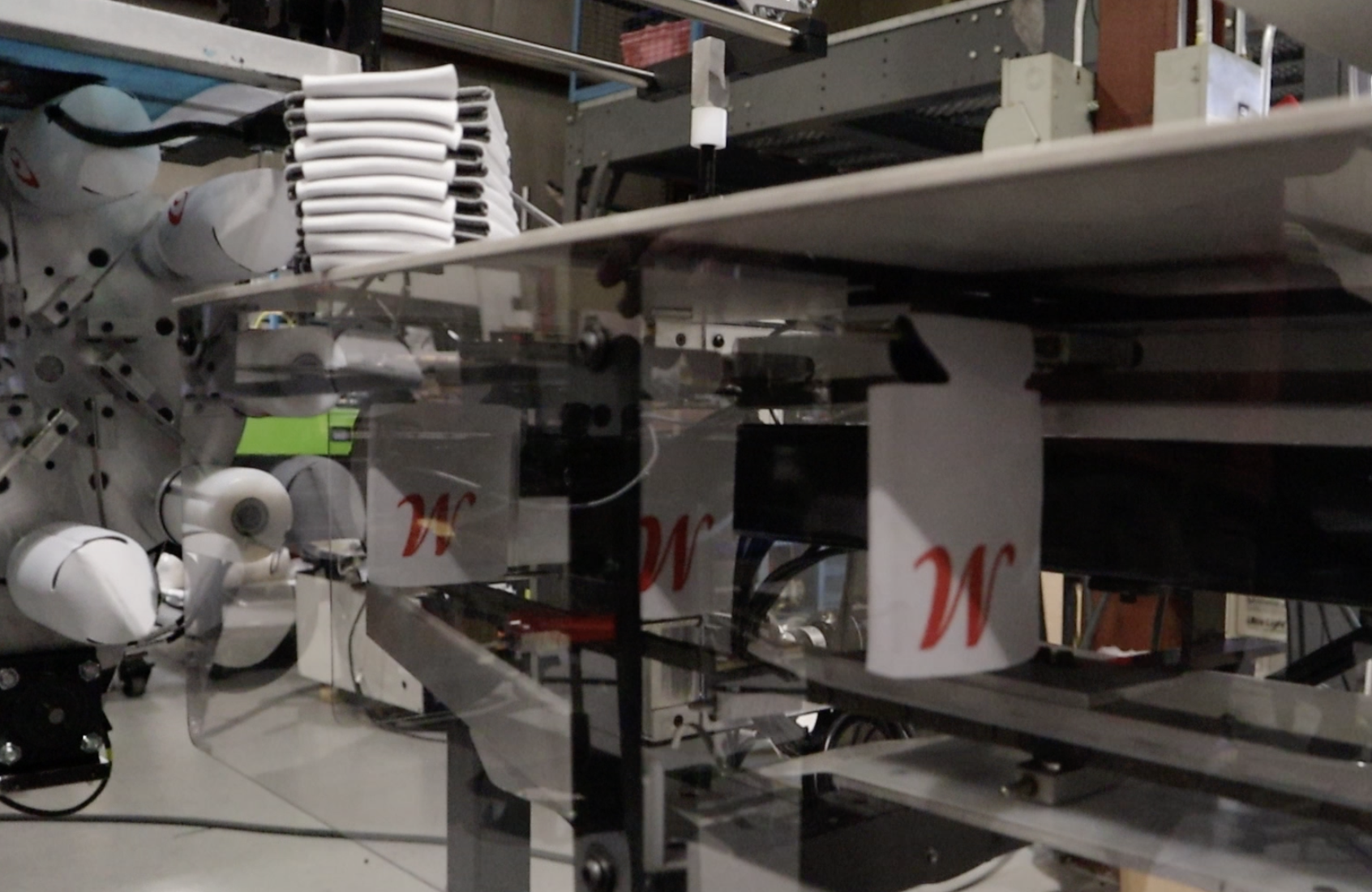

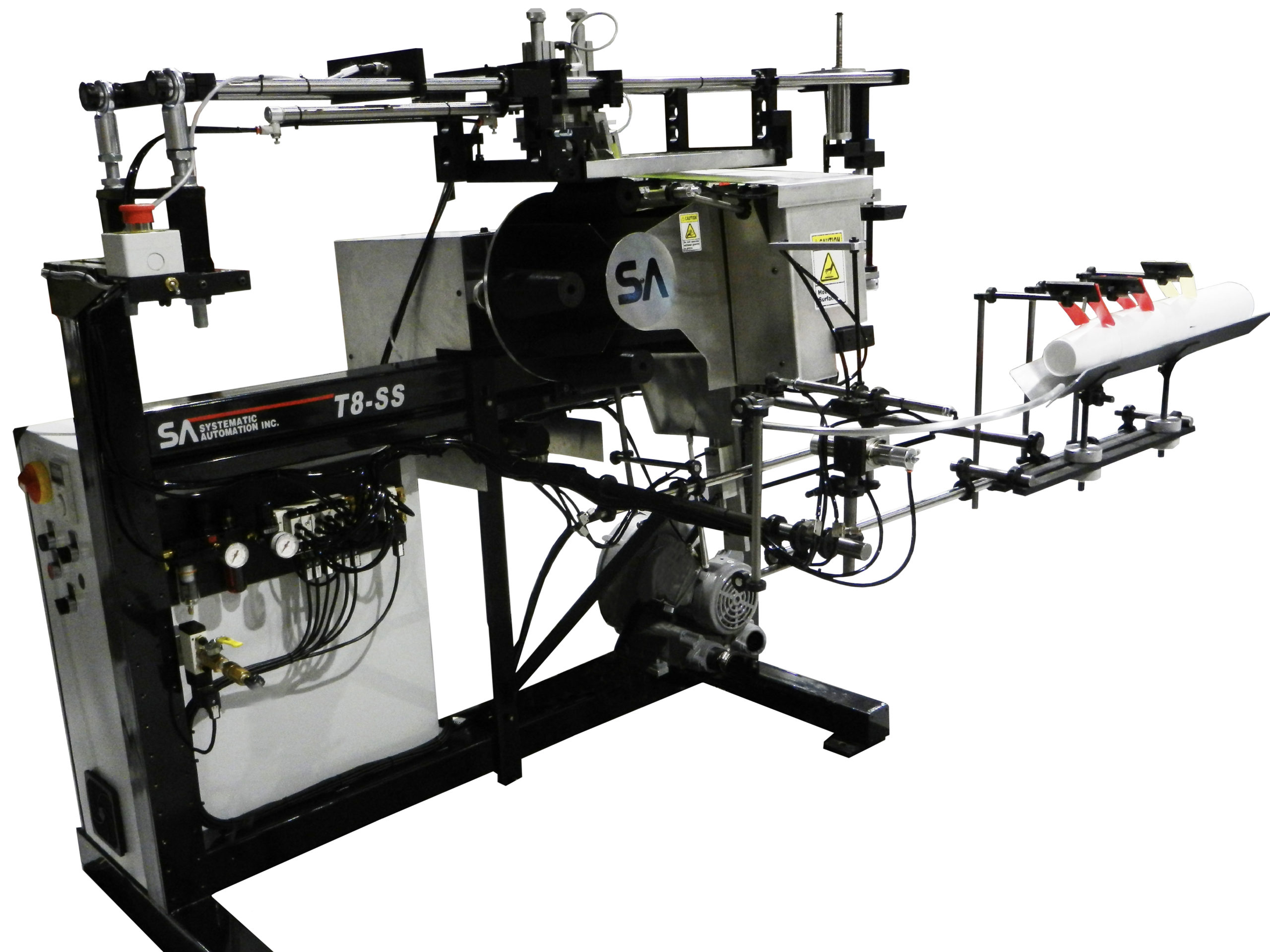

The brand name Koozie and term can cooler are interchangeable. For the purpose of describing the machine, we will use the term Koozie for the title of the machine. The Koozie Printer includes an eight station rotary indexer for high speed printing of collapsible koozies that are either foam or neoprene in material. Koozie printing occurs on both sides of the koozie in a single operation, which will cut the print time in half when compared to rotary or clamshell based systems.

The Koozie Printer includes a servo driven unloader, which automatically removes the koozies from the print area and then brings them through a super efficient and compact electric dryer. The dryer has been designed specifically for koozies making it the most energy efficient dryer available; your energy savings will be significant. Provide quality products with the industry standard for printing your koozies. Keep your beverage cold while spreading brand awareness.

Features

Screen Printing Koozie Features

- Precision machine tool quality and durability.

- Operator friendly controls.

- 8 station servo indexer is standard.

- Auto-take off into dryer.

- 100% air operation (safer for use near flammable solvents).

- Pneumatic systems cannot overload or burn out.

- Smooth, quiet operation.

- Hardened ground and polished shafts, top quality linear ball bearings rated at over 300 million cycles.

- Open design keeps ink vapors from collecting or being directed toward operator.

- Universal screen mount.

- Quick release squeegee assembly.

- Flood bar rises and falls alternately with squeegee.

- Carriage opens pneumatically for screen cleaning and set up.

- Precision hinged rear screen frame holder provides access to inside of screen and squeegee without affecting registration.

- A timer to shut off the heater if the conveyor has not been run for a designated time period.

- A sensor and electronic counter to count the can coolers as they fall from the dryer unloader.

- A smoke detector mounted on top of the dryer. The smoke detector will make an audible signal if smoke is detected and will automatically shut off the heater.

Standard Features

- Unloader to put can coolers onto dryer.

- Adjustable drag for mandrels.

- Servo-indexing hot air can cooler dryer for plastisol inks.

- Control Panel.

- Emergency stop.

- Adjustable operating speed.

- Adjustable print speed.

- Adjustable flood speed.

- Adjustable squeegee pressure with gauge and regulator.

- Single cycle/automatic cycle.

- Print-flood/flood-print switch.

- Carriage up/down.

- Variable indexer speed.

- Squeegee holder.

- Heavy-duty welded steel base with casters and tote bins.

- Stroke counter.

- Foot pedal cycle start.

Koozie Printer Options

- Laser pointer for registration.

- Automatic orientation of the mandrel.

- Servo driven indexer (US patent #5,784,932) replaces pneumatic indexer for printer.

- Automatic Ink Dispenser.

- Part present detect.