T8-SS Screen Printing Machine

- Integrated UV and take-off system.

- Simple, reliable, easy to service.

- Approximately 1,800 parts per hour.

- Harmonic acceleration and deceleration of rotary indexer.

- Optional integration of automatic loaders, pretreatment and more.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Product Description

Automate Your Screen Printing Process

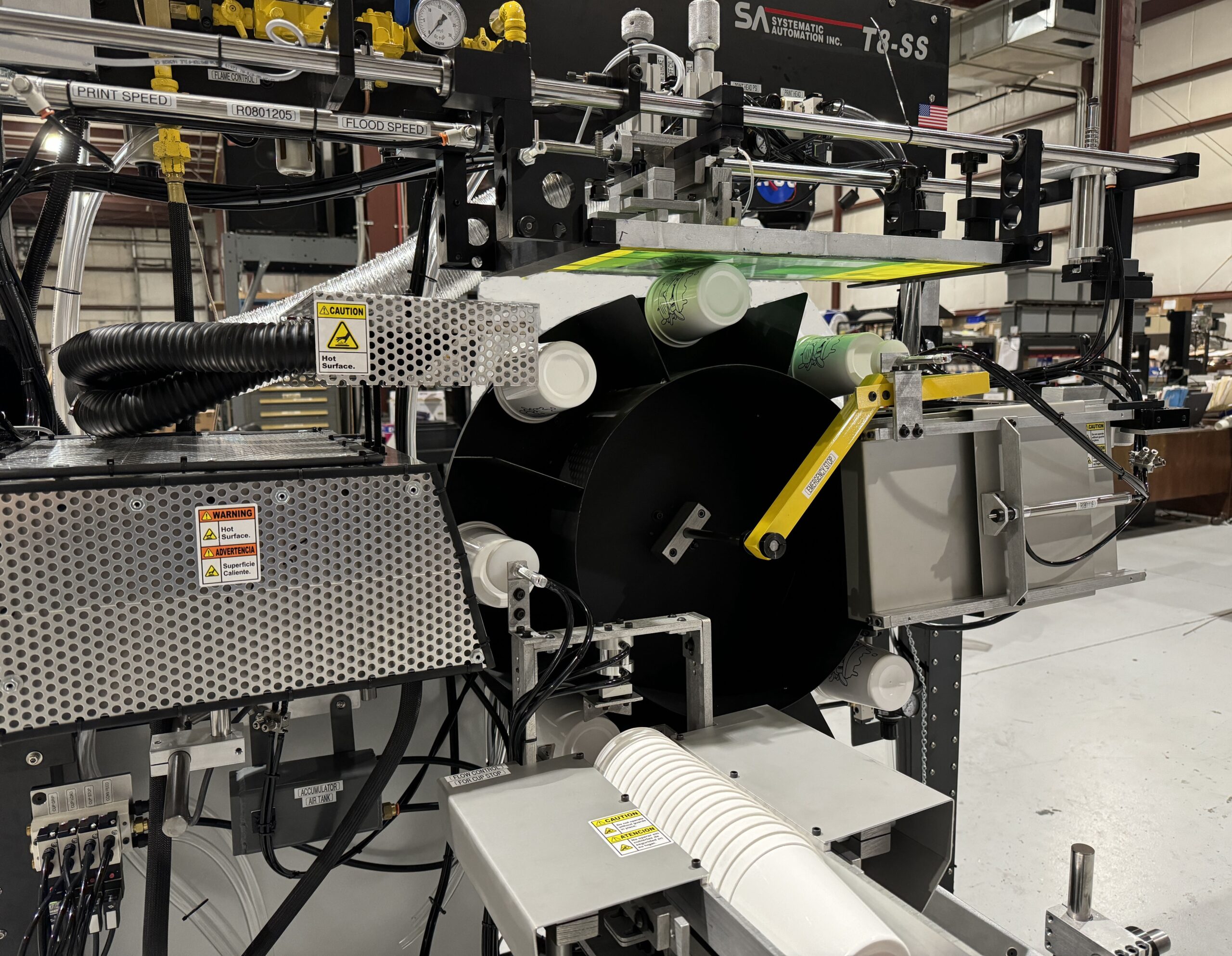

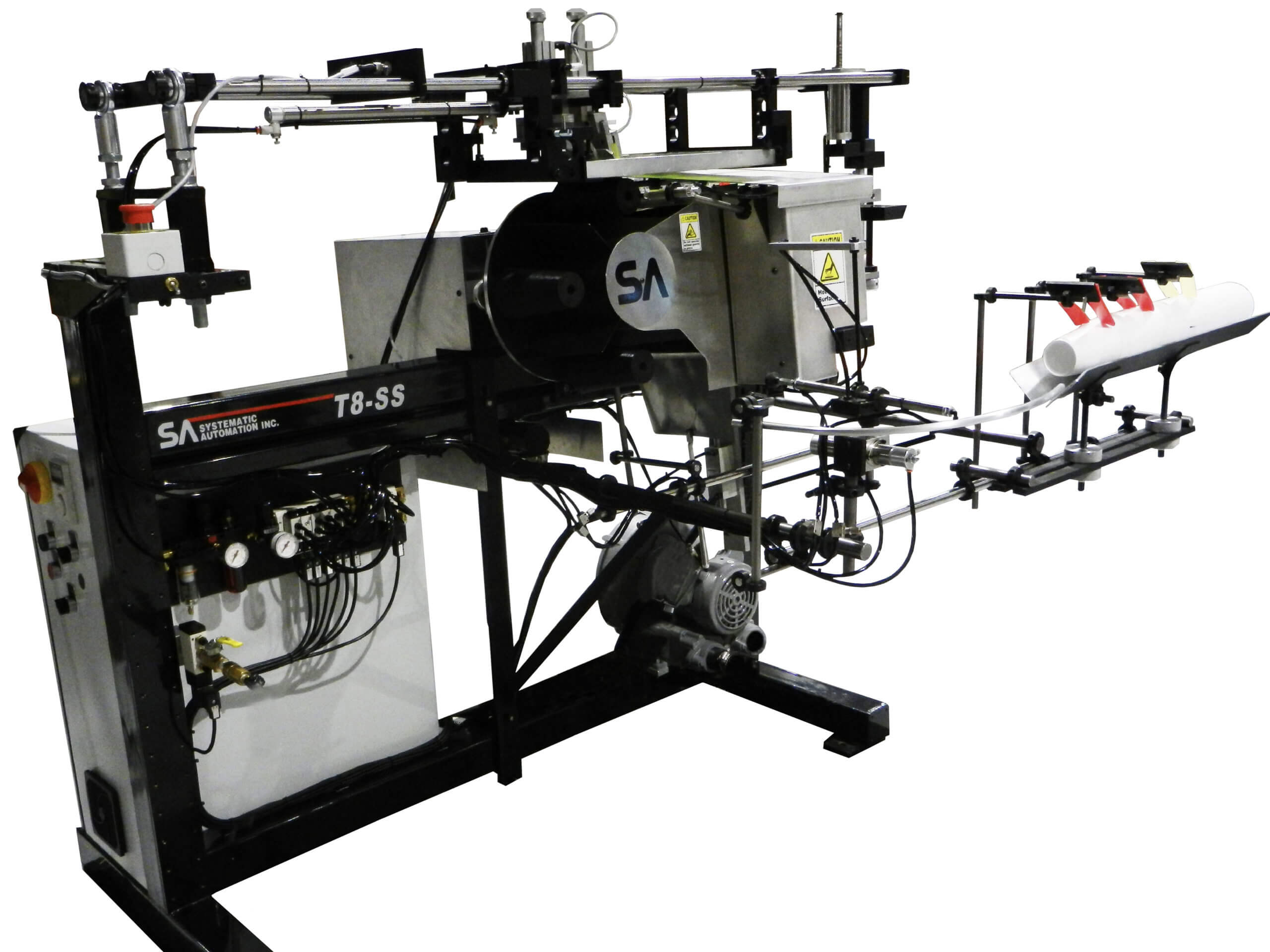

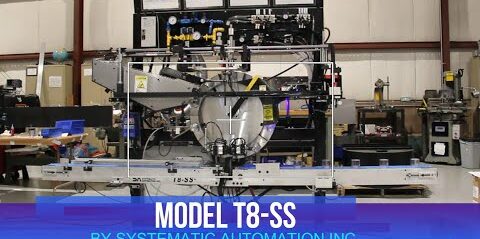

• Compact Profit Center: The Model T8-SS (U.S. Patent # 5,784,932) is designed for years of dependable service, allowing you to control production output, quality, and reduce labor costs with an easy-to-use and serviceable machine.

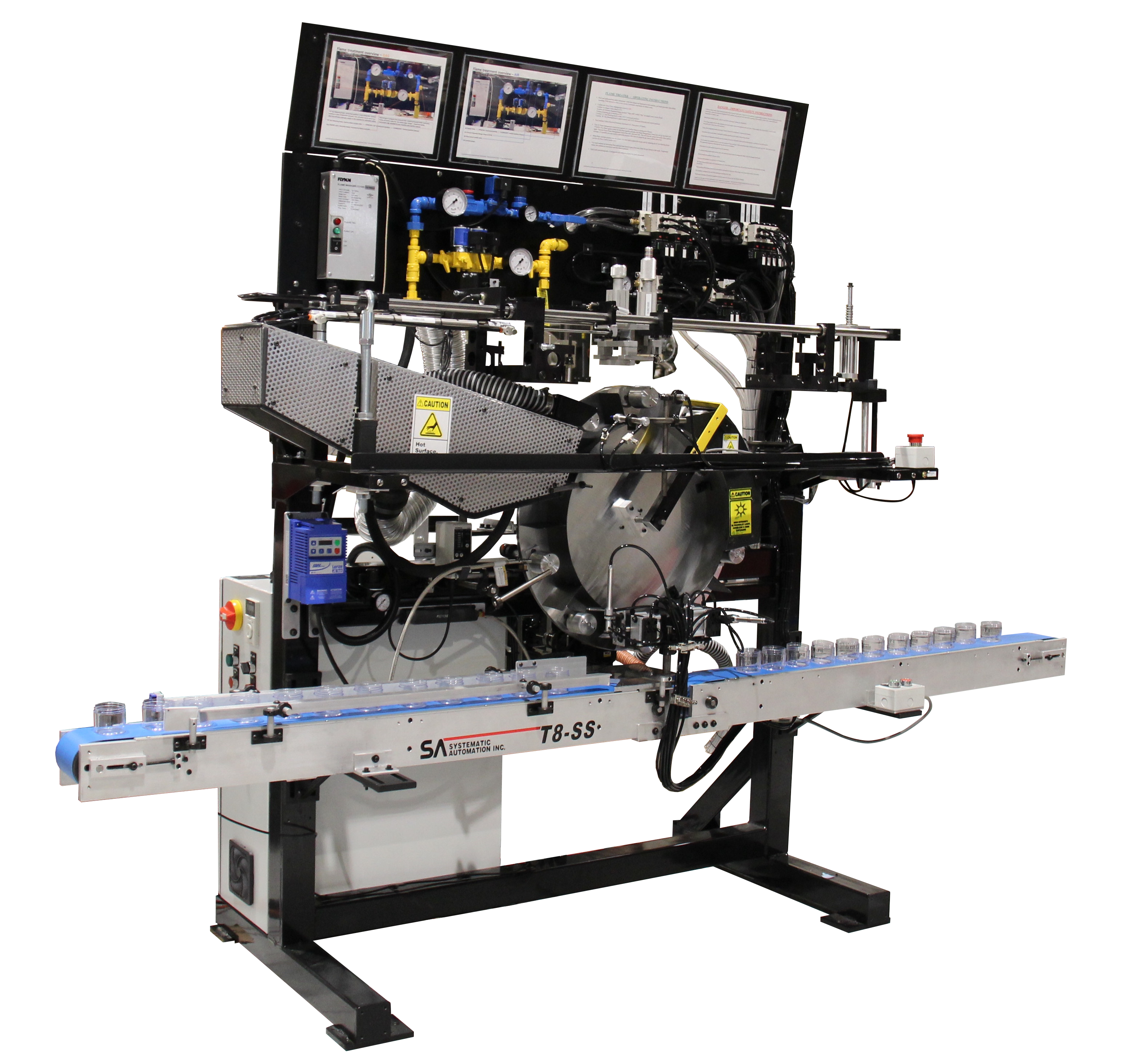

• Fully Automatic Features: Includes automatic loading (optional), pretreatment (optional), integrated UV curing, and unloading, streamlining your entire production process.

• High Accuracy and Speed: The servo-driven rotary indexer with 8 or 4 stations delivers unmatched accuracy and speed, capable of cycle speeds up to 1,800 parts per hour (depending on the application).

• Effortless Setup: Switching between products is easy, requiring only pre-determined settings rather than advanced skill, making it perfect for businesses with varying cup sizes.

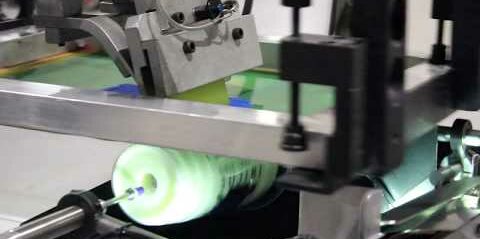

• Versatile Solution for Cups: Whether you’re printing small cups or stadium-size cups, the T8-SS delivers consistent, high-quality prints to meet your production demands.

Modular Automation Options

- LED module for UV curing in place of conventional UV lamp

- Conveyor loader system

- Automatic unloader onto conveyor

- Flame or FieroSil pretreatment

- Anti-static module attachment

- Mechanical registration for multicolor (submit product for evaluation)

- Visual inspection integration

- Integration with third party feeder equipment

Advanced Automation Options

Features

Engineering Features

- Unique modular design.

- 100% made in USA.

- Simple, reliable, easy to service.

- Machine tool quality and durability.

- Hardened, ground and polished shafts, top quality linear ball bearings rated at over 300 million cycles.

- Harmonic acceleration and deceleration of rotary indexer.

- Overload protection for operator safety.

- Quick release squeegee assembly.

- Flood bar rises and falls alternately with squeegee.

- Smooth, quiet operation.

- Carriage opens pneumatically for screen cleaning and set up.

- Electrical enclosure is hinged and swings open for easy access.

Standard Features

- Patented (U.S. patent #5,784,932) servo driven indexer.

- Product present detector.

- Ultra Light UV system.

- Ultra Light UV light shutters and guarding.

- Quick change over from one product size to the next.

- variable UV product rotation speed.

Options

- LED Integration in place of conventional UV.

- Pre-treatment.

- Multicolor pre-registration.

- Automatic ink dispenser.

Pretreatment

Your product surface may require pretreatment to promote ink adhesion. Products ordered in bulk may have oil contaminants or other residue as well as having poor surface tension, which can be remedied by flame pretreatment. Pretreatment integration is done by installing a burner on your machine that will provide flame to your entire surface area. If your product is cylindrical, it will spin 360 degrees, parallel with the burner and if it is flat, the flame system will move to cover your product area. Burners are made in house and to size. Pretreatment is done prior to printing your product.