Vacuum Tables

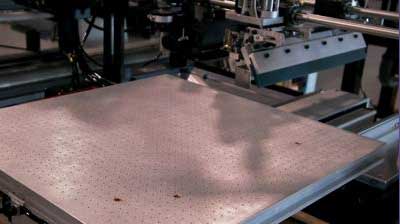

Screen Printing Vacuum Table Equals Winning Combination

Combining screen printing with vacuum table systems provides many benefits which greatly improve product quality and process efficiency. Screen printing machines which utilize vacuum systems realize greater product quality as substrates do not move during the printing processes for precision printing. This is true of many different products such as printing on small parts for…

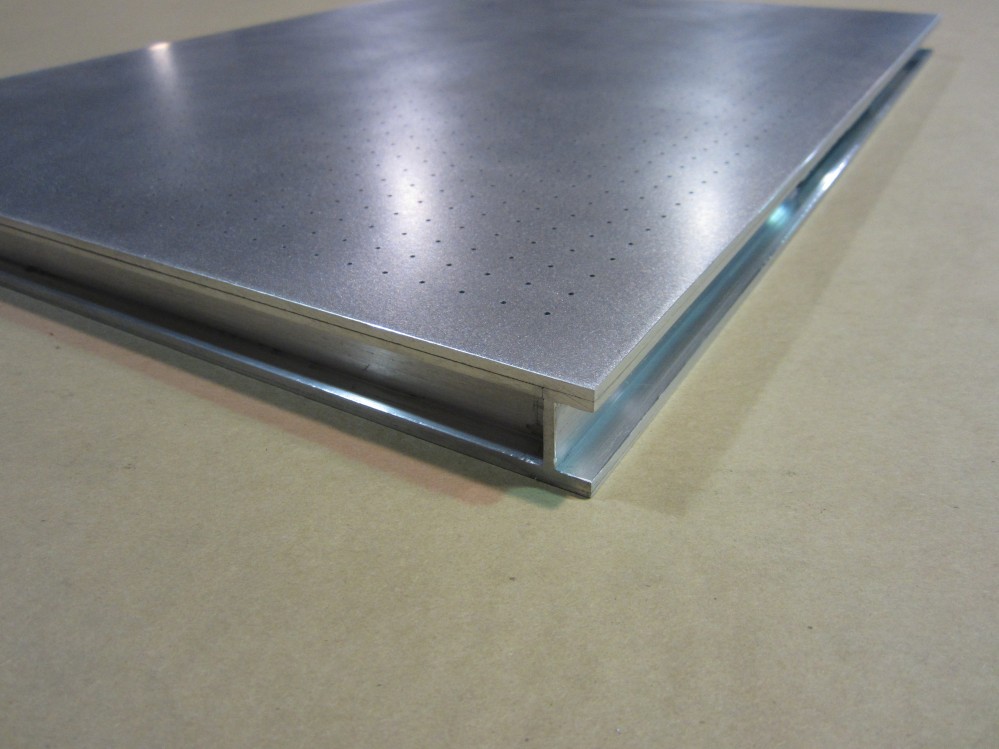

Read MoreVacuum Clamping Tables Designed to Your Application

Vacuum clamping tables are the preferred hold down method in many commercial and industrial processes. Vacuum tables offer many advantages over other hold down methods such as jigs, screws and adhesives. Utilizing controllable vacuum force to keep substrates securely in place during precision processes such as cutting or grinding provides quick changeovers, consistent flatness and…

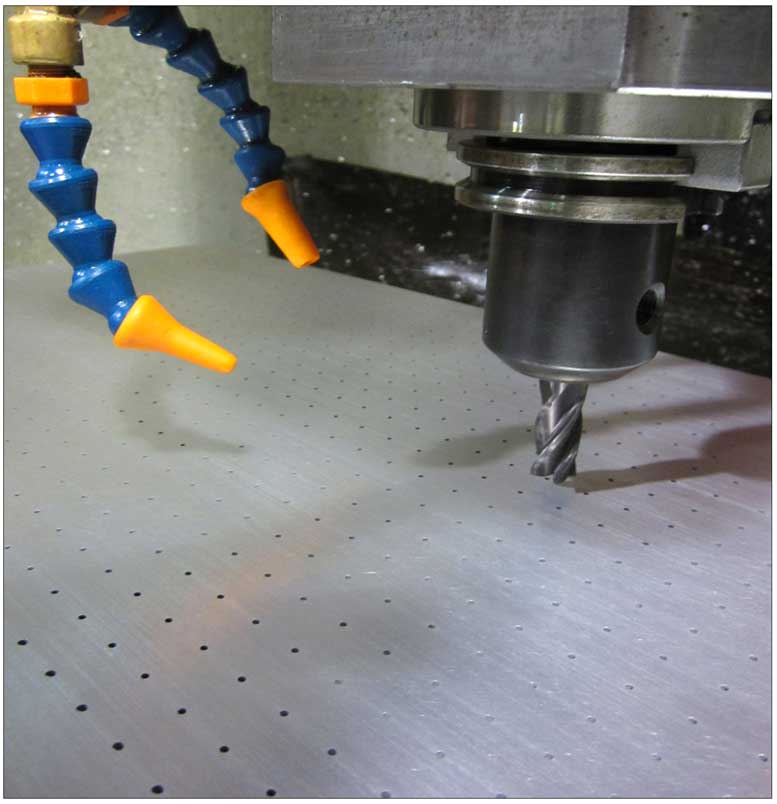

Read MoreWhy a CNC Vacuum Bed is the Best Hold Down Method

When choosing the best hold down method for your CNC application, it is important to evaluate the benefits of using a CNC vacuum bed. Vacuum systems provide hold down force during many processes, keeping various substrates and materials firmly in place during applications such as cutting and grinding. Critical applications which utilize computer numerically controlled…

Read MoreHow to Evaluate CNC Router Hold Down Methods

Choosing correct CNC router hold down methods is one of the most important factors which affects the quality and efficiency of any CNC router application. Computer numerically controlled (CNC) applications provide consistent and reliable operations, which is a vital component in quality processes. Supporting CNC router applications with equally consistent and reliable hold down methods will…

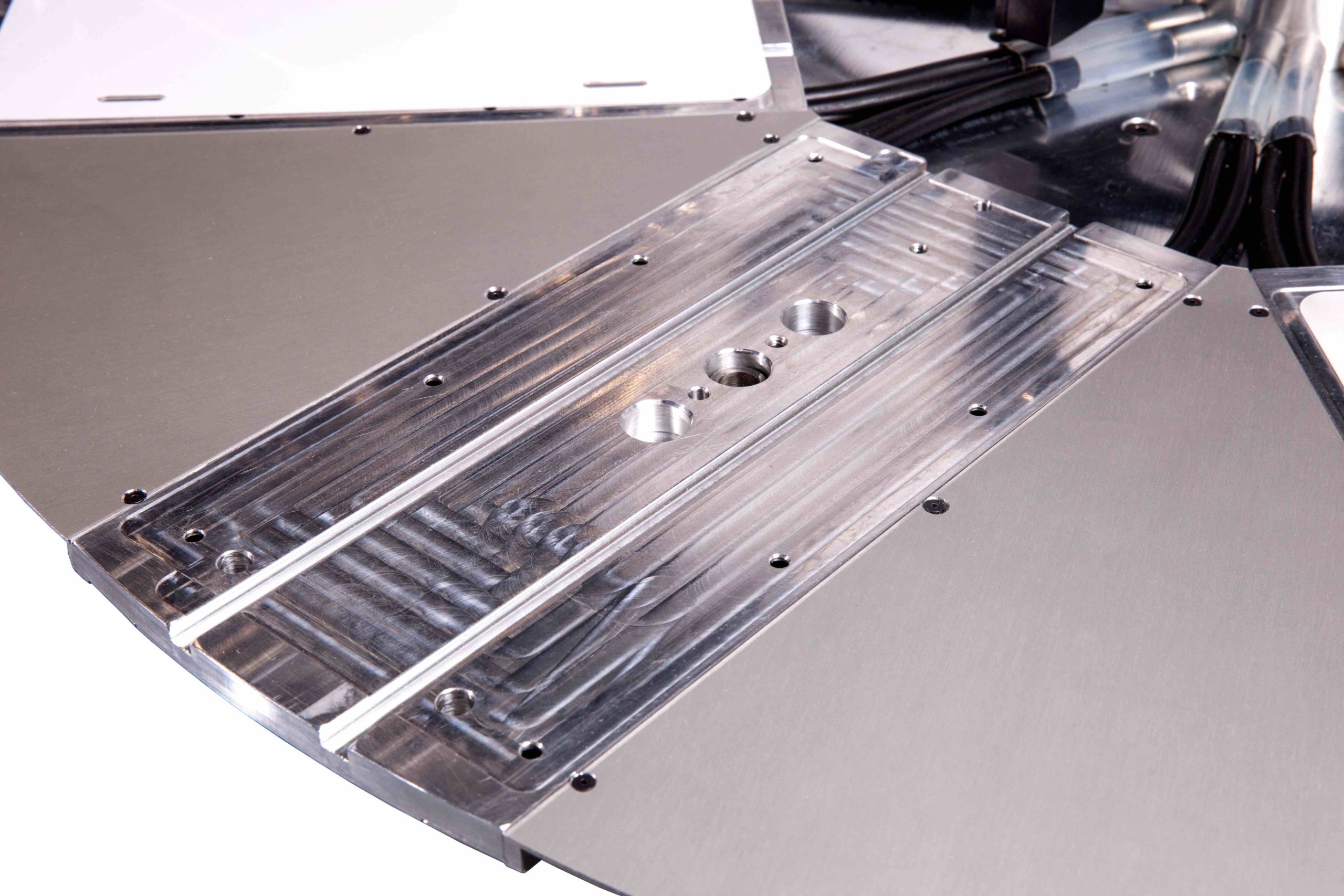

Read MoreUse the Right Vacuum Pump for Vacuum Table Processes

It is important to use the right vacuum pump for vacuum table processes, as the required vacuum force varies widely depending upon the size of the part and the application required. A vacuum pump is used with a vacuum table to hold down parts and various substrates during processes applications such as: CNC machining Cutting…

Read More