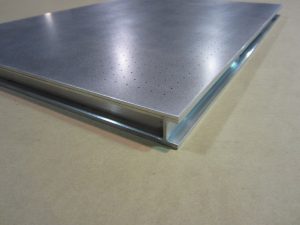

Vacuum table flange for clamping. C-channels can face inward.

Vacuum clamping tables are the preferred hold down method in many commercial and industrial processes. Vacuum tables offer many advantages over other hold down methods such as jigs, screws and adhesives. Utilizing controllable vacuum force to keep substrates securely in place during precision processes such as cutting or grinding provides quick changeovers, consistent flatness and precision accuracy.

Vacuum tables designed to your application provide maximum value to promote the most effective and cost-efficient operation. Utilizing the right type of vacuum pump with the right vacuum table design for your process will improve process and product quality. Vacuum tables are used to securely hold a wide variety of substrates such as plexiglass, paper products, wood products, steel, PVC, canvases, fabrics and many others.

Here is a short list of some applications in which vacuum clamping tables are proven to provide significant process improvement:

Assembly and Alignment – vacuum tables assist many assembly and alignment operations by holding materials flat and secure. Vacuum force is effective and efficient in hold materials such as thin layers of plastics perfectly flat without wrinkles, or for use in holding ceramics or glass products in perfect alignment. Attachments and guide tools assist with perfect alignment.

CNC Router Processes – vacuum tables are used in many computer numerically controlled applications to complement precision processes with consistent and reliable hold down force. Custom designed CNC vacuum tables can provide specific zones with control valves, and table surface options such as sacrificial layers to protect your tabletop during cutting processes.

Surface Grinding – vacuum tables have been assisting the manufacturing industry in surfing grinding processes for many years. Vacuum tables allow for quick changeover coupled with strong holding power with some tables providing over 50 pounds of lateral holding power without jeopardizing flatness for accuracy and grinding processes.

Plotter and Cutter – precision vacuum tables firmly hold products in place during many plotting and cutting processes with reliable hold down force to ensure accurate cutting. Sacrificial layers protect the tabletop surface. Vacuum tables assist plotter and cutter operations such as cutting fabrics and canvas which require a heavy duty vacuum pump.

Digital Flatbed Printing – vacuum clamping tables significantly improve flatbed inkjet printing processes by providing consistent flatness which is critical to the printed image quality. Any variations in flatness will cause poor image quality and distortion on any flatbed printer application. Vacuum tables are an important part of many digital flatbed inkjet printer applications.

Artwork and Photography Showcasing – vacuum tables are used to showcase photography and artwork, with reliable vertical hold to display beautiful pieces without the need for frames or glass. Experienced vacuum table manufacturers can provide custom designed tables in the shape and color of your choice.

Flexographic Printing – vacuum tables are used to assist the manufacturing of graphic rubber rolls which are used in flexography machines. Quality vacuum tables are required for this process to ensure precision flatness or image quality.

Thin Film Applicator – heated vacuum tables are beneficial in processes which make thin films of lacquer and other various liquids. Heated vacuum table systems assist many processes such as bonding, curing and debulking.

Engraving – vacuum clamping tables are used in many engraving applications to securely hold materials firmly in place for precise, accurate and beautiful engraving results. Your vacuum table manufacturing specialist will help you select the right type of vacuum pump for your process to provide optimum holding power for your substrate.

Systematic Automation Designs Vacuum Clamping Tables

Systematic Automation is a leading global supplier of vacuum clamping tables designed to improve applications across a broad range of industries. We offer a wide selection of standard sizes and options from 5” x 6” up to 72” by 144”, with custom sizes available. We provide a table with horizontal or vertical vacuum hold down force, custom designed vacuum zones, custom shapes or colors, and several engineering features to meet your specifications.

We are a valued supplier to many industrial applications, providing process improvement to aerospace, automotive, CNC applications and many others. All equipment is manufactured in our modern United States facility where we follow strict quality controls. Exceptional customer service ensures successful installation and operation of your vacuum table no matter your industry.

Systematic Automation designs engineers and manufacturers superior vacuum tables with quality components to meet demanding industrial requirements. We offer a wide selection of vacuum tables, screen printing machines, pre-and posttreatment equipment. Contact us to speak with an engineer and learn how our vacuum table solutions will improve your commercial or industrial application.