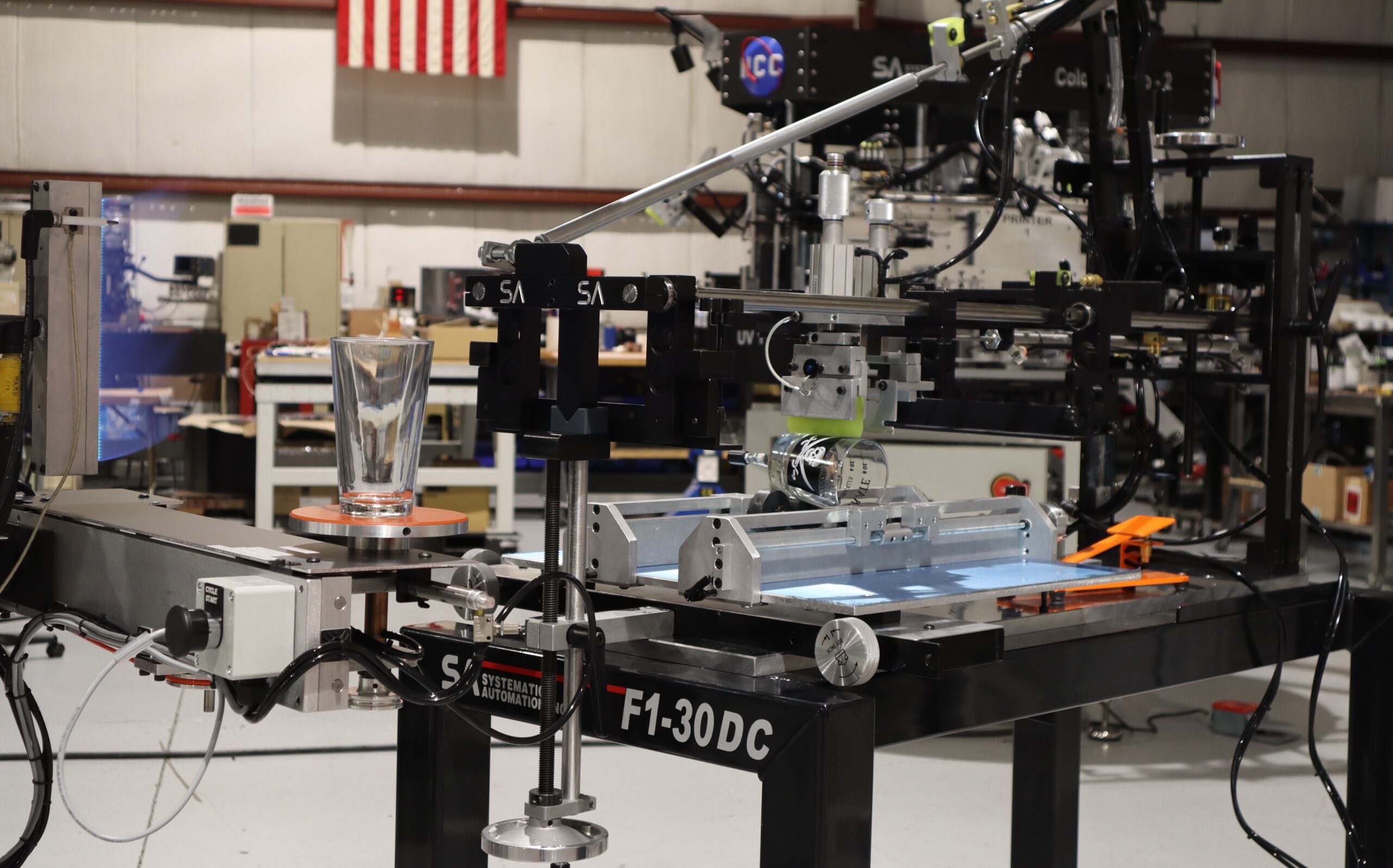

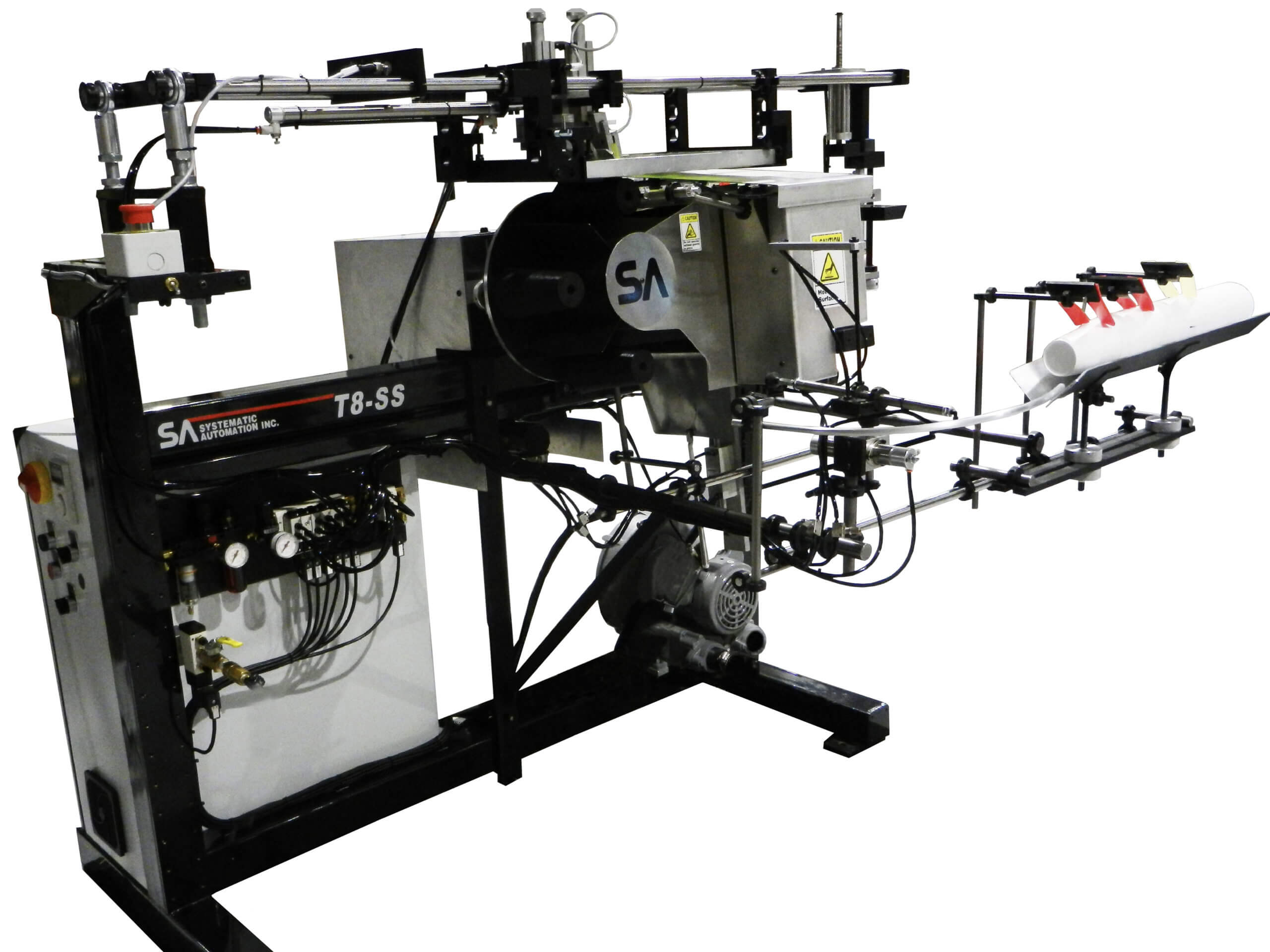

F1-DC Screen Printing Machine

- Ideal for cups, bottles, glassware and more for full 360 degree image coverage.

- Quick and easy changeover between products in seconds.

- Approximately 3,600 prints per hour (depending on product).

- 100% air operation – cannot overload or burn out, or become obsolete.

- Brilliantly simple, easy to operate and versatile.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Model F1-DC Description

The Right Solution For Every Industry

English Data Sheet | Spanish Data Sheet

• Run Your Business Smoothly: The Model F1-DC Precision Screen Printer is designed to meet the demands of your business—helping you complete jobs and make payroll.

• Proven Versatility: The Model F1 series is brilliantly simple, easy to operate, and adaptable for various product sizes and shapes.

• Dependable: The Model F1 is completely pneumatic with no electrical components to fail or go obsolete. The mechanical design allows you to take care of the system without relying on proprietary components.

• Professional Expertise: Each F1 printer comes with access to our dedicated team’s expertise, helping you select the right options from our vast library of hundreds of standard attachments and provide immediate technical support.

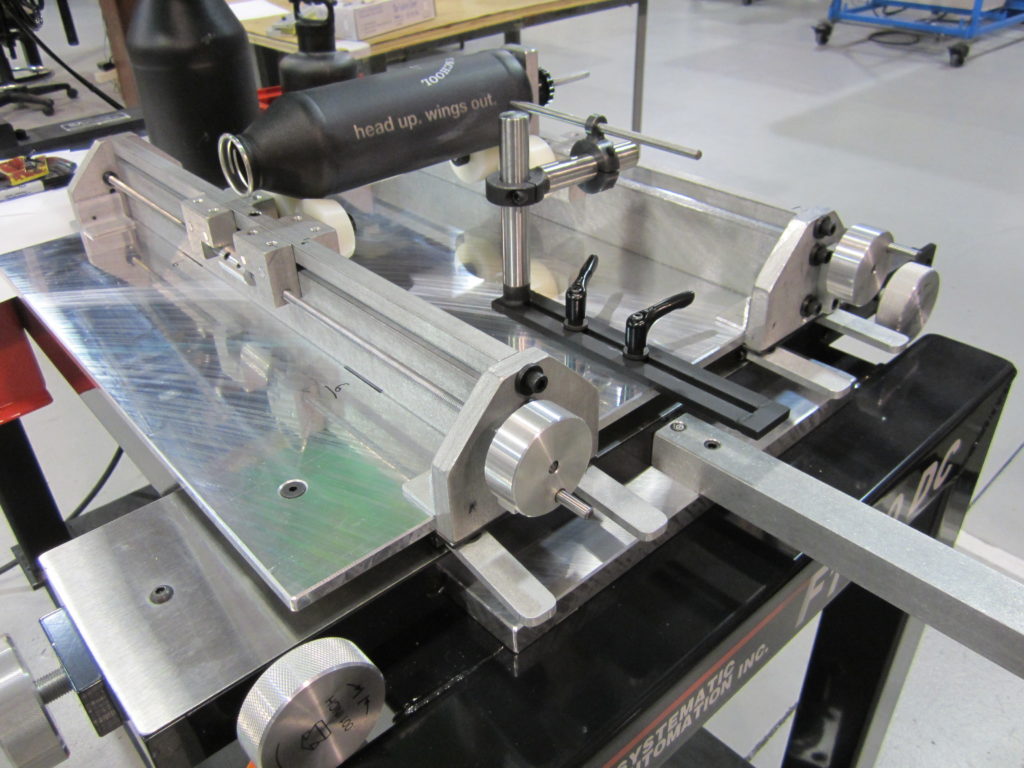

• Quick Changeover System: Systematic Automation pioneered the quick change dedicated tooling system, allowing operators to switch between products in seconds without adjustments to screen height, squeegee centerline, or image alignment—reducing the need for skilled labor.

• Any Production Volume: Ideal for both short runs and high volume production, Systematic Automation’s semi-automatic screen printing machines deliver efficient and consistent results for both silk screen technicians and shop managers.

About The Model F1-DC

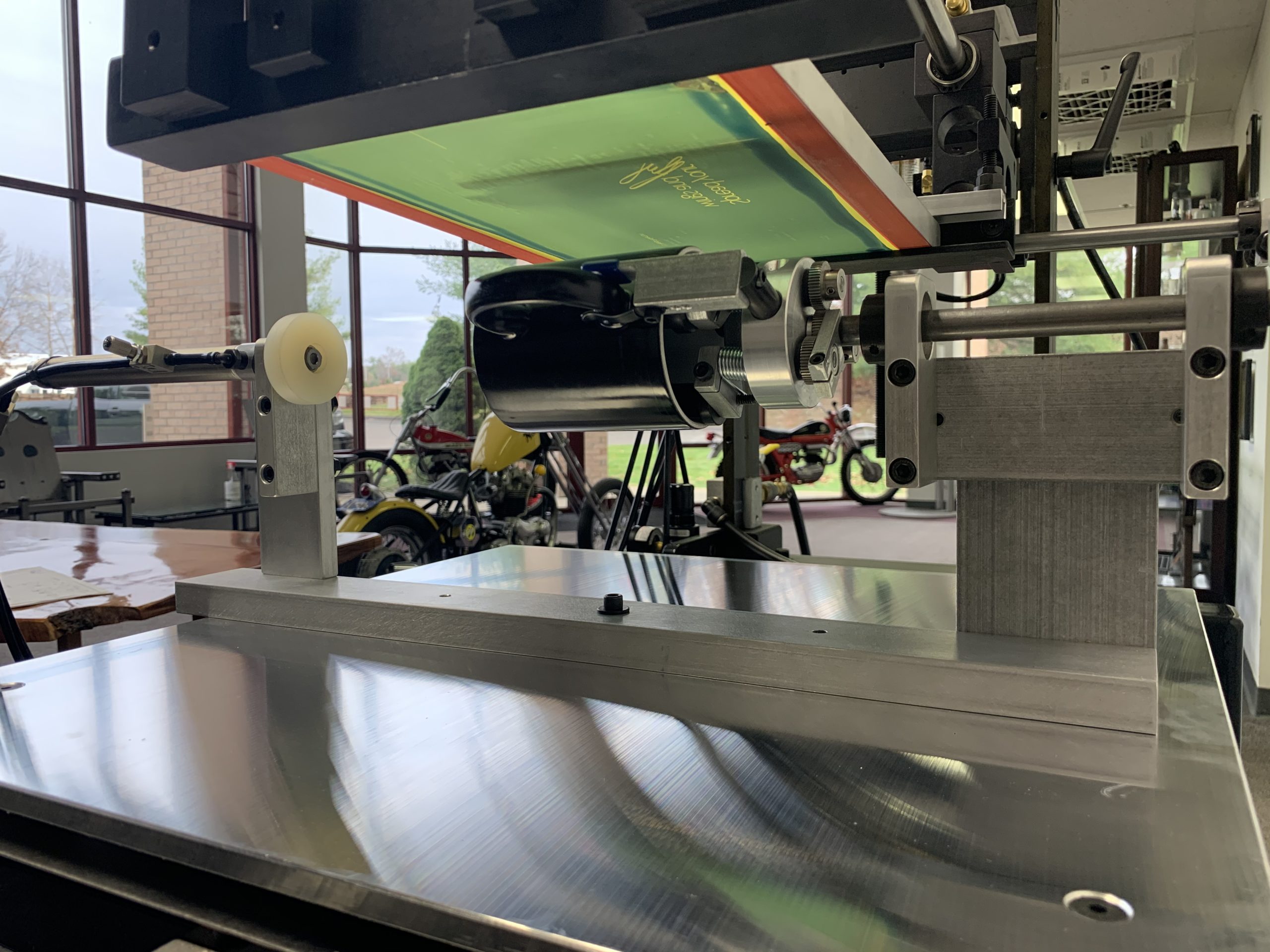

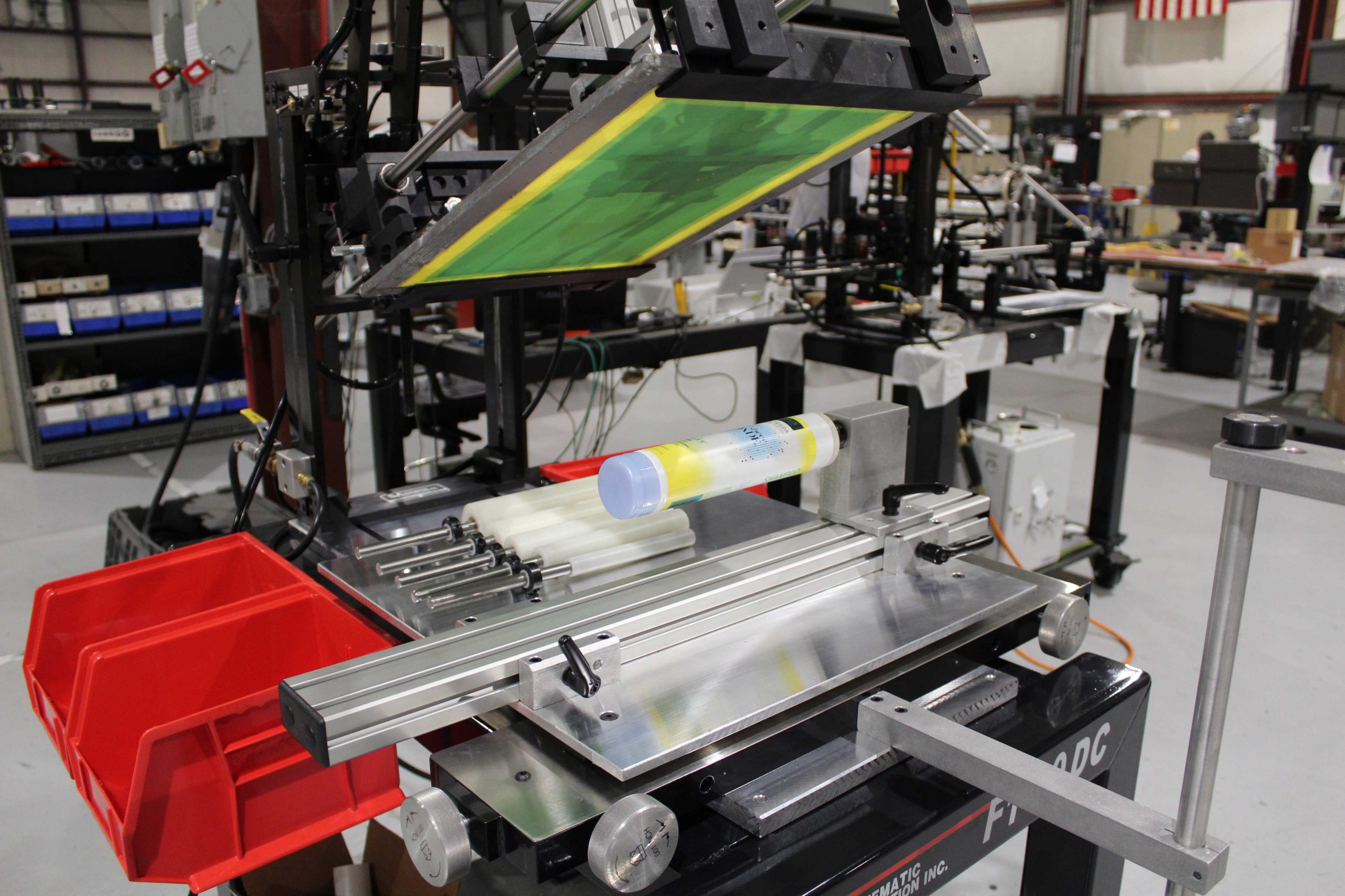

Printing With The Model F1-DC

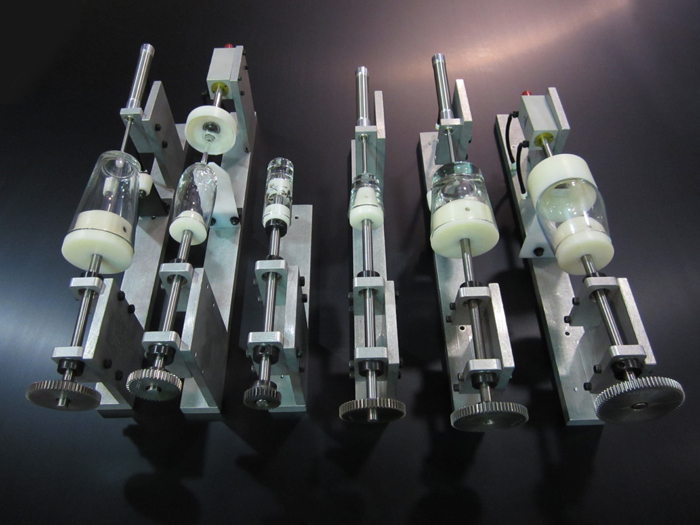

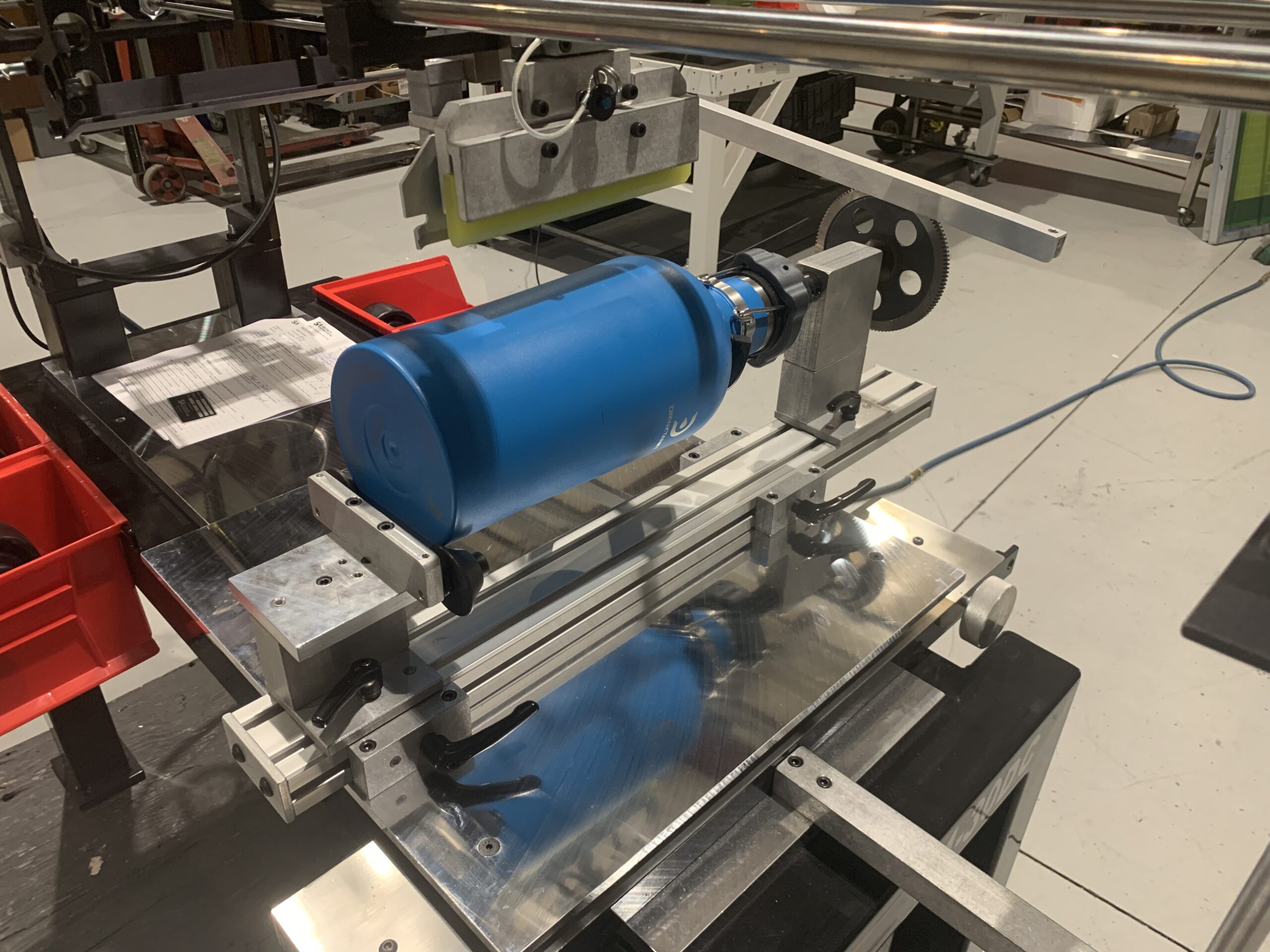

Product Tooling Available

How your product will be held during the print cycle, a necessary component for screen printing.

Universal | Dedicated

Why Choose the Model F1-DC

The Model F1-DC offers you versatility to print any cylindrical product. From a shot glass to a growler, you can print it all. Changeover between products will take you less than a minute. No skilled labor needed. Tooling can be made to suit your business needs. For example, if your product line is constantly changing, our universal wareholder tooling is adjustable for a wide variety of different shapes and sizes.

Configuration Example: Model F1-DC Configured for Pre-Assembled Lanyards

Screen printing is both an art and a science. Whether you’re just starting or looking to refine your skills, we’ve got you covered. Learn the essentials, avoid common mistakes, and discover the tools professionals trust to create stunning prints every time.

Features

Screen Printing Features

- Capability to print any cylindrical product.

- Precision system allows for multicolor printing.

- Quick and easy product changeover in seconds.

- Simple design allows for unskilled labor.

- Approximate throughput of 800 parts per hour (depending on article).

- Machine tool quality and durability.

- Aluminum tooling plate base ground flat within +/- .001” (.025 mm).

- Hardened ground and polished shafts with linear ball bearings rated at over 300 million cycles.

- 100% air operation.

- Pneumatic system cannot overload or burn out, or become obsolete.

- Universal screen mounting.

- Hinged rear screen frame holder to provide quick access to screen, squeegee and flood bar.

- Quick release squeegee holder and flood bar assembly.

- Smooth, quiet operation.

Standard Features

- X & Y micro adjust screen frame holder.

- Variable squeegee speed.

- Variable flood bar speed.

- Flood bar.

- Foot pedal cycle start.

- Adjustable print stroke/print flood length.

- Print/flood cycle – machine “waits” in flood position.

- Overhead carriage screen lift switch.

- Heavy-duty welded steel base with casters and tote bins.

Options

- Quick-changeover tooling.

- Adjustable squeegee pressure with gauge and regulator.

- Stroke counter.

- Multicolor registration system.

- Adjustable squeegee angle.

- Flood/print cycle replaces standard print/flood cycle.

- Inflation system.

- Adjustable universal ware holder.

- Screen Tension Meter.

- Automatic Ink Dispenser.

- Dedicated Tooling.

- Universal Wareholding