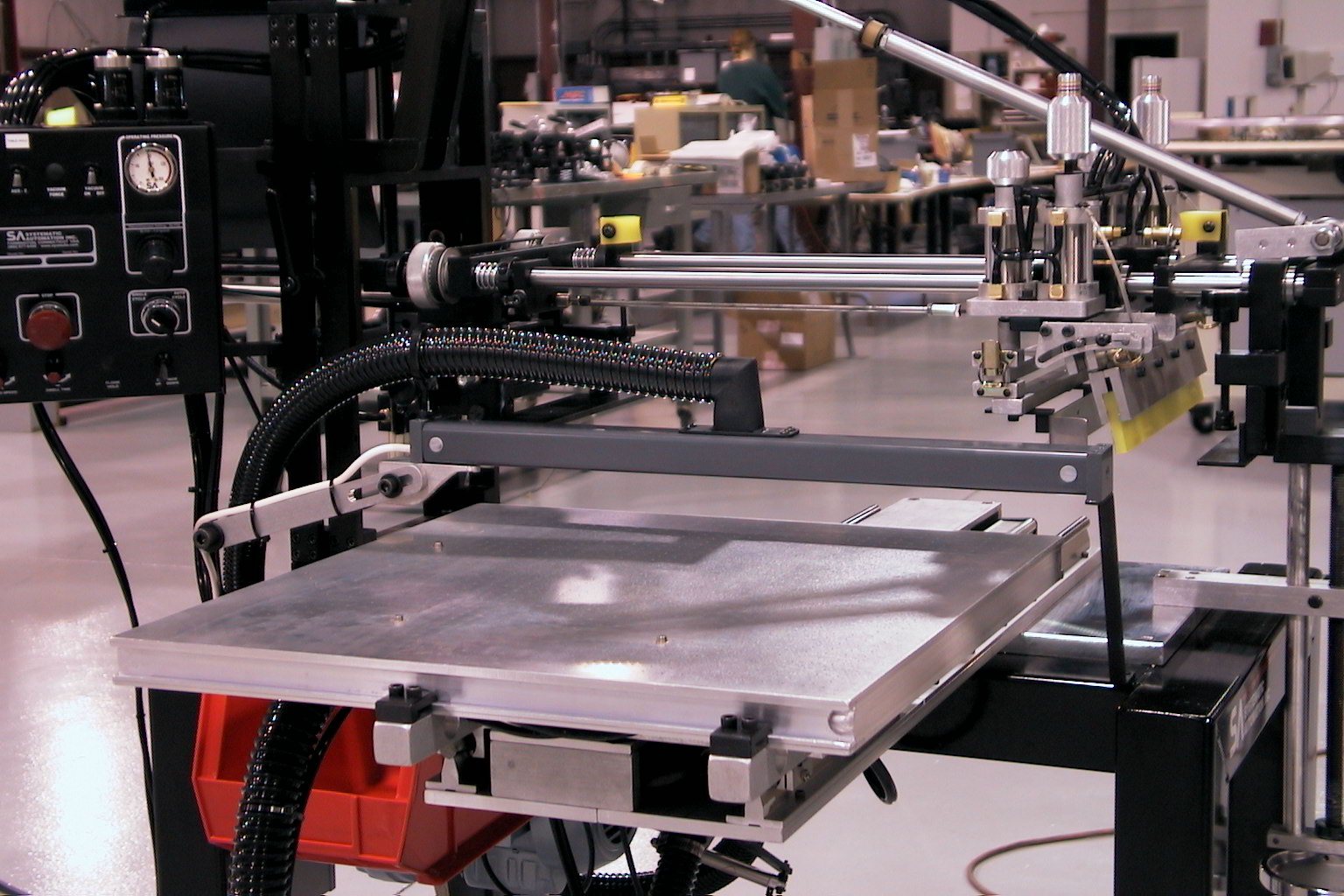

Sliding Table Series Screen Printer

- Ideal for 3D products, plates, panels and more.

- Top quality linear ball bearings rated at over 300 million cycles.

- Pneumatic system cannot overload or burn out, or become obsolete.

- Aluminum tooling plate base ground flat within +/- .001” (.025 mm).

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Product Description

Precision Printing with Full Accessibility

English Data Sheet | Spanish Data Sheet

• Enhanced Loading & Unloading: Full access to the table for easy product handling, outperforming “clam shell” presses in flexibility.

• Customizable Options: Sliding table design allows seamless integration of features like tacky rollers for pre-print particle removal to ensure top-quality images.

• Precision & Control: Options include automatic retracting pins, three precision dial indicators (X, Y, and angular adjustments), and dual print heads for consistent squeegee pressure on images 16” or wider.

• Advanced Functionality: Add pneumatic screen clamps, anti-static devices, tacky rollers, and automatic ink dispensers for optimal setup.

• Versatile Vacuum Table: Secure product hold-down with optional interchangeable fixtures and pop-up pins for easy take-off.

• Large Format Capability: The ST series can be customized for large products, accommodating sizes up to 48” x 48” and beyond.

Choose the Sliding Table Screen Printer for high-quality, accessible, and customizable printing—built to meet a range of production demands with ease.

Features

Engineering Features

- Machine tool quality and durability.

- Stainless steel air cylinders.

- 100% made in USA.

- Hardened, ground, and polished shafts with linear ball bearings rated at over 300 million cycles.

- 100% air operation.

- Pneumatic system cannot overload or burn out, or become obsolete.

- Variable print stroke length.

- Universal screen mounting.

- Quick release squeegee holder and flood bar assembly.

- Aluminum tooling plate base ground flat within +/- .001” (.025 mm).

- Hinged rear screen frame holder to provide quick access to screen, squeegee and flood bar.

- Smooth, quiet operation.

- Sliding table moves with minimal force for operator safety.

Standard Features

- X, Y, and angular micro adjust table.

- Heavy-duty welded steel base with casters and tote bins.

- Removable storage bins attached to base.

- Foot pedal cycle start.

- Squeegee holder.

- Flood bar.

- Pneumatic control panel.

- Variable print and flood bar speed.

- Adjustable print stroke length.

- Operating pressure adjustment with gauge.

- Print/flood cycle – machine “waits” in flood position.

- Air shut-off switch.

- Screen frame micro adjust.

Typical Applications

- Plastic cards

- Metal or plastic sheets

- Membrane switches

- Plaques

- Luggage tags

- Panels

- Circuit boards

- Nameplates

- Decals

- Glass and ceramics