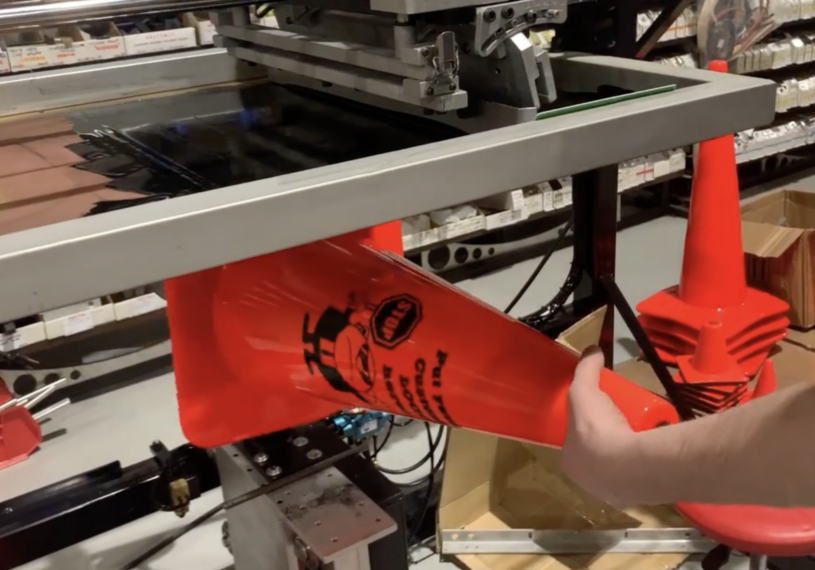

HLT Screen Printing Machine | Flat & Cylindrical Products

- Ideal for rulers, plaques, panels, 3D products and more.

- Table features independently micro-adjustable X, Y and angular movements.

- 100% pneumatic operation that cannot overload or burnout.

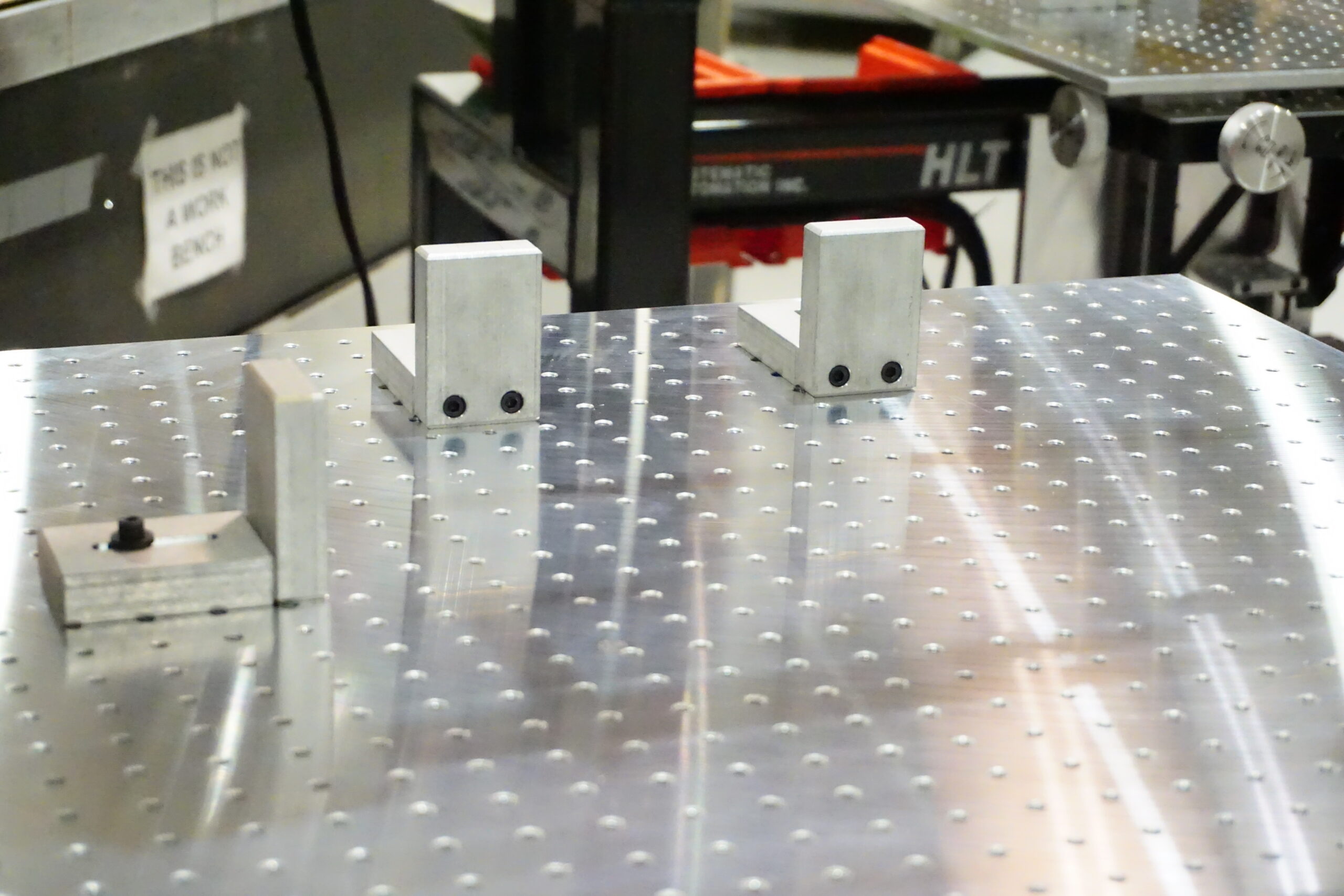

- Aluminum tooling plate base ground flat within +/- .001” (.025 mm).

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Product Description

Precision Harmonic Lift Printing

English Data Sheet | Spanish Data Sheet

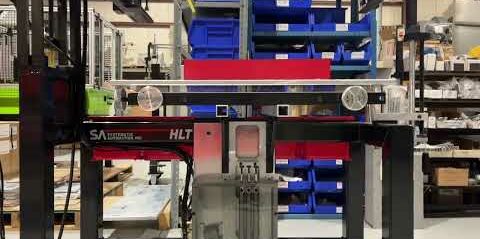

• Smooth, Fast, Vibration-Free Operation: At the core of the HLT is its Harmonic Lift Table, delivering smooth, fast, and vibration-free performance for precise, high-quality prints.

• Large Print Area: The HLT offers a best-in-class print with a maximum print area of 24” x 60”, ideal for large-scale printing.

• Micro-Adjustable Tooling: The micro-adjustable tooling plate adapts to X, Y, and angular axes, ensuring perfect registration even at high speeds for maximum productivity.

• Reduced Printing Flaws: By lifting the product to the screen (which remains stationary), the HLT reduces dust-related printing flaws, ensuring cleaner, more reliable prints.

• Durable and Long-Lasting: Built with linear bearings rated for over 300 million cycles, the HLT is designed for years of trouble-free service under heavy production.

• Versatile Applications: The HLT adapts to various substrates and shapes, including thick, thin, cylindrical, flat, tapered, and oval products.

Features

Engineering Features

- Machine tool quality and durability.

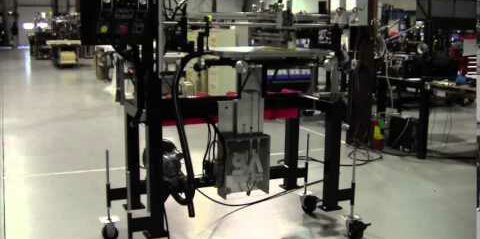

- Capability to print flat & cylindrical products.

- Stainless steel air cylinders.

- Hardened, ground, and polished shafts with linear ball bearings rated at over 300 million cycles.

- Screen stays stationary – substrate is lifted to screen.

- Independent micro-adjustable squeegee and floodbar height.

- Table features independently micro-adjustable X, Y and angular movements.

- 100% pneumatic operation that cannot overload or burnout.

- Aluminum tooling plate base ground flat within +/- .001” (.025 mm).

- 100% made in USA.

- Quick changeover from flat to cylindrical, tapered or ovals products.

- Flood bar rises and falls alternately with squeegee.

- Hinged rear screen frame holder to provide quick access to screen image area, squeegee and flood bar.

- Smooth, quiet operation.

Standard Features

- Pneumatic control panel.

- Emergency stop.

- Harmonic lifting table with 8′′ movement upward to screen.

- X, Y, and angular micro adjust table.

- Foot pedal cycle start.

- Heavy-duty welded steel base with casters and tote bins.

- Squeegee holder.

- Flood bar.

- Independent squeegee/flood bar height adjustment.

Options

- Vacuum table. Anodized top surface available.

- Quiet, regenerative continuous duty vacuum pump.

- Dual print head for precise squeegee pressure for images 16” (406 mm) or wider.

- Capability for printing cylindrical objects.

- Cylindrical printing attachments including inflation device for soft walled plastic bottles.

- Rack and gear drive for cylindrical printing.

- Adjustable squeegee angle.

- Adjustable squeegee pressure with gauge and regulator.

- Wide range of standard tooling fixtures developed for plastic, ceramic and glass products.

- Multicolor registration capabilities.

- Clean room compatibility.

- Stroke counter.

- Three precision dial indicators mounted on X, Y, and angular micro adjustable table.

- Off contact dial indicator.

- Flood/print cycle replaces standard print/flood cycle. Flood hold switch is omitted.

- Automatic ink dispenser.

- Screen Tension Meter.

Typical Applications

- Kegs

- Fuel Cells

- Skis

- Panels

- Traffic cones

- Appliances

- Large Format Products