Cylindrical Screen Printing Machines

We provide a range of high-quality cylindrical screen printing machines featuring advanced engineering designs. Some of our machines can achieve automated printing rates of approximately 4,300 prints per hour, depending on the product. With over 40 years of experience in supplying screen printing equipment for diverse applications, we’re sure to meet your unique printing needs. Learn more about our cylindrical screen printers:

Printers for Small and Medium Format Cylindrical Objects:

The Model F1 series machines are known in the industry as “The most versatile screen printing machine ever made”. Brilliantly simple. Easy to operate. And versatile. Ideal for cups, bottles, glassware and more for full 360 degree image coverage. The Model F1-DC is dedicated for cylindrical products.

High speed, integrated air dryer with automatic loading and unloading of cylindrical products, up to 4,300 parts per hour. The Vinci prints small format products such as vials, syringe barrels and dosage cups.

The PT-8 series printer is a high speed, high accuracy, turret type screen printer designed for printing a wide range of cylindrical products. You can easily and quickly go from one product line to another with the user friendly dial changeover design.

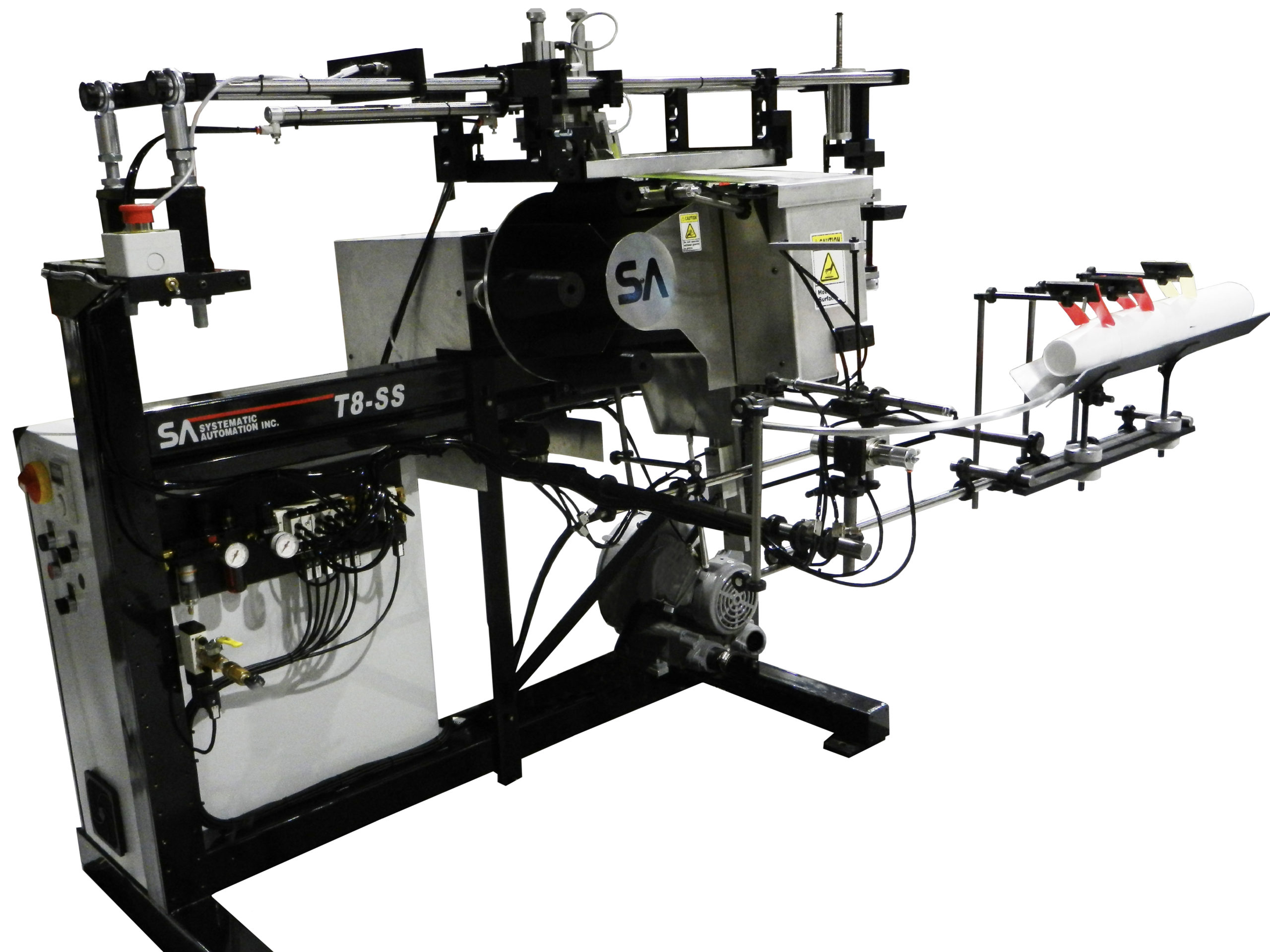

Automatic loading and unloading, pre-treatment and UV curing (LED integration available). Many customers use the T8-SS as a one stop solution for foam and plastic cups that range from small to stadium size.

Printers for Medium and Large Format Cylindrical Objects:

Simple design, low maintenance, rugged, reliable, with one to six color screen printing. Modular design for integration of processes such as pretreatment, multicolor, and automatic unloading. Print multiple products that vary in size.

The machine comes with three different sizes of tooling, which make it ideal for screen printing kegs of different capacities. You even have the option to print beer growlers & pint glasses, making this a one stop shop for printing the products in your industry.

Specialized Cylindrical Screen Printers:

At the heart of our ColorCup Pro is the Systematic Automation patented hollow ring indexer. Designed to produce quality prints for decades to come. Now anyone with basic knowledge can learn to produce amazing super opaque screen printed images.

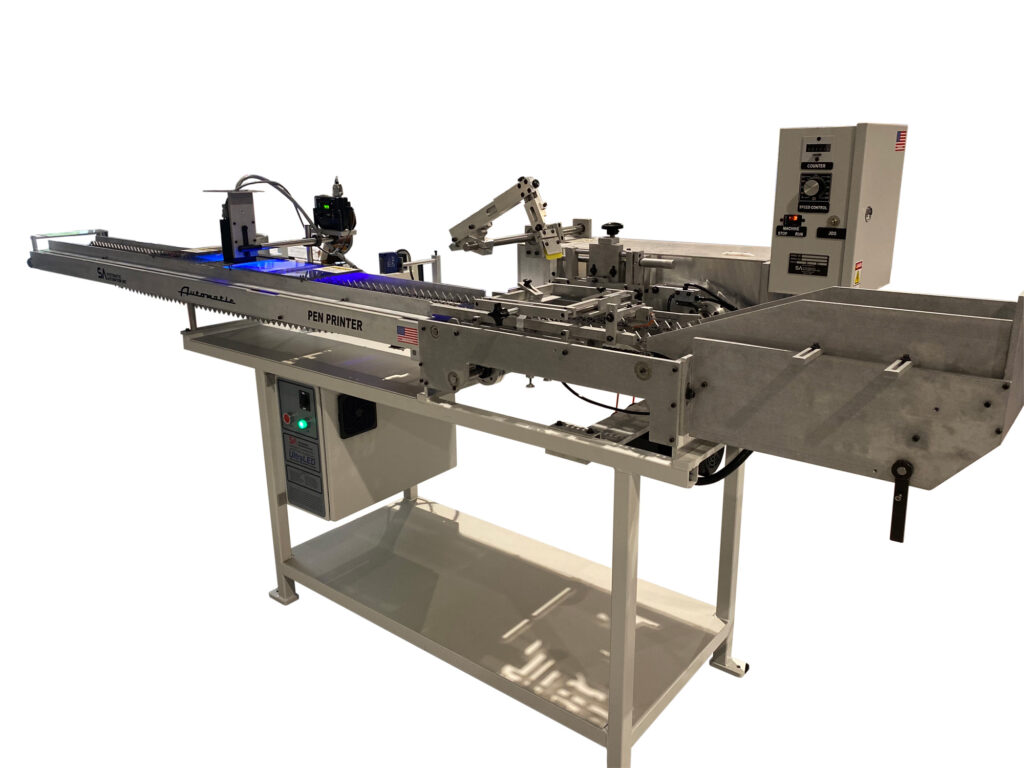

The PEN screen printer is your solution for automatically printing your pen catalogue. The simple design allows for user friendly operation. Print approximately 4,200 pens per hour.

Eight station indexer, ability to print on both sides of the Koozie in a single operation, auto dryer, sensor with electronic counter and audible smoke detector mounted to the top.

What is the Difference Between Flat Printing and Cylindrical Printing?

Flat printing means the substrate's printing surface is flat. Cylindrical printing means the substrate's printing surface is round. The rest of the substrate can have any shape to it.

When screen printing a flat surface, the screen is stationary above the printing surface about 1/16” (off contact). The squeegee presses the screen down to the product, then slides across the image on the screen and presses the ink through the image and onto the product.

When screen printing a cylindrical substrate, the screen is positioned approximately 1/16” above (off contact) the printing surface. The squeegee stays stationary and presses the screen down to the product, then the screen moves while the product spins at the same speed using the squeegee to press the ink through the image on the screen and onto the product.

Is My Screen Printing Machine Limited to Printing Only One Type of Product?

The modular design of Systematic Automation printers gives you the freedom to print a variety of products. For instance, printing flat to cylindrical can be done in less than a minute with the Model F1 — changing between pieces of cylindrical tooling only takes seconds.

Want to learn more about screen printing? We created a Screen Printing 101 resource page covering some of the most important questions we're often asked.

We Have The Right Cylindrical Screen Printing Machine For You

This is a sample line-up of our very popular cylindrical screen printing machines. In over 40 years of business we've perfected cylindrical screen printing on a variety of objects — from syringes and pens, to cups and mugs, to kegs and steel cylinders. If you have a specific product to print and don't see the right machine for it here, simply contact us and we'll work with you to design a custom machine.

Why Choose Systematic Automation For Your Cylindrical Screen Printing Machines

Systematic Automation is a leading manufacturer of screen printing machines for various commercial and industrial applications. With over 40 years in the industry, we have set the standard for innovative screen printing equipment and supplies. We have extensive experience designing, engineering and manufacturing several models of cylindrical screen printing presses.

Our economical cylindrical screen printing systems are tailored for your specific printing process. You can choose from automatic features such as UV curing, pretreatment, optical registration, and loaders & unloaders, among others. Levels of automation vary by machine model.

Our cylindrical screen printing machines can be customized to suit your particular application. We provide printing solutions across multiple industries, including promotional products, drinkware, automotive, aerospace, medical, and more. Reach out to us today — the experts in cylindrical screen printing machinery.