Vacuum Table Pumps And Valves

.5 HP Regenerative Vacuum Pump

- Continuous duty

- Quiet

- 56 cfm

- 45 in. water

- 120 volt 60 hz

- CE approved

- 45″ Hg max. vacuum

- 50″ max. pressure

- Aluminum alloy

The Vacuum Valves

The Vacuum Valve exhausts vacuum in the table when shut off. Standard valve for pump described to the left is vacuum on/off for 1 3/8″ vacuum hose (inside diameter) and requires a minimum of 80 PSI compressed air supply to operate.

Part # S1801000

The Vacuum Valve with Blowback blows air into the vacuum table. The valve diverts the exhaust of the vacuum pump (pressure) as supply air. The air flow into the table is easily adjustable in force and flow rate, using an adjustment lever on the valve. For 1 3/8″ hose (inside diameter).

Part # S1801001

Adjustable Vacuum Force Intake Valve

permits the reduction of flow to the vacuum table by allowing a controlled amount of air to enter the vacuum table.

Part # S4036M14

Foot Pedal for valve activation.

Part #S0122002

Regenerative Pump

Pros: Good holding power – better for high flow applications.

Used for light CNC machining, engraving, holding media

for printing, photography, keeping flexible materials flat.

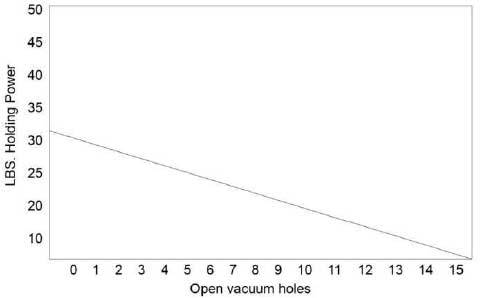

A few exposed holes in the vacuum table will not greatly

reduce the holding power.

Cons: Holding power is not as strong as a rotary vane pump.

Rotary Pump

Pros: Very strong holding power.

Used for CNC machining and other applications requiring

strong holding power.

Cons: Low flow – Open holes on the vacuum table or workpiece

will greatly reduce the holding power because of “low flow”.

May require sealing of workpiece on the vacuum table using

tape, clay or O’ring jig.

Vacuum Pump Holding Power

To help prevent damage to the vacuum table and vacuum pump, read the recommendations below:

Do not provide more vacuum to the substrate than needed. For example, if you find that 20’’ hg holding vacuum force is sufficient, then pre-vent the vacuum system using the adjustable vacuum gate located on the side channel of table until the gauge on the vacuum pump reads 20’’ hg. Maxing out the vacuum pumps available vacuum force may overheat and damage the pump.

Due to the cycling internal forces being put on the honeycomb construction by the vacuum force and the weight of the substrate, it is always recommended to keep vacuum force to a minimum to prevent deviation in the surface flatness of the vacuum table.

When starting the complete system for the first time, we suggest opening the adjustable vacuum gate located on the side channel, then adjust accordingly.