VACUUM FORMING AND THERMOFORMING

In need of an efficient and cost-effective method of creating prototypes? Choose Systematic Automation for vacuum forming and thermoforming excellence.

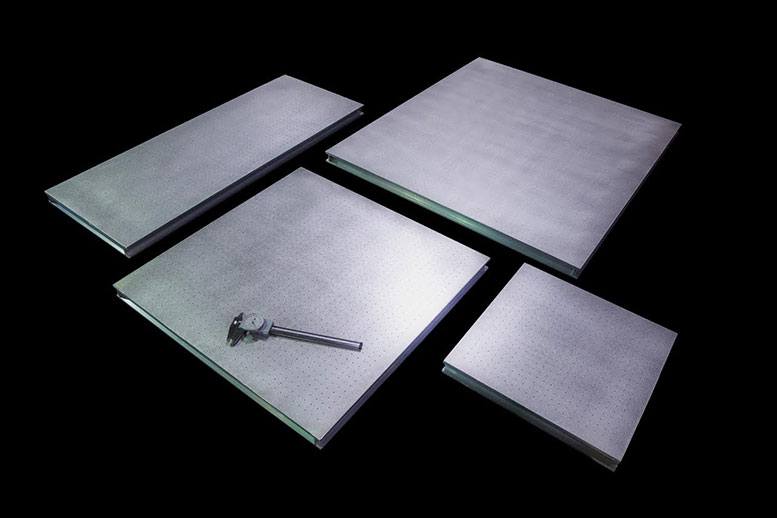

Our vacuum tables are an essential component in achieving industry-standard quality. For more than 30 years, Systematic Automation has been a trusted supplier of vacuum tables to the thermoforming industry, providing precision flatness that is unmatched. Our vacuum tables offer flatness within +/-.001″, ensuring that your molds for components are incredibly precise.

There are two methods of thermoforming: vacuum forming and pressure forming. Vacuum forming involves heating a plastic sheet until it is pliable and then pressing it against a 3D mold by vacuuming the air between the sheet and the mold. This process allows for sharper details and molded texture.

Pressure forming, on the other hand, applies air above the plastic sheet at the end of the process, allowing you to create complex shapes with tight tolerances. Both vacuum forming and pressure forming can benefit from the precision flatness of our vacuum tables, making them an essential tool for any thermoforming operation.

In need of custom options? We are so committed to customer satisfaction that we also offer customization using your exact specifications, including size and hole patterns, making them ideal for vacuum forming and thermoforming applications.

Equipment Features

Systematic Automation super precision vacuum tables provide a flatness of +/-.001″ (.025mm) per linear foot, making it the flattest vacuum table available. Additionally, we provide an array of features and customizable options to complement the vacuum table for your vacuum forming and thermoforming operations, such as:

- Custom shaped vacuum tables

- Custom designed zones with valves

- Custom hole patterns

- Custom bases

- Sliding vacuum tables

- Heated vacuum tables

- Automatic pin registration

- Formica table surface

- Anodized table surface

Value Added Services

Our knowledgeable engineering department will assist you in selecting the optimal size vacuum table, type of pump best suited for your needs, and port location. Our precision vacuum tables are available with vacuum port connections from any side of the table, or at any location from the bottom of the table.

You can also call on Systematic Automation to resurface your current vacuum table, applying our extensive knowledge in manufacturing precision vacuum tables to providing superior engineering enhancements to your current product.

At Systematic Automation, we have vast experience in providing the most cost-efficient solution for your application requirements. With our customized approach, we make sure that you get the vacuum system required for your application, without paying more than you need to.

Systematic Automation is recognized as a leading global supplier of vacuum tables, with experienced engineers providing customized solutions. We provide exceptional customer service and ongoing support to ensure success of your installation. Contact us today to learn more about our high-performance vacuum tables for vacuum forming and thermoforming.

Looking for a different vacuum table?

We have a large variety of tables available.