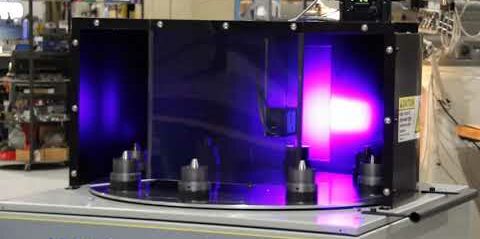

UVSP | UV Curing Machine

- Ideal for glassware, bottles and more.

- Product is rotated parallel to the UV source focal point – 6″(154mm) & 12″(305mm).

- Exclusive revolving door design protects operators from escaping light.

- Universal vacuum product handling.

- Large systems available – up to 25″(635mm) lamp sizes

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Product Description

(U.S. Patent # 6,397,491 B1)

• True 360-Degree Curing: Provides direct, focused 360-degree UV exposure, unlike typical “spin on the fly” systems. No need for mirrors, which reduce UV intensity by over 60%.

• Energy-Efficient: Reflectors maximize light by redirecting it back onto the product surface, ensuring consistent curing while saving energy.

• Uniform Results: Entire print area is rotated through a UV focal point, guaranteeing uniform curing across cylindrical surfaces.

• Versatile Product Holding: Universal vacuum plates securely hold most cylindrical products, with optional dedicated tooling for unique shapes.

• Reliable & Smooth Operation: The Geneva indexer with overload clutch provides smooth, harmonic movement driven by a robust 110V variable-speed AC Tech brushless motor.

Experience reduced costs, increased uptime, and unparalleled curing quality with the UVSP UV Curing Machine—designed for those who demand high ROI and top-notch performance.

Features

Engineering Features

- Part flexibility for cylindrical and irregular shaped items. Sizes from ball point pen barrels to gallon containers.

- Entire print area is rotated through the UV focal point to maximize the effect of the UV light rays. Uniformity of cure is guaranteed.

- Exclusive revolving door design protects operators from escaping light.

- Rotating through the UV focal point allows for the fastest cycling time while ensuring thorough, consistent curing.

- Once parts are loaded, no rollers, belts, or escapements adjust. Changeover from one part to the next can’t get any easier.

- Overload clutch.

- Machine control technique entirely eliminates the problem of electrical component obsolescence.

- Geneva indexer provides harmonic (smooth acceleration and deceleration) dial motion.

- Whether curing inks, coatings, or adhesives, the UVSP system allows adjustment of indexing and rotation speed as well as UV intensity.

- Compact design.

- Affordable price.

Standard Features

- Length 48″ (1219 mm).

- Width 36″ (914 mm).

- Height 60″ (1524 mm).

- Sizes: 6″ (152 mm) lamp, 12″ (304 mm) lamp, 18″ (457 mm) lamp and larger versions available built to your specifications.

- Maximum substrate height 15″ (381 mm).

- Maximum substrate diameter 14″ (356 mm).

- Variable speed AC motor control with digital readout.

- 400 watts per inch for 6″ (152 mm) lamps. Tri-power (200/300/400 watts per inch) available.

- Tri-power (200/300/400 watts per inch) standard for 12″ (304 mm) and longer lamps.

- Electrical requirement for 6″ (152 mm) system: 208-240 volts, 1 phase, 60 HZ.

- Electrical requirement for 12″ (304 mm) system: 208-480 volts, 1 phase, 60 HZ.

- Machine weight: 600 lbs. (272 Kg).

Featured In

Typical Applications

- Pint Glasses

- Plastic Bottles

- Growlers

- Shot Glasses

- Mugs

- Drinkware

- Glassware

- 3D Objects