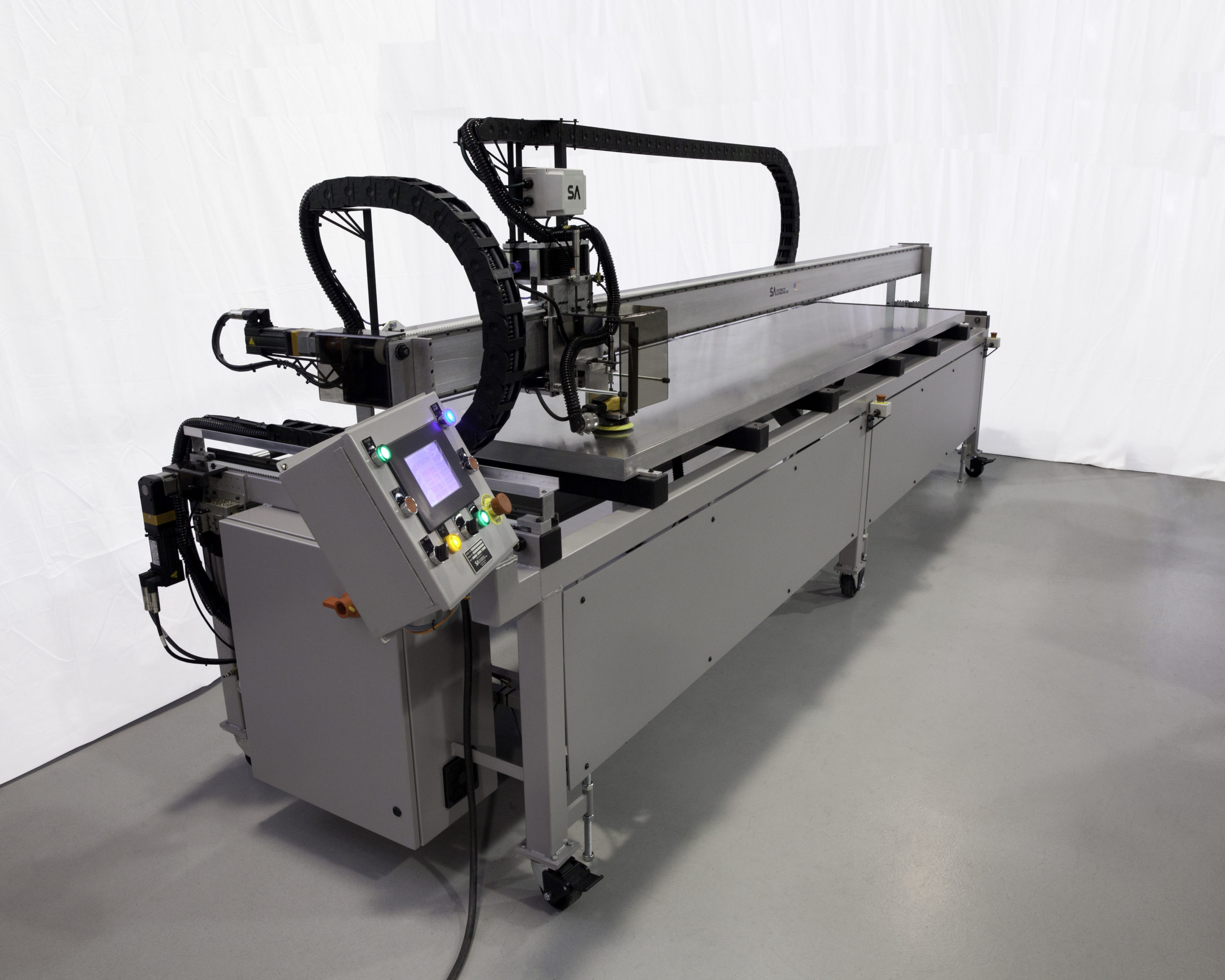

Super Glide – CNC Sanding

- Automatically sand your products.

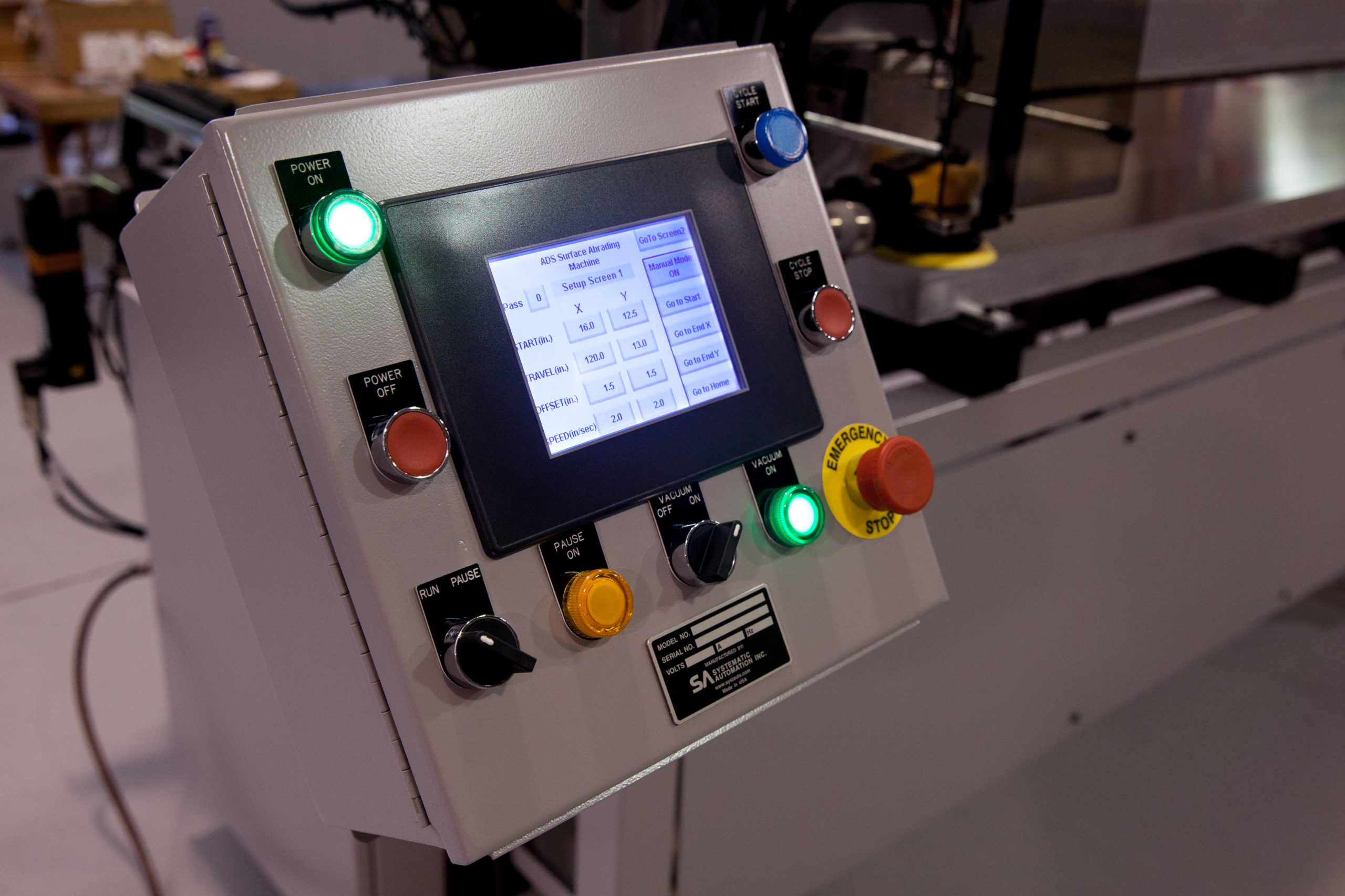

- Easily program your sanding parameters.

- Extreme durability for continuous fabrication.

- Vacuum integration for debris collection.

- Vacuum table hold-down.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Product Description

• Versatile for Multiple Applications: The Super Glide CNC Sanding Machine provides consistent, high-quality sanding, grinding, and polishing for a range of flat materials including aluminum, steel, resins, wood, topcoats, fiberglass, and other solid surfaces. Designed to handle everything from heavy-duty sheet metal sanding to polishing softer materials, this machine offers unparalleled versatility.

• Precision and Durability: With industry-leading tolerances and a vacuum table for precise hold-down, the Super Glide ensures an incredible flatness of +/- .001” (.025mm) over a ten square foot span. This level of accuracy delivers consistent quality across products, ideal for high-standard sanding applications.

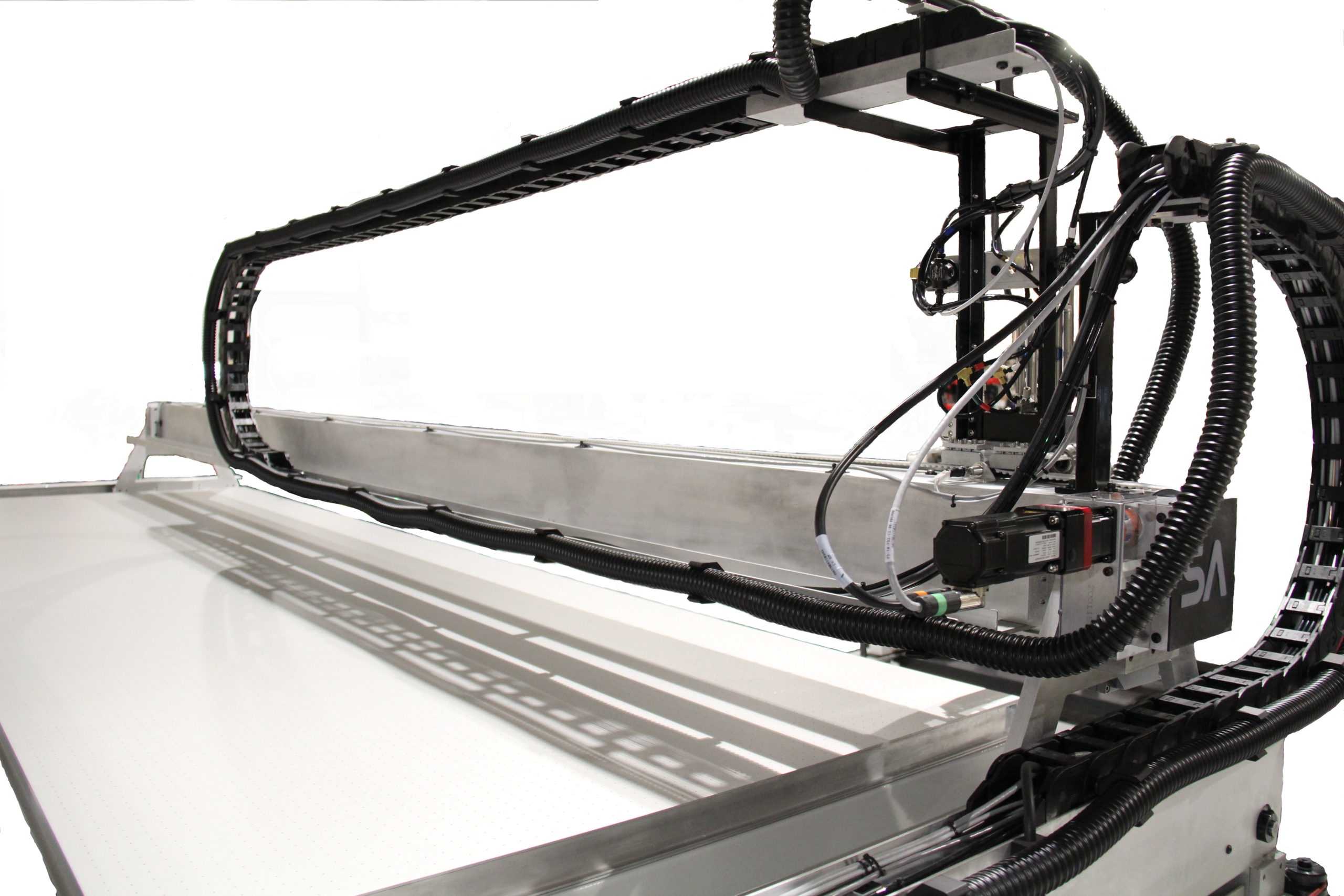

• Advanced Mirka Ceros DC Brushless Motor Technology: Utilizing the latest in orbital sanding, the Mirka Ceros DC sander features a virtually silent operation (68 dB), variable speed (4,000-10,000 rpm), and a three-year guarantee for dependable use. Integrated vacuum collection keeps work areas clean and minimizes debris.

• Enhanced User Control and Comfort: The user-friendly control panel allows easy parameter adjustments to suit each job, while vibration reduction and constant temperature monitoring protect the motor, extending durability and minimizing maintenance.

Choose Systematic Automation’s Super Glide CNC Sanding Machine for reliable, repeatable sanding performance that brings quality and precision to every project.

Sizes Available

Custom Sizes Available Upon Request

Size 1 Machine:

- 72″ X-axis travel, 36″ Y-axis, 3″ Z-axis.

- Vacuum table 72″ x 36″.

- Max sheet size for completely sanding sheet – 66″ x 30″.

Size 2 Machine:

- 108″ X-axis travel, 60″ Y-axis, 3″ Z-axis.

- Vacuum table 108″ x 60″.

- Max sheet size for completely sanding sheet – 102″ x 54″.

Size 3 Machine :

- 144″ X-axis travel, 84″ Y-axis, 3″ Z-axis

- Vacuum table 144″ x 84″

- Max sheet size for complete sanding – 138″ x 78″

Standard Machine Features :

- 2 Axis servo motor controls Touch screen interface.

- 5″ Diameter Mirka Sander Dust collection.

- Heavy duty machine base Vacuum table flatness within +/- .001″ per linear foot.

- 1/16″ diameter vacuum holes on 0.75″ centers.

Why Choose the Super Glide

The SA Super Glide CNC sanding system is made for any abrading process that you want automated, particularly those that are large format. The Mirka Orbital Sander that comes integrated with the system has interchangeable sanding pads. From film to steel, the Super Glide will provide a programmable and reliable automatic solution to your sanding jobs. The machine will pay for itself in freeing up your labor and ensuring every piece under the system is thoroughly sanded without any worries over respiration issues that arise from your material. Mirka includes patented abrasive Abranet pads that come with the system that provides you with industry leading quality. The pad includes an open weave net, which will not allow dust particles of more than 0.5mm through the dust extraction hole. Film backed abrasives are smooth, flexible and ideal for scratch resistant clearcoats. Paper backed abrasives are durable, ideal for high speed sanding on a variety of different materials. Cloth backed abrasives are for machine sanding with outstanding resistance to wear and tear- typically used for jobs that require sanding to remove larger areas of material. Sanding resin is important to ensure you have flat and even surface after curing. As you can probably surmise, there are a variety of different resins, luckily all of which have a sanding pad that can be used on the Super Glide. Epoxy resin may be extremely hard to work with, which may require the surface to be wet, waterproof sanding methods will make the job easier. Silicon carbide pads are ideal for this application. Adding water to your resin will also minimize the dust amount, however the Super Glide has a function to vacuum excess particulates. Water will also minimize the heat, which may cause the resin to dissolve and affect the surface flatness. When you are sanding your aluminum, silicon carbide pads are the best for your process, whether you are trying to smooth the surface or removing material on top. When sanding on metal, a minimum of 320 grit is recommended. Raw aluminum can be sanded/polished to a near reflective surface. Sanding aluminum manually without SA equipment or masks/goggles may cause the worker to develop acute symptoms caused from aluminum toxicity, some symptoms may become chronic.