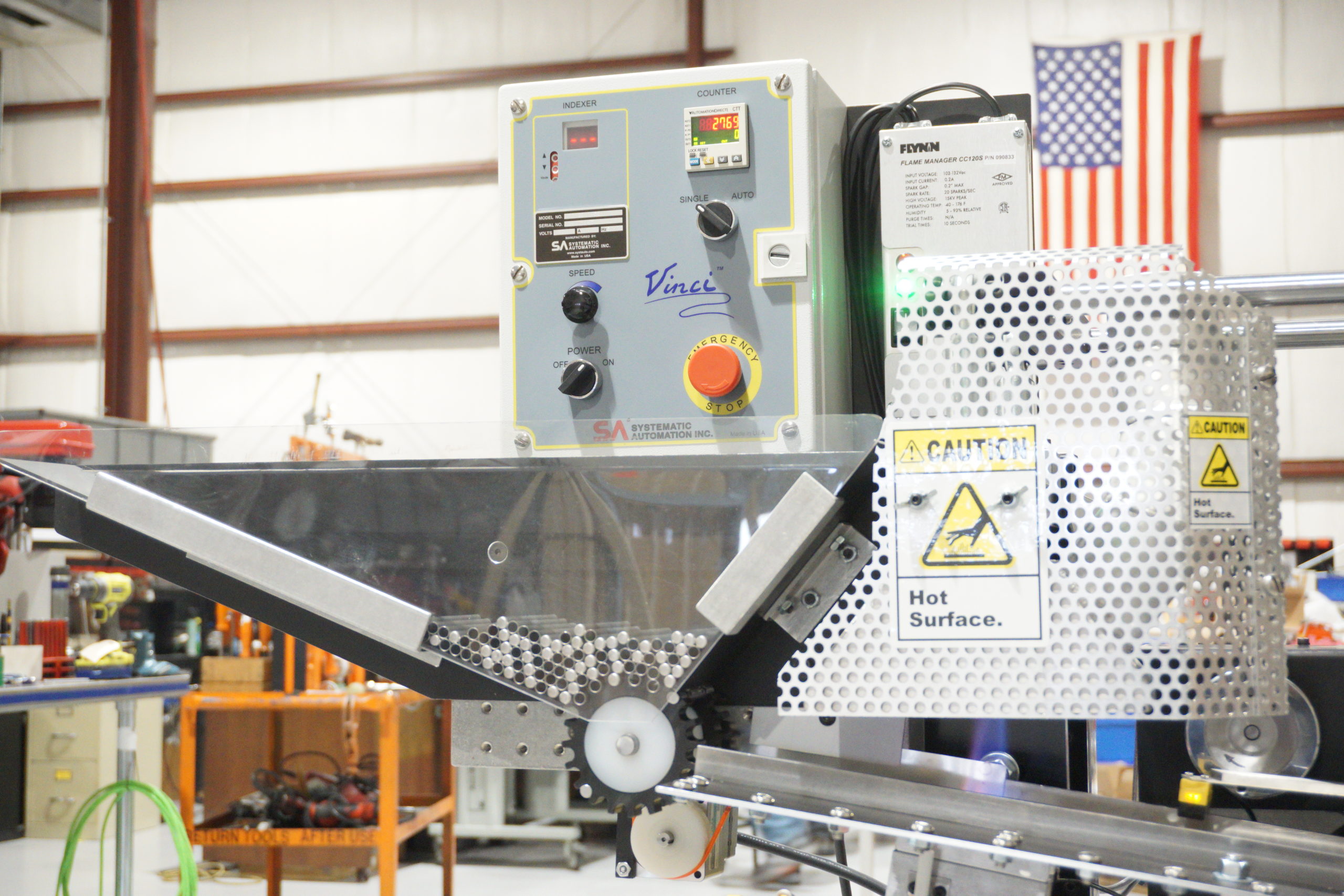

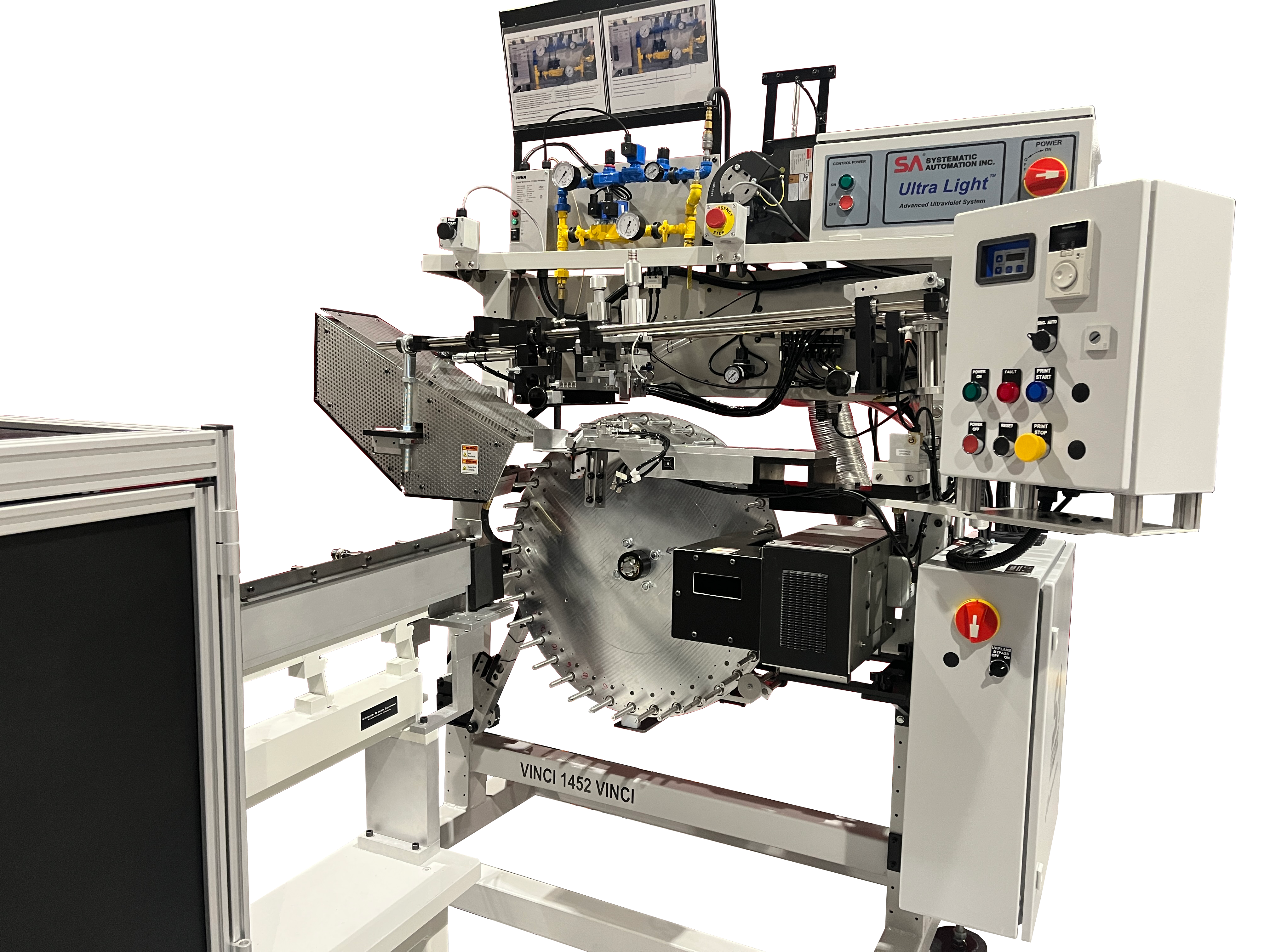

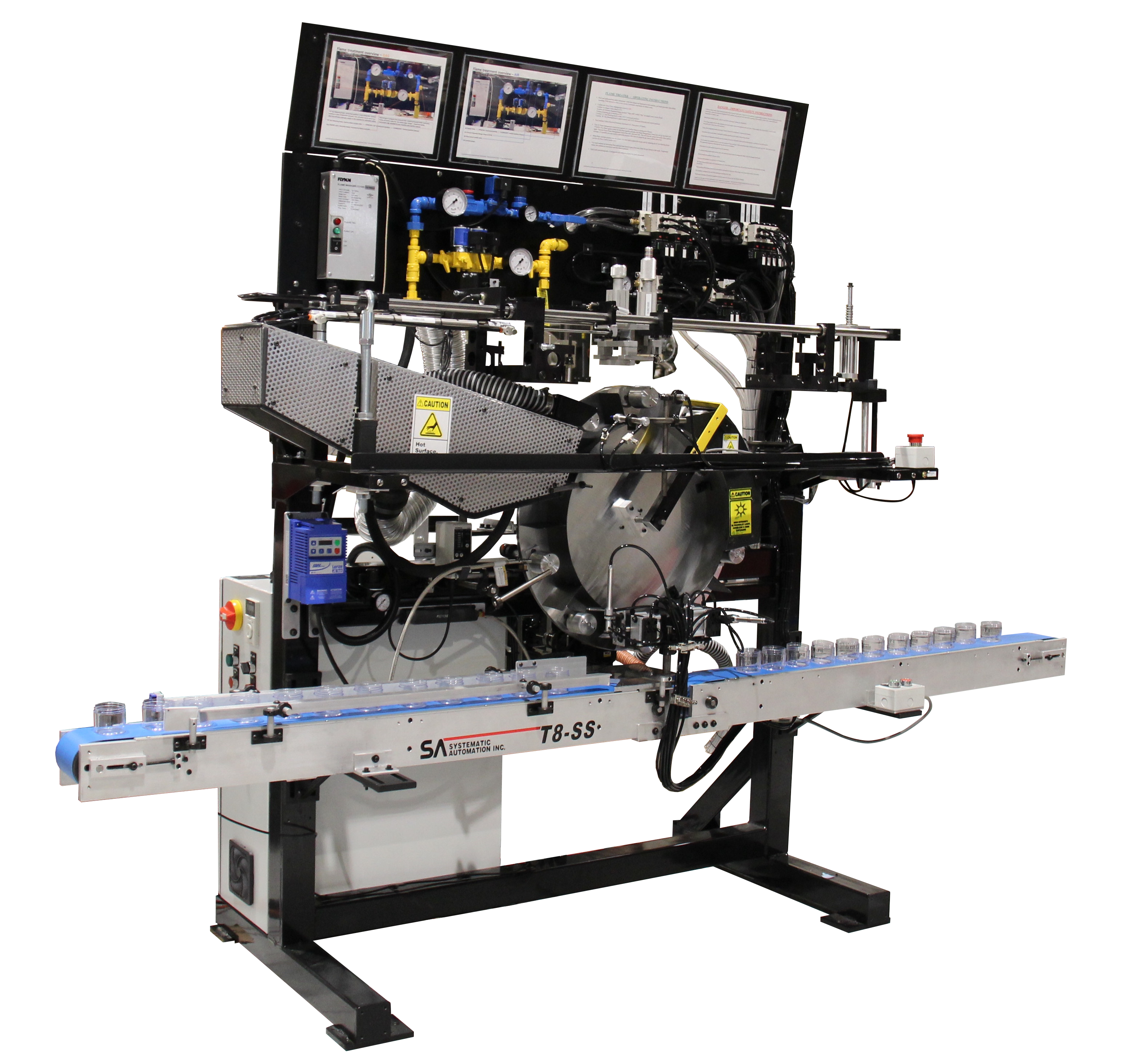

Vinci 1452 Screen Printing Machine

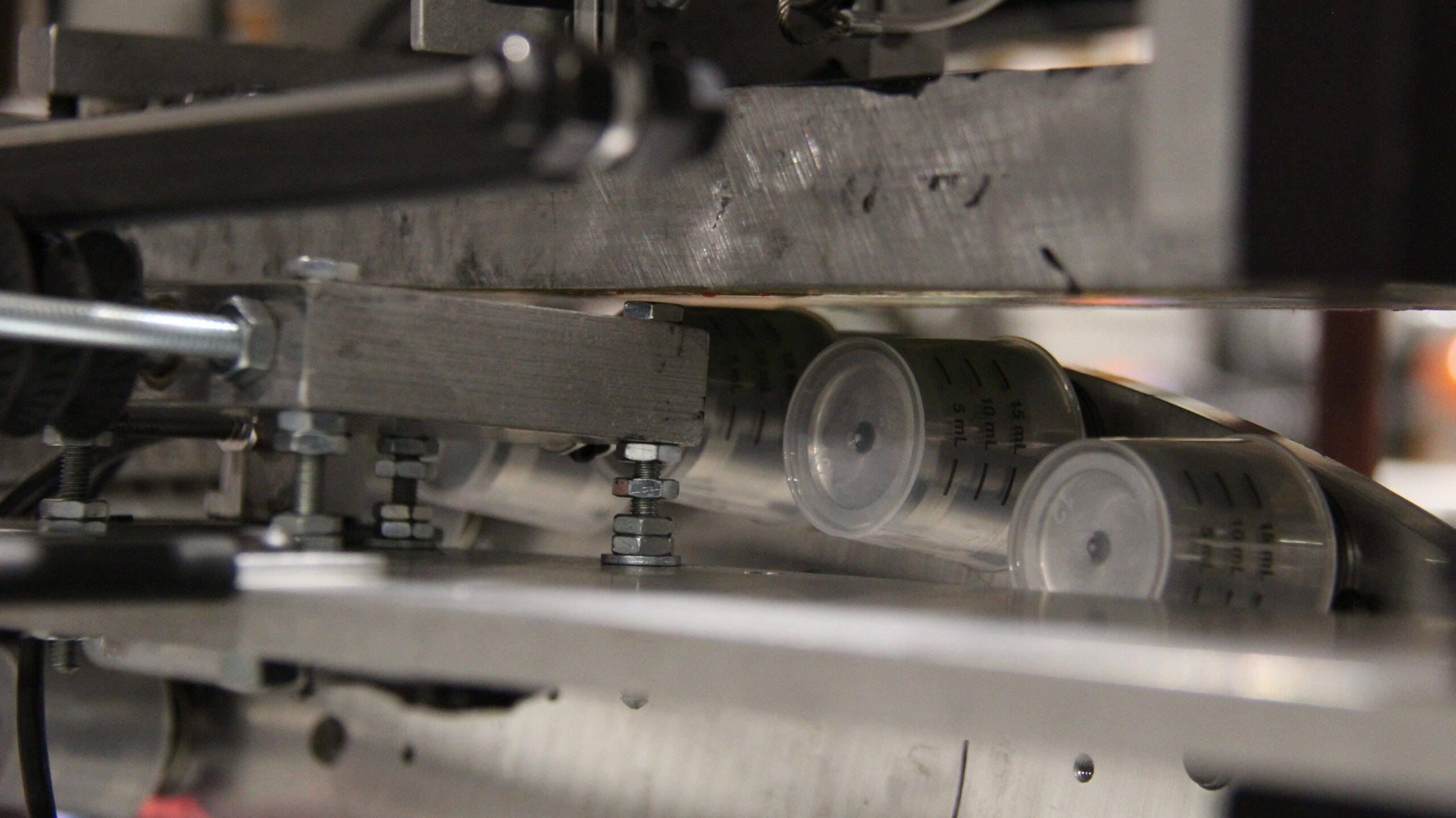

- Ideal for syringe barrels, chapstick containers, spark plugs and more.

- Print up to 4,300 parts per hour.

- Fully mechanical design.

- Pneumatic system cannot overload, burn out or become obsolete.

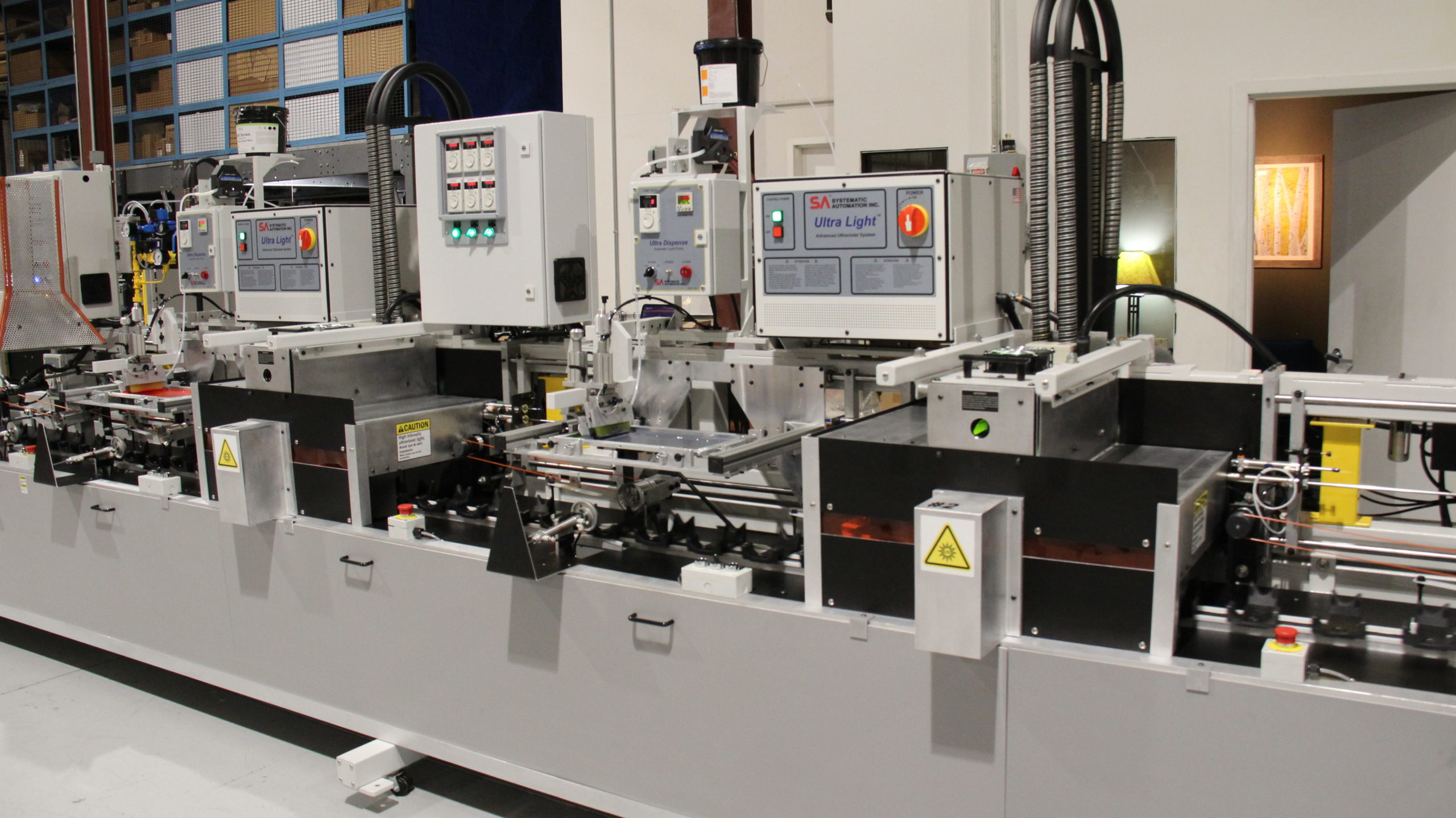

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Product Description

Speed, Simplicity, and Reliability

English Data Sheet | Spanish Data Sheet

• High-Speed Output: Achieve up to 72 parts per minute, allowing for millions of parts printed annually. Rated for continuous operation—24/7 across three shifts.

• Easy Maintenance and Operation: Unique high-speed indexer and cam-based controls make running and maintaining the Vinci 1452 remarkably straightforward.

• Quick Product Change-Over: Switch between products in minutes with a swing-out dryer for access, plus one-step dial and tooling removal—tasks that take hours on other machines.

• Optional Enhancements: Customize with a vibratory bowl feeder, LED, UV, or hot air curing, vision systems, flame/FieroSil pretreatment, anti-static systems, and a conveyor for unloaded parts.

Choose the Vinci 1452 for unmatched speed, ease of use, and durability—built for high-volume production and adaptable to your exact needs.

Features

Vinci 1452 Features

- Print up to 4,300 parts per hour.

- Quick changeover between one dial with tooling to another.

- Fully mechanical design allows for very low upkeep.

- Pneumatic system cannot overload, burn out or become obsolete.

- Machine tool quality and durability.

- 100% Manufactured in USA.

- Stainless steel air cylinders.

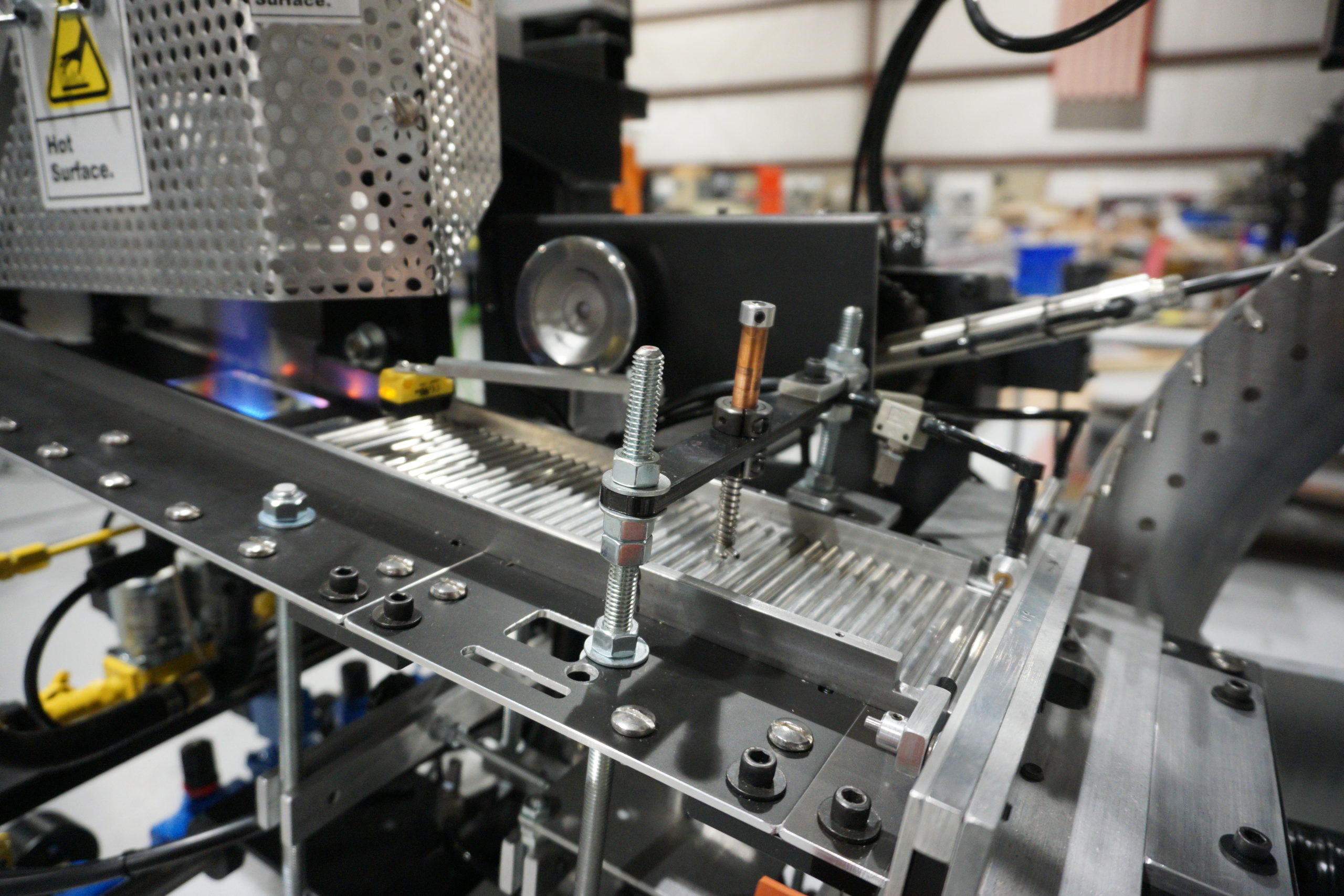

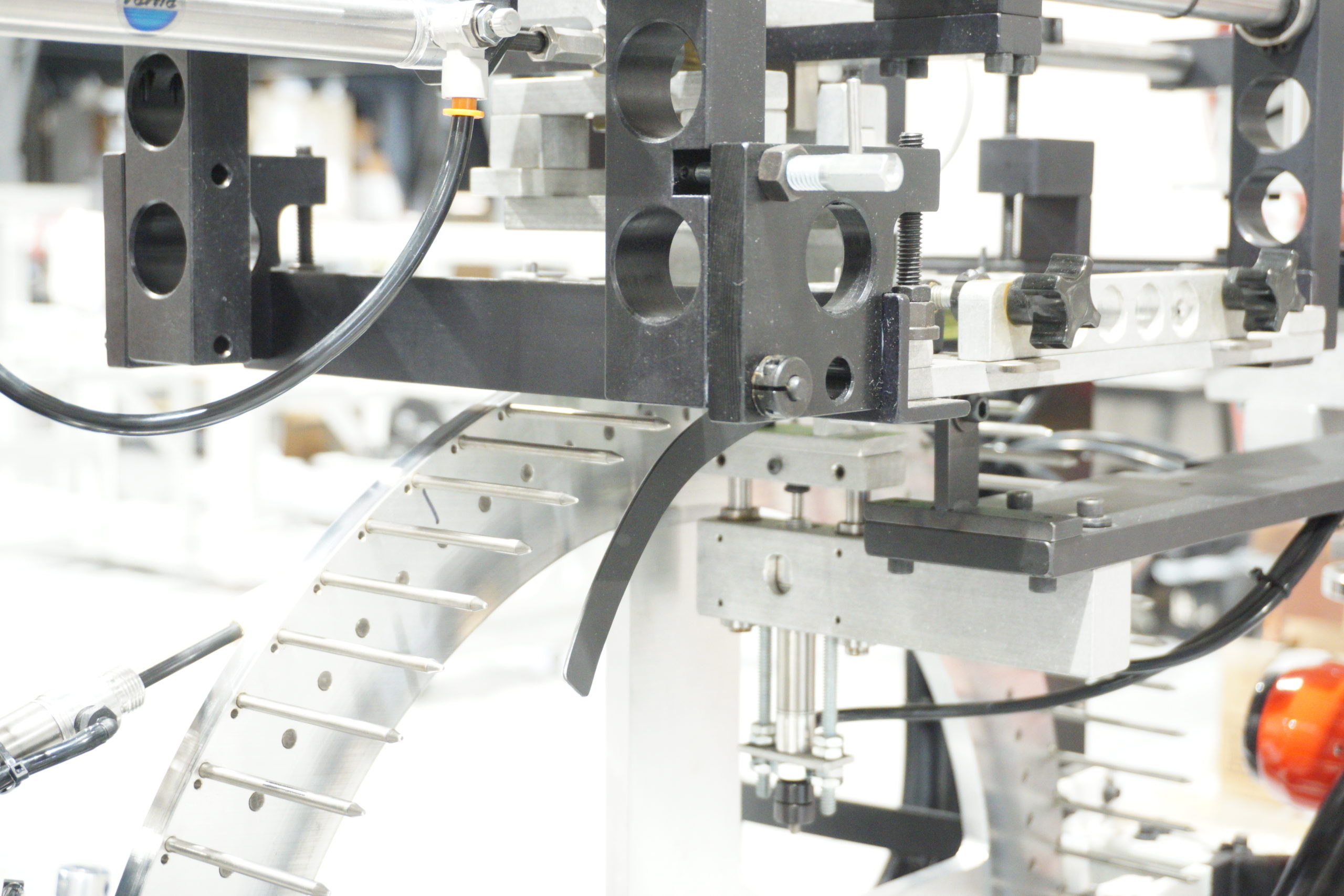

- Hardened, ground, and polished shafts with linear ball bearings rated at over 300 million cycles.

- Vertical dial indexer with 72 stations.

- The dryer swings out of the way allowing access to the printer dial and part tooling.

- Easy maintenance.

- Universal screen mounting.

- Smooth, quiet operation.

Standard Features

- Variable flood bar speed.

- Adjustable print stroke length.

- Operating pressure adjustment with gauge.

- Air shut-off switch.

- Automatic loading.

- High speed machine indexer.

- Integrated hot air drying.

- Automatic unload.

- One full set of product tooling.

- Heavy-duty welded steel base with casters and tote bins.

- Squeegee holder.

- Independent squeegee/flood bar micro height adjustment.

- Pneumatic control panel.

Pretreatment

Your product surface may require pretreatment to promote ink adhesion. Products ordered in bulk may have oil contaminants or other residue as well as having poor surface tension, which can be remedied by flame pretreatment. Pretreatment integration is done by installing a burner on your machine that will provide flame to your entire surface area. If your product is cylindrical, it will spin 360 degrees, parallel with the burner and if it is flat, the flame system will move to cover your product area. Burners are made in house and to size. Pretreatment is done prior to printing your product.