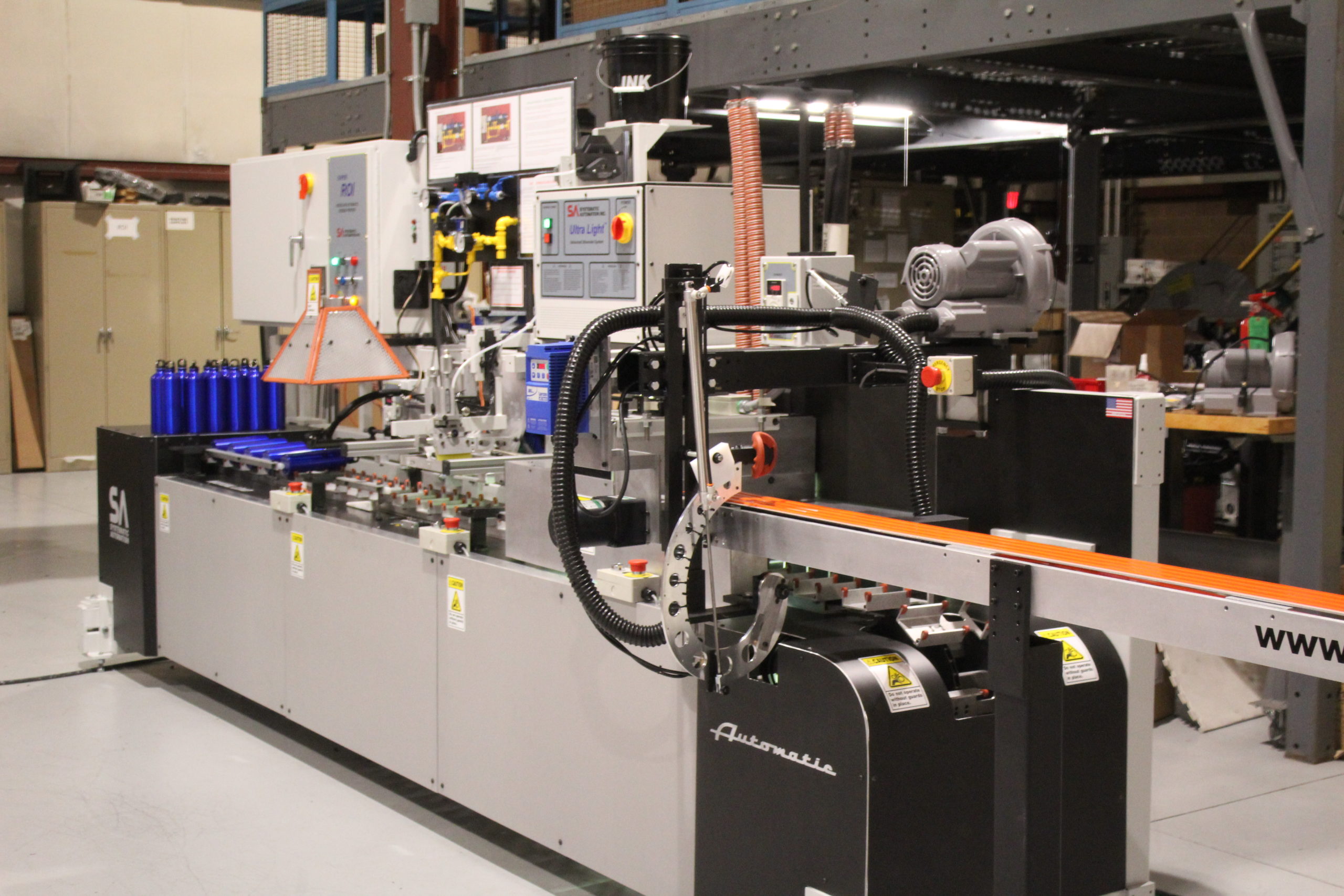

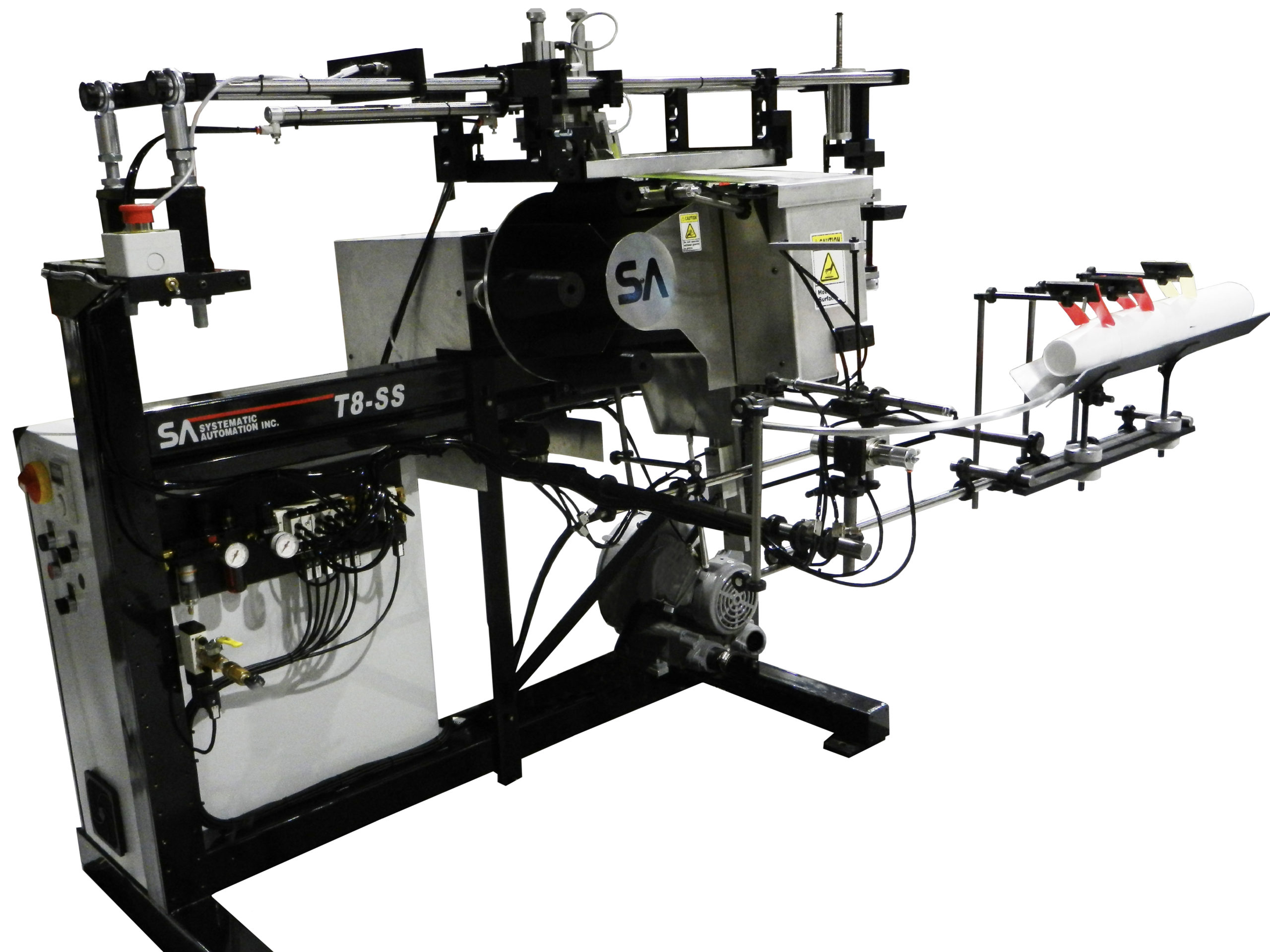

Super ROI Screen Printing Machine

- Ideal for cups, glassware, bottles and oil filters.

- Servo driven indexer.

- Approximately 3,600 prints per hour (depending on product).

- Modular design permits process integration and automated loading/unloading.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Product Description

Increase Your Throughput & Simplify Your Printing Process

English Data Sheet | Spanish Data Sheet

• Built to Last: With its rugged, modular construction, the Super ROI performs consistently for decades. No complex computers or control boards—just reliable, easy-to-service machinery.

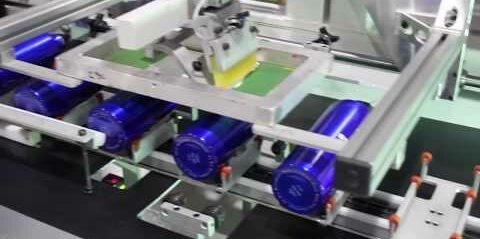

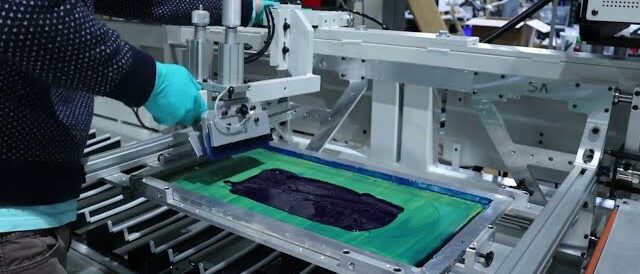

• Precision Multi-Color Printing: Offers one to six-color options using award-winning SA screen printer assembly and energy-efficient Ultra Light UV System.

• Efficient Substrate Handling: Linear transport with minimal lifting ensures smooth, efficient substrate movement, reducing handling and simplifying operation.

• Versatile Options: Integrate pretreatment, UV LED curing, and loaders/unloaders as needed. The Super ROI’s flexibility suits a range of production needs.

• Streamlined, Fast Output: Hand or robot-load cylindrical products onto a spacious loading area. The ROI detects, flame-treats (optional), prints, UV cures at 400 WPI, and takes off, achieving high throughput effortlessly.

• Versatility Across Industries: Whether you’re producing custom beverage bottles, cosmetic containers, or promotional items, this machine handles a wide variety of cylindrical substrates with ease. Its adjustable features ensure seamless adaptability for different sizes and shapes, making it the perfect solution for businesses catering to multiple industries.

• Comprehensive Training and Support : Each Super ROI comes with detailed training and ongoing support to ensure your team is equipped to operate the machine effectively. From installation to troubleshooting, we’re here to help you get the most out of your investment.

• Proven ROI for Your Business :With increased production capacity and reduced overhead costs, the Super ROI delivers exceptional value. Many of our clients report full ROI within 12 months, thanks to its unmatched efficiency and quality.

Experience unmatched reliability and productivity with the Super ROI—designed for businesses that need top performance and low maintenance costs in screen printing.

Super ROI Machine Overview

Features

Engineering Features

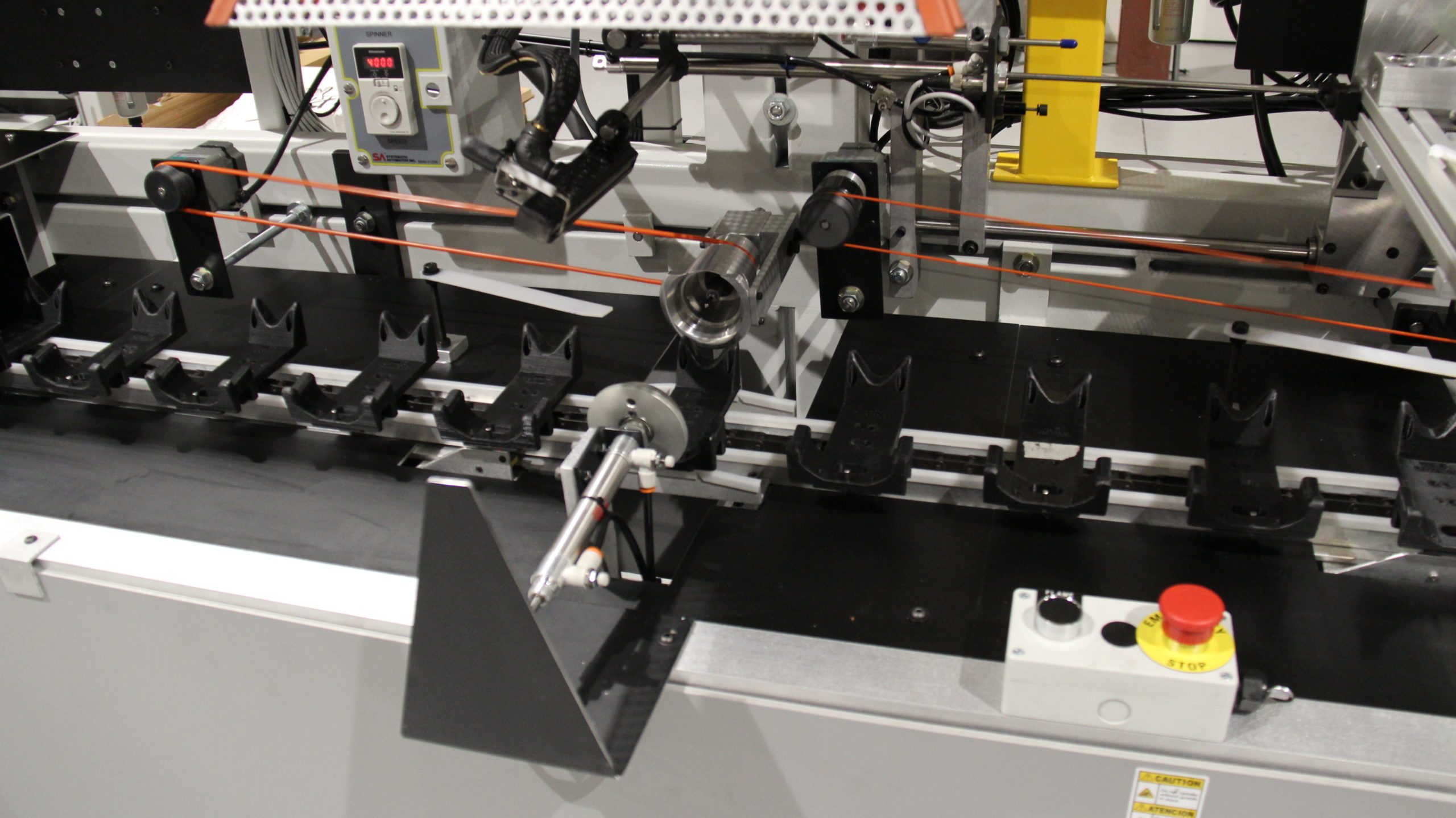

- Print a variety of different products using the same machine.

- Quick and easy product changeover.

- Machine tool quality and durability.

- Modular design allows for integration of different processes into system.

- Servo driven indexer.

- Low maintenance lube free drive system.

- Allen Bradley user friendly touch screen display.

- Indexing system is overload/crash protected.

- Adjustable squeegee and flood stroke speed.

- Operator protection from UV light and mechanical pinch points while maintaining free access to the loading station and screen printers.

- Designed for continuous duty operation.

- Precision linear motion bearings on the printer and substrate transport mechanism are rated at over 300 million cycles.

- Stainless steel printer shafts to resist corrosion.

- Worldwide availability of spare parts.

Standard Features

- Adjustable operating speed.

- Adjustable print stroke speed.

- Adjustable flood stroke speed.

- Adjustable squeegee pressure with gauge and regulator.

- Emergency stop.

- Single cycle/automatic mode selector switch.

- UV spin speed control.

- Part up/down speed control for print station and UV curing system.

- 20” (508 mm) stroke print head.

- All necessary squeegee holders, squeegee material, and flood bars (specify size).

- Touch screen display with operator control panel, PLC based control,servo drivers and motors.

- 6” (152 mm) UV Ultra Light system single power 400 WPI (watts per inch) power supply, and UV irradiator.

- 6” (152 mm) air cooled shutter system.