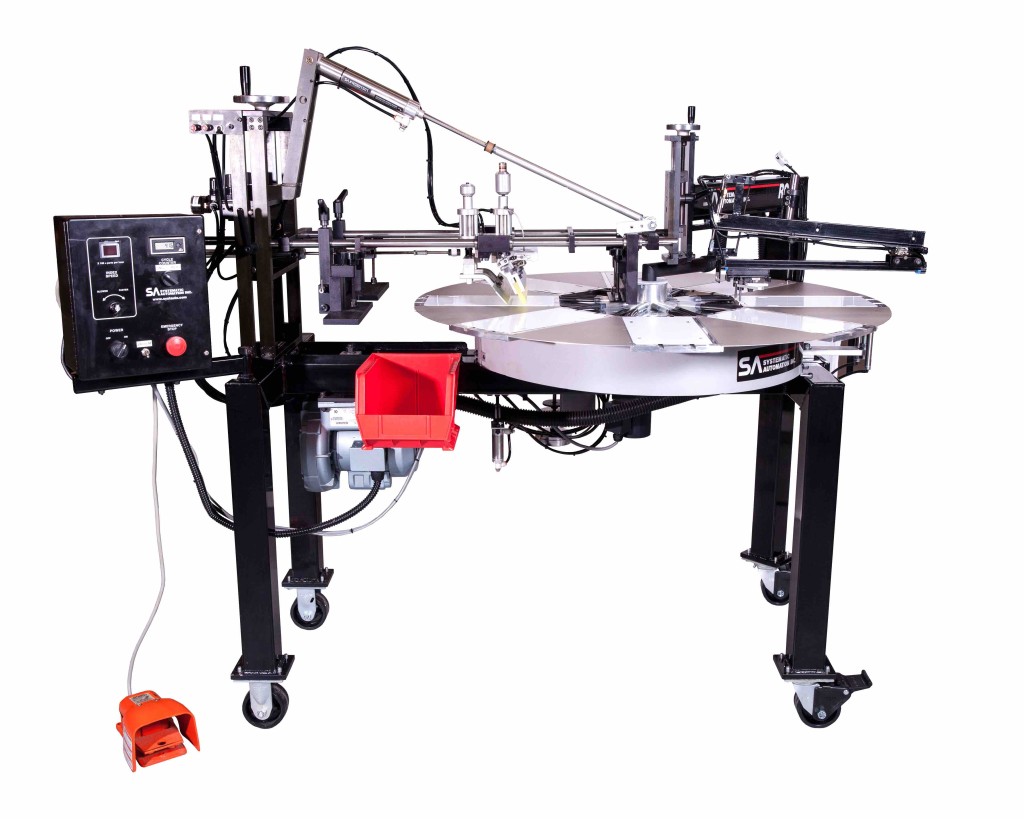

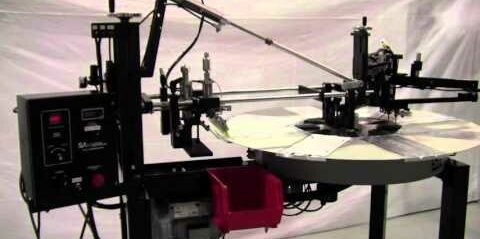

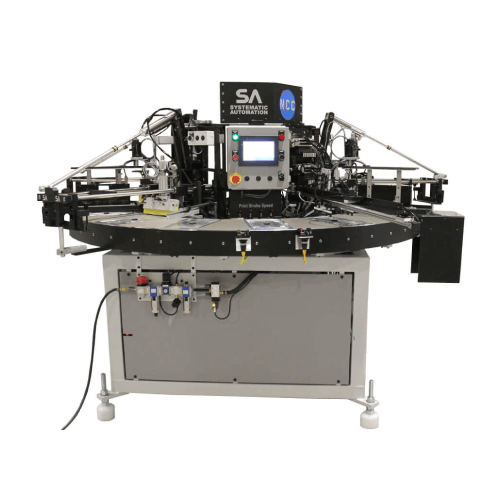

RC-1 Screen Printing Machine

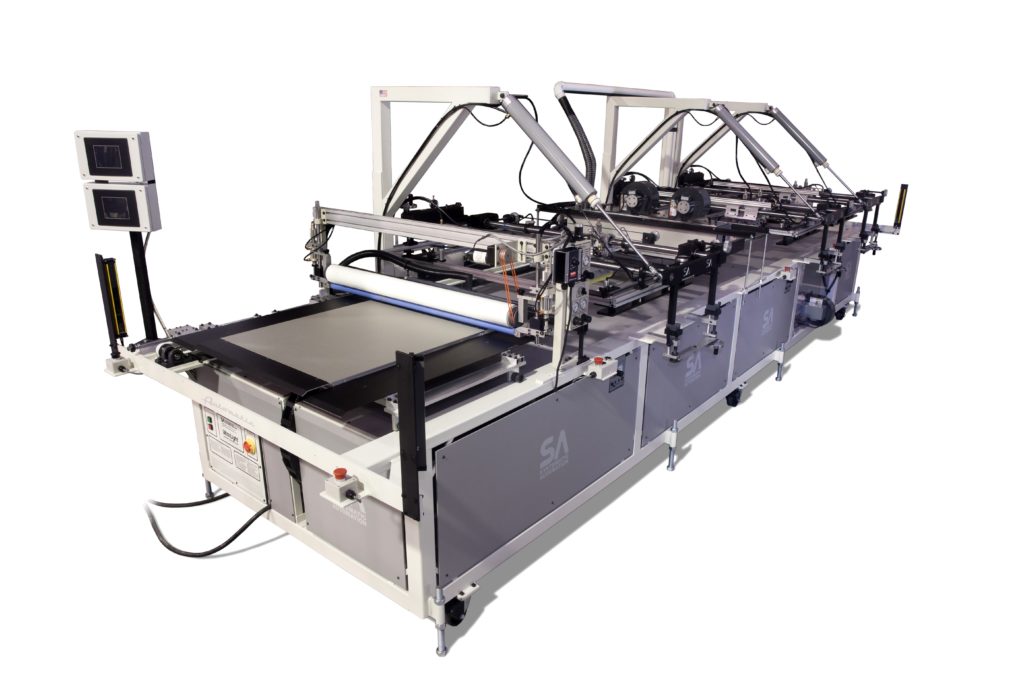

- Ideal for printing any flat surface

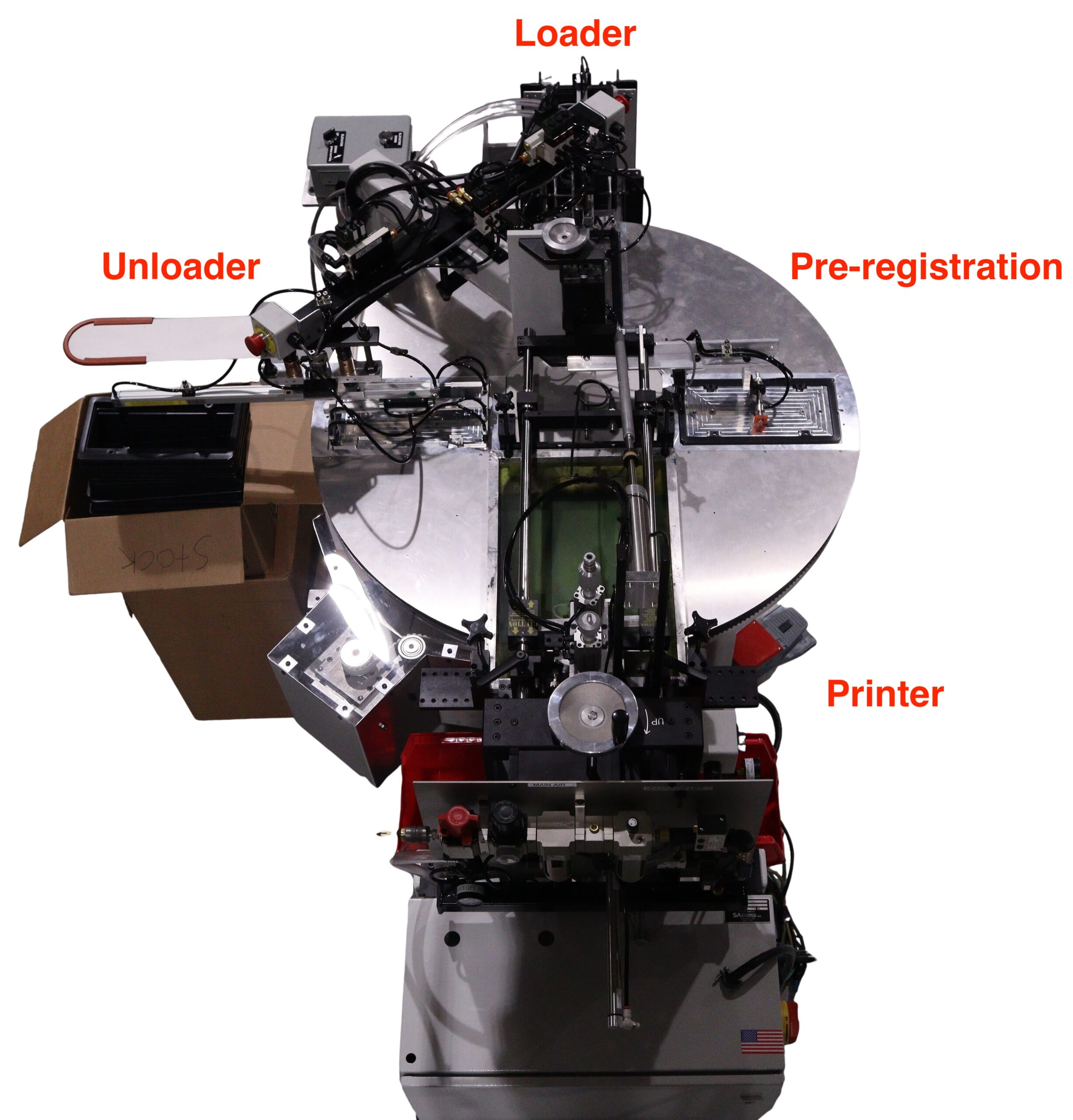

- Optional integrations such as loader and unloaders to automate your printing process.

- Approximately 1,800 prints per hour (depending on product).

- Machine can operate in single cycle or fully automatic mode.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Product Description

Quick, Accurate & Modular

English Data Sheet | Spanish Data Sheet

• Dependable Engineering: Powered by a 110V AC Tech brushless motor with an all-mechanical Geneva indexer for smooth, harmonic motion—ensuring durability and continuous operation.

• Simple, Maintenance-Free Control: Designed without a PLC, the RC-1 uses an innovative cam box controller, eliminating electrical obsolescence issues and allowing easy program adjustments with basic tools.

• Flexible Applications: Originally created for advertising specialties, the RC-1 is perfect for medium to high-volume printing on glass, ceramics, electronics, cosmetics, and automotive parts, handling challenging 3D products with ease.

• Affordable and Serviceable: With an overload clutch for safety and a design manufactured in Connecticut, this machine offers long-lasting, trouble-free operation that operators can easily service.

The RC-1 combines rugged performance and cost-efficiency—ideal for companies seeking reliable, high-quality printing on a range of materials.

Features

Engineering Features

- Machine tool quality and durability.

- Stainless steel air cylinders.

- 100% made in USA.

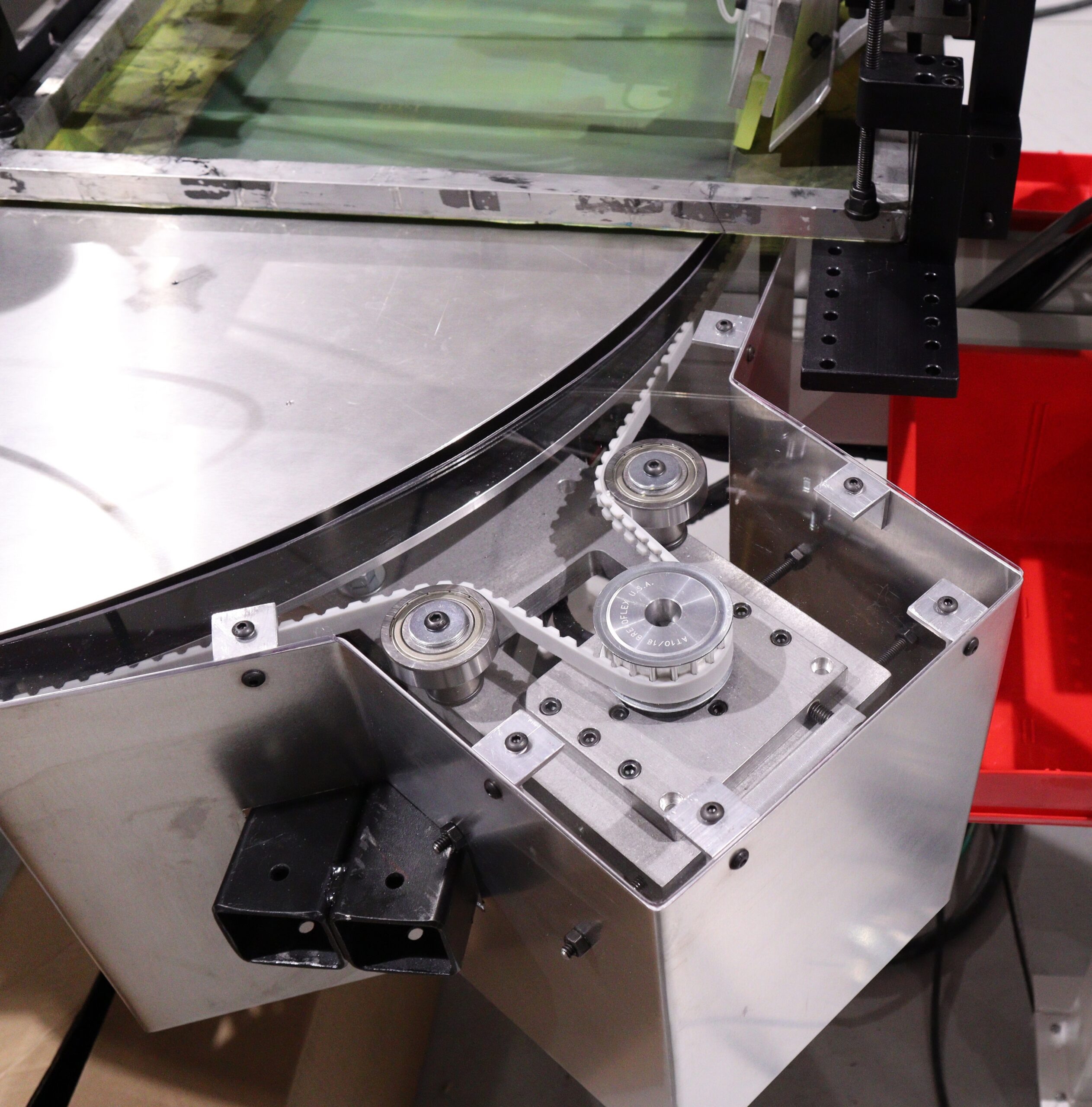

- Hardened, ground, and polished shafts with linear ball bearings rated at over 300 million cycles.

- Smooth acceleration and deceleration of dial motion.

- All Mechanical Geneva indexer.

- Easy to service.

- Variable print stroke length.

- Universal screen mounting.

- Easily removable squeegee/flood bar assembly.

- Smooth, quiet operation.

- Carriage opens pneumatically for screen cleaning and set up.

- Hinged rear screen frame holder to provide quick access to screen, squeegee and flood bar.

- Doweled nesting plates for quick changeover.

- Machine can operate in single cycle or fully automatic mode.

Standard Features

- Remote control panel with variable speed controls.

- Emergency stop button–releases and exhausts all power to the system.

- Stainless steel air cylinders.

- Single-cycle push button for set up.

- X-Y screen frame micro adjust.

- Heavy duty welded base.

- Foot pedal cycle start.

- Rake type take-off device.

- Front carriage interlock.

- 32″ 8-position dial.

- Changeable indexing, can easily be changed to 4, 6, 8, 12 or 24 stations.

Options

- Dial indicators for screen frame holder micro adjust.

- Vacuum table aircraft aluminum honeycomb construction guaranteed flat within +/- .001” (.025mm).

- Retracting stop pins for vacuum table.

- Dual print head for precise squeegee pressure for images 16”(406mm) or wider.

- Adjustable squeegee angle.

- Two dial indicators mounted to the X, Y screen frame micro adjust table.

- Take off device.

- Stacking conveyor for take-off accumulation.

- Vacuum systems for securing products.

- Regenerative ½ hp vacuum pump.

- Extra station on indexer dial.

- Additional indexing dial.