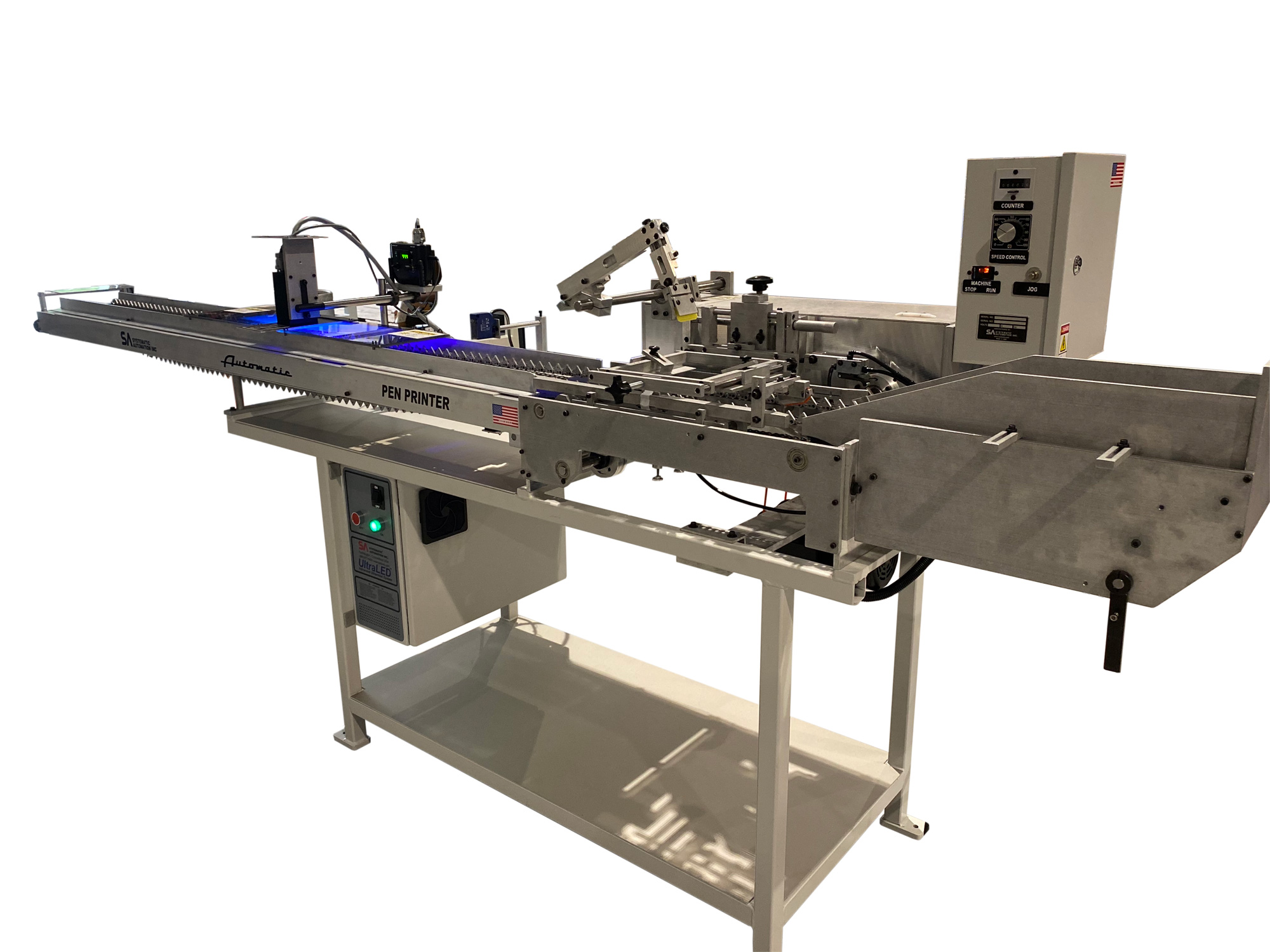

PEN Screen Printing Machine

- Print approximately 4,200 pens per hour.

- Rated for continuous duty, 3 shifts per day, 7 days a week.

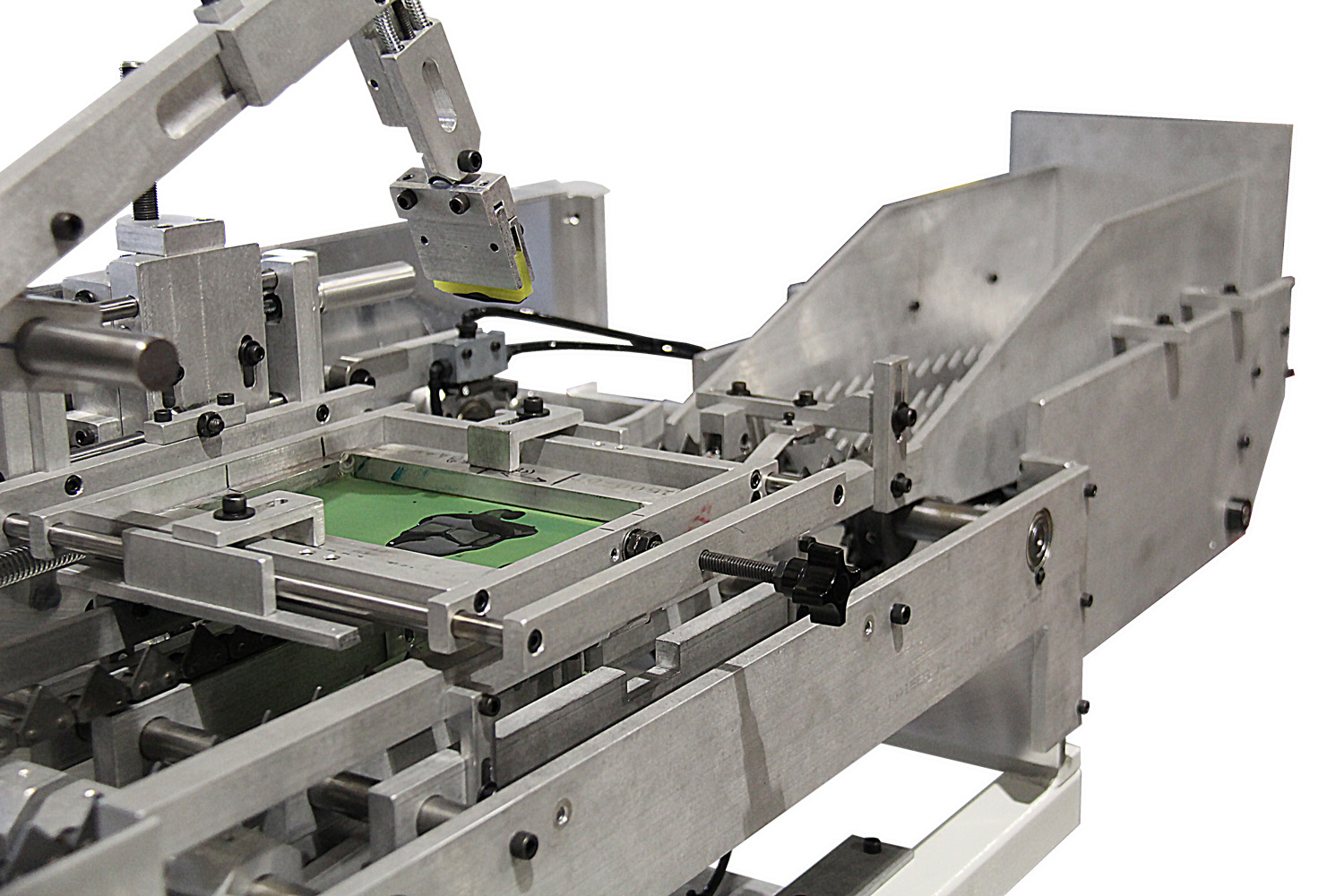

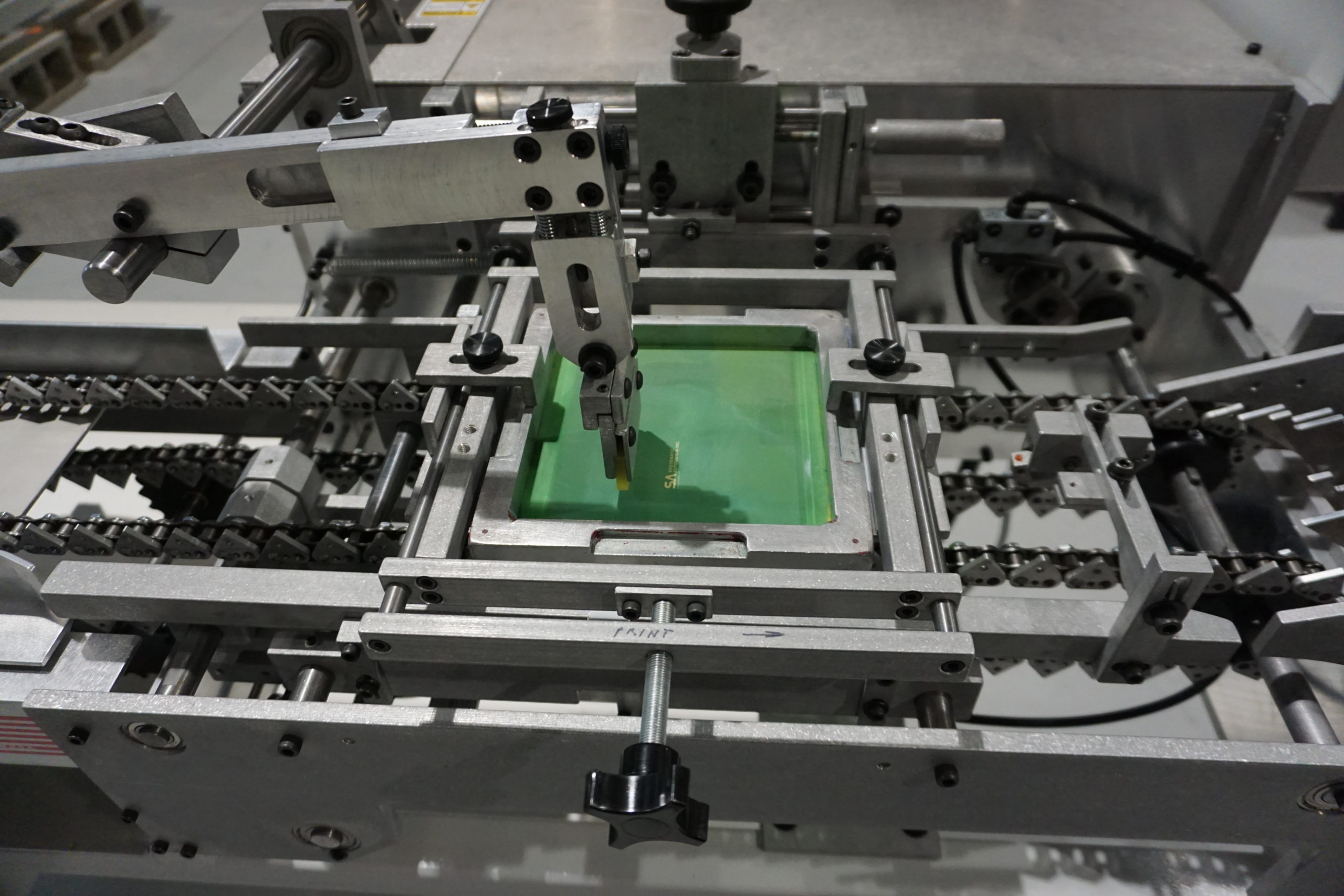

- Modular printer design permits a variety of pen designs.

- Quick changeover between products.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Product Description

Screen Printing Your Pens Has Never Been So Simple

• Automated Pen Printing: The PEN Screen Printer is the perfect solution for automatically printing your entire pen catalogue with user-friendly operation.

• Modular Design: Add optional features like pretreatment, curing systems, and auto-load/unload systems. Expand to multi-color printing with optical or mechanical registration based on your needs.

•High-Speed Production: Capable of printing approximately 4,200 pens per hour, boosting your production rate while reducing labor costs.

•Built for Reliability: Designed for continuous operation (3 shifts per day, 7 days a week), the PEN Printer delivers decades of dependability with high-speed mechanical motion and operator-friendly controls.

•Versatility for Pen Sizes: The design accommodates a variety of pen sizes and shapes, with optional hot air dryer and LED integration.

•Made in the USA: The PEN Printer is engineered and manufactured in the USA, rigorously tested for quality, and backed by immediate support for all your pen printing needs.

About

• Versatile Pen Printing: Screen printing is the most efficient method for printing on virtually any pen size or shape, making it ideal for large quantities. It can print on the entire circumference, handle multi-color prints, and offers quick drying times.

• Compatible with Different Materials: Unlike other methods, screen printing works on various pen materials, including plastic, metal, and wood.

• UV/LED Dry Ink vs. Air-Dry: UV/LED ink is recommended for its instant drying capability, while air-dry ink requires longer drying times and more conveyor space to maintain production speed.

•Adjustable for Complex Pen Designs: Pens with caps, clips, or round designs can be adjusted for precise printing using mechanical or optical registration systems, ensuring accurate multi-color prints.

•Efficient and Cost-Effective: Screen printing remains the top choice over pad, foil, digital printing, or engraving due to its superior speed, opacity, and cost-efficiency.

Pretreatment

• Enhance Ink Adhesion with Pretreatment: Flame pretreatment is essential for removing oil contaminants and improving surface tension on bulk products, ensuring better ink adhesion.

• Custom Flame Systems: A burner is integrated into your machine to provide flame coverage across the entire surface, whether cylindrical (360-degree rotation) or flat.

• In-House Manufacturing: Burners are custom-made in-house to fit your product’s specific size, providing thorough pretreatment before printing.

• Effective Surface Preparation: Pretreatment ensures your product is properly prepared, leading to optimal print results.