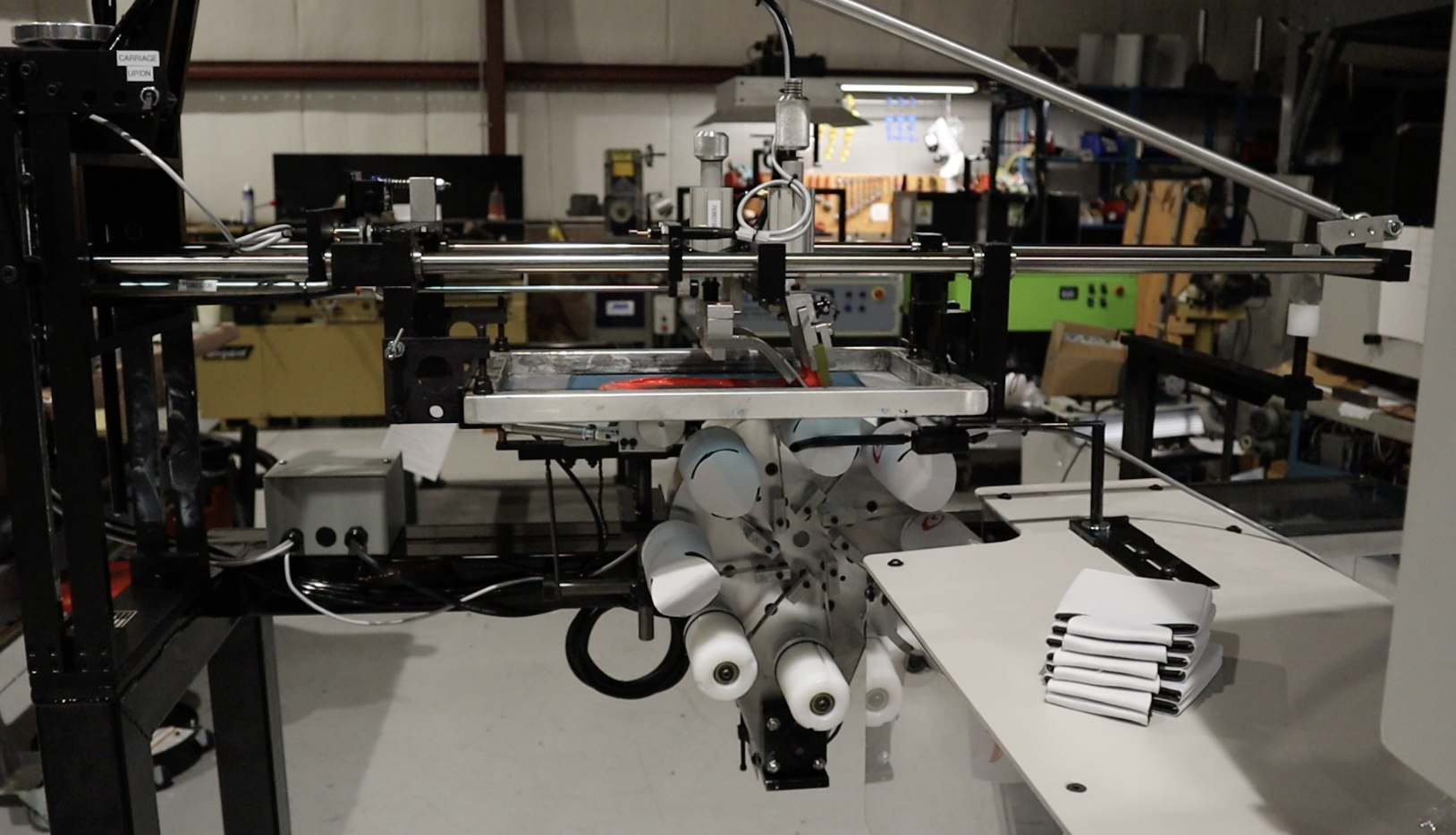

Koozie Screen Printing Machine

- Koozie printing simplified.

- Approximately 3,600 prints per hour.

- Full 360 degree print area

- 8 station servo indexer.

- Automatic take off into dryer.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Koozie Printing

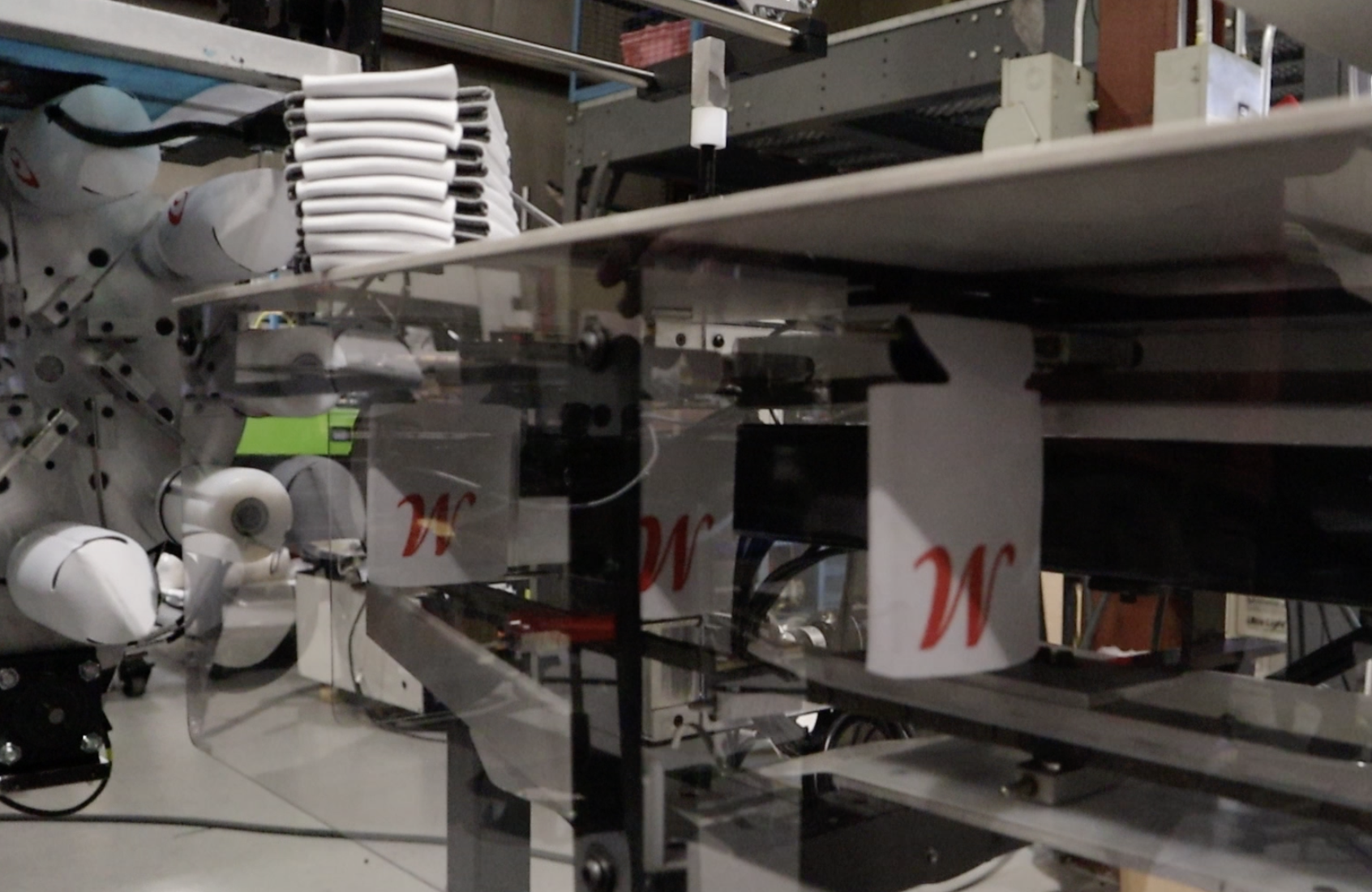

Efficient, Dual-Sided Printing in One Operation

• High-Speed Production: Eight-station rotary indexer enables rapid, dual-sided printing on foam or neoprene koozies, halving print time compared to traditional systems.

• Automated Unloading: Servo-driven unloader removes koozies from the print area, ensuring a smooth workflow.

• Energy-Saving Drying: Features a compact, electric dryer designed specifically for koozies, maximizing energy efficiency and cutting costs.

• Quality and Brand Impact: The industry-standard solution for producing high-quality koozies to keep drinks cold and boost brand visibility.

Streamline your Koozie production with the ultimate in automated, efficient, and cost-saving screen printing technology.

Features

Screen Printing Koozie Features

- Precision machine tool quality and durability.

- Operator friendly controls.

- 8 station servo indexer is standard.

- Auto-take off into dryer.

- 100% air operation (safer for use near flammable solvents).

- Pneumatic systems cannot overload or burn out.

- Smooth, quiet operation.

- Hardened ground and polished shafts, top quality linear ball bearings rated at over 300 million cycles.

- Open design keeps ink vapors from collecting or being directed toward operator.

- Universal screen mount.

- Quick release squeegee assembly.

- Flood bar rises and falls alternately with squeegee.

- Carriage opens pneumatically for screen cleaning and set up.

- Precision hinged rear screen frame holder provides access to inside of screen and squeegee without affecting registration.

- A timer to shut off the heater if the conveyor has not been run for a designated time period.

- A sensor and electronic counter to count the can coolers as they fall from the dryer unloader.

- A smoke detector mounted on top of the dryer. The smoke detector will make an audible signal if smoke is detected and will automatically shut off the heater.

Standard Features

- Unloader to put can coolers onto dryer.

- Adjustable drag for mandrels.

- Servo-indexing hot air can cooler dryer for plastisol inks.

- Control Panel.

- Emergency stop.

- Adjustable operating speed.

- Adjustable print speed.

- Adjustable flood speed.

- Adjustable squeegee pressure with gauge and regulator.

- Single cycle/automatic cycle.

- Print-flood/flood-print switch.

- Carriage up/down.

- Variable indexer speed.

- Squeegee holder.

- Heavy-duty welded steel base with casters and tote bins.

- Stroke counter.

- Foot pedal cycle start.

Koozie Printer Options

- Laser pointer for registration.

- Automatic orientation of the mandrel.

- Servo driven indexer (US patent #5,784,932) replaces pneumatic indexer for printer.

- Automatic Ink Dispenser.

- Part present detect.