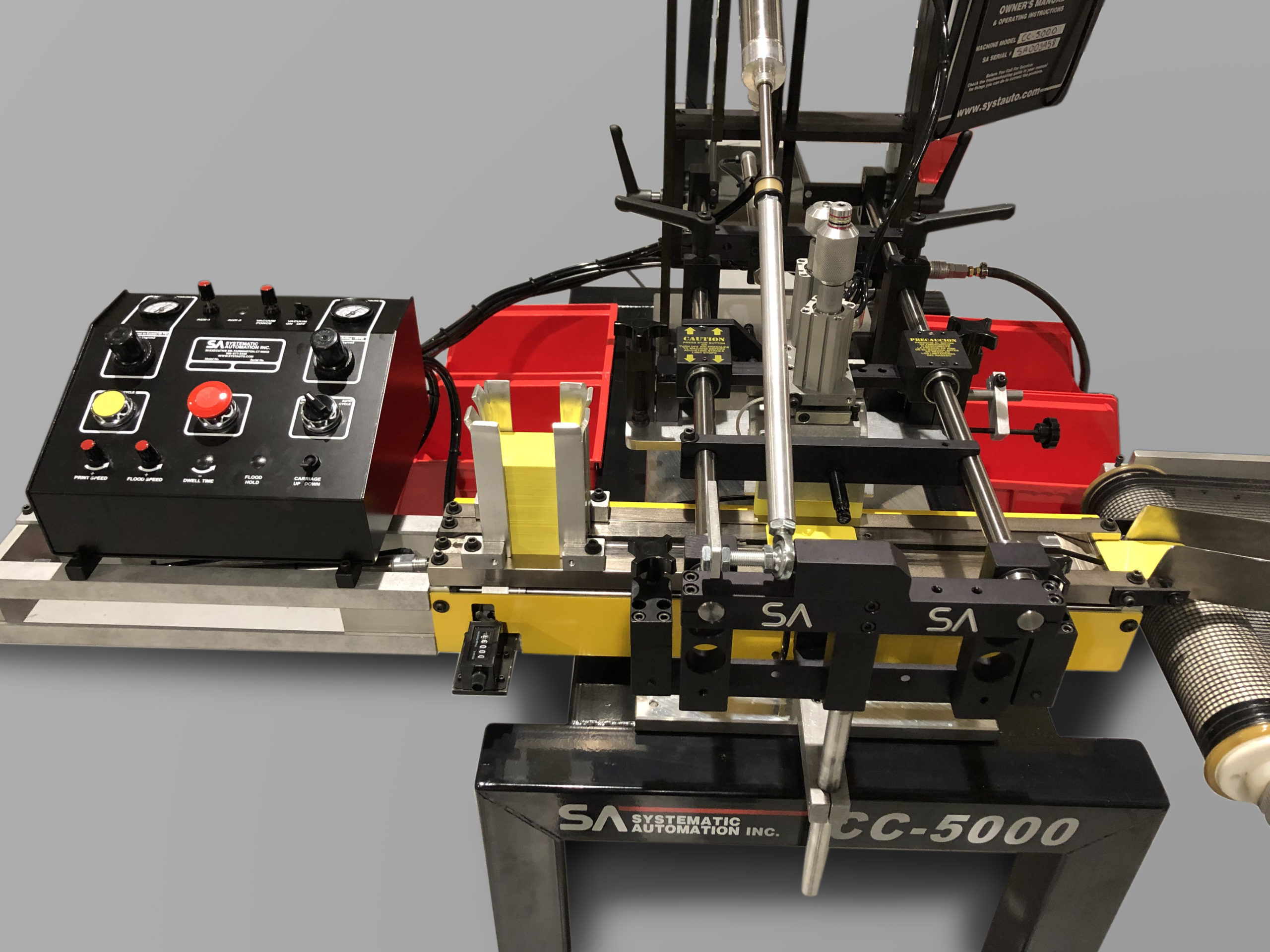

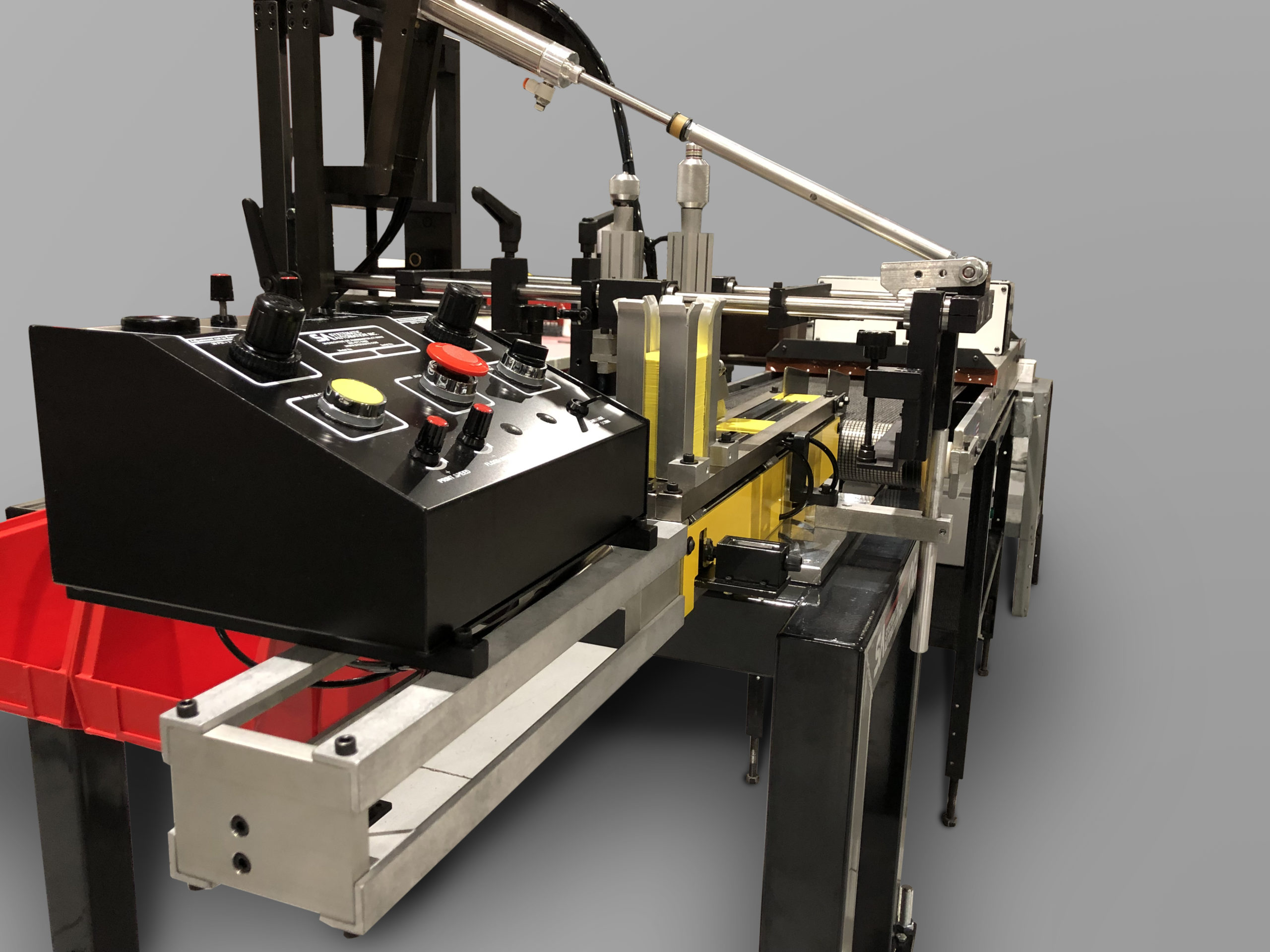

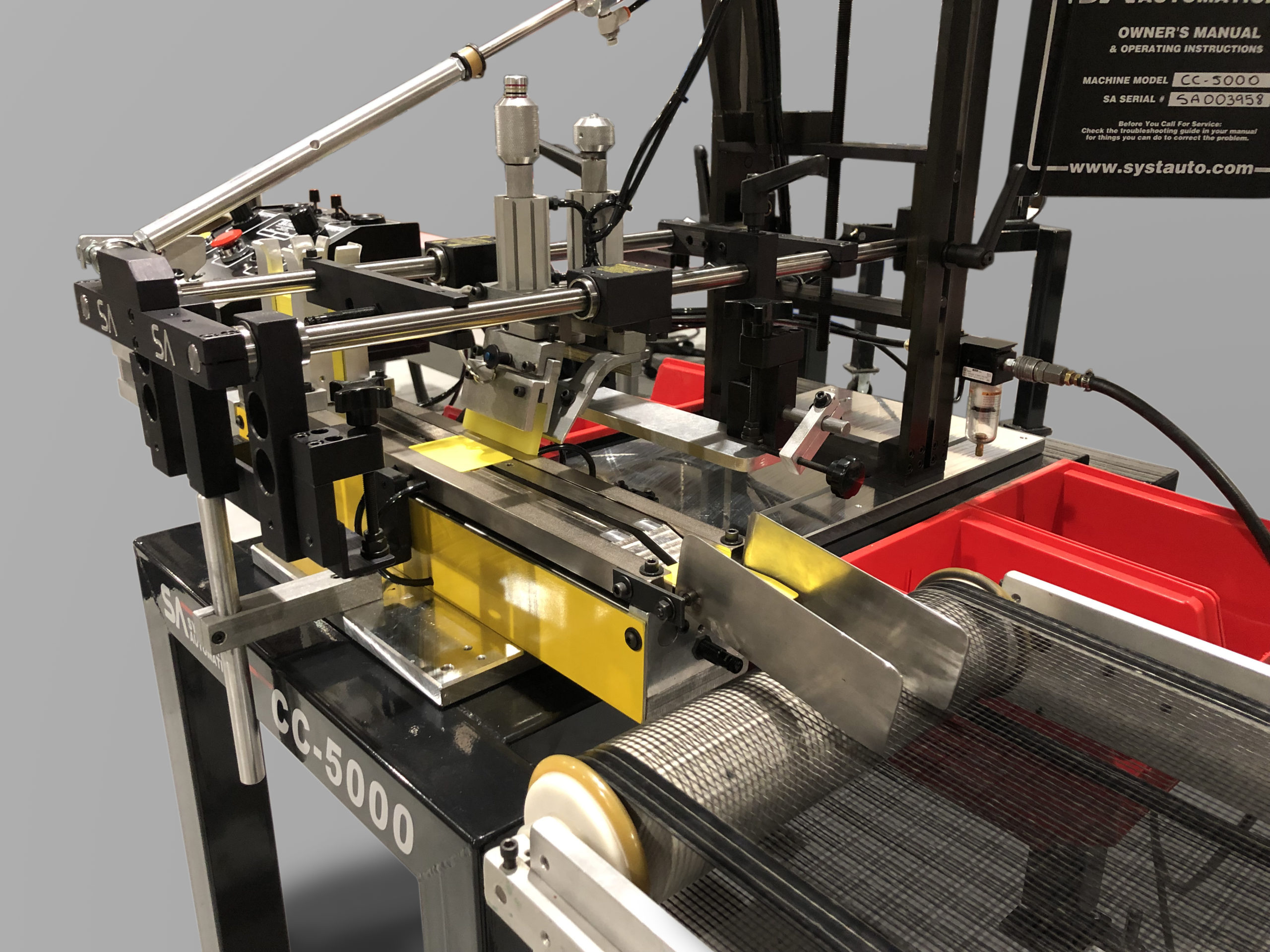

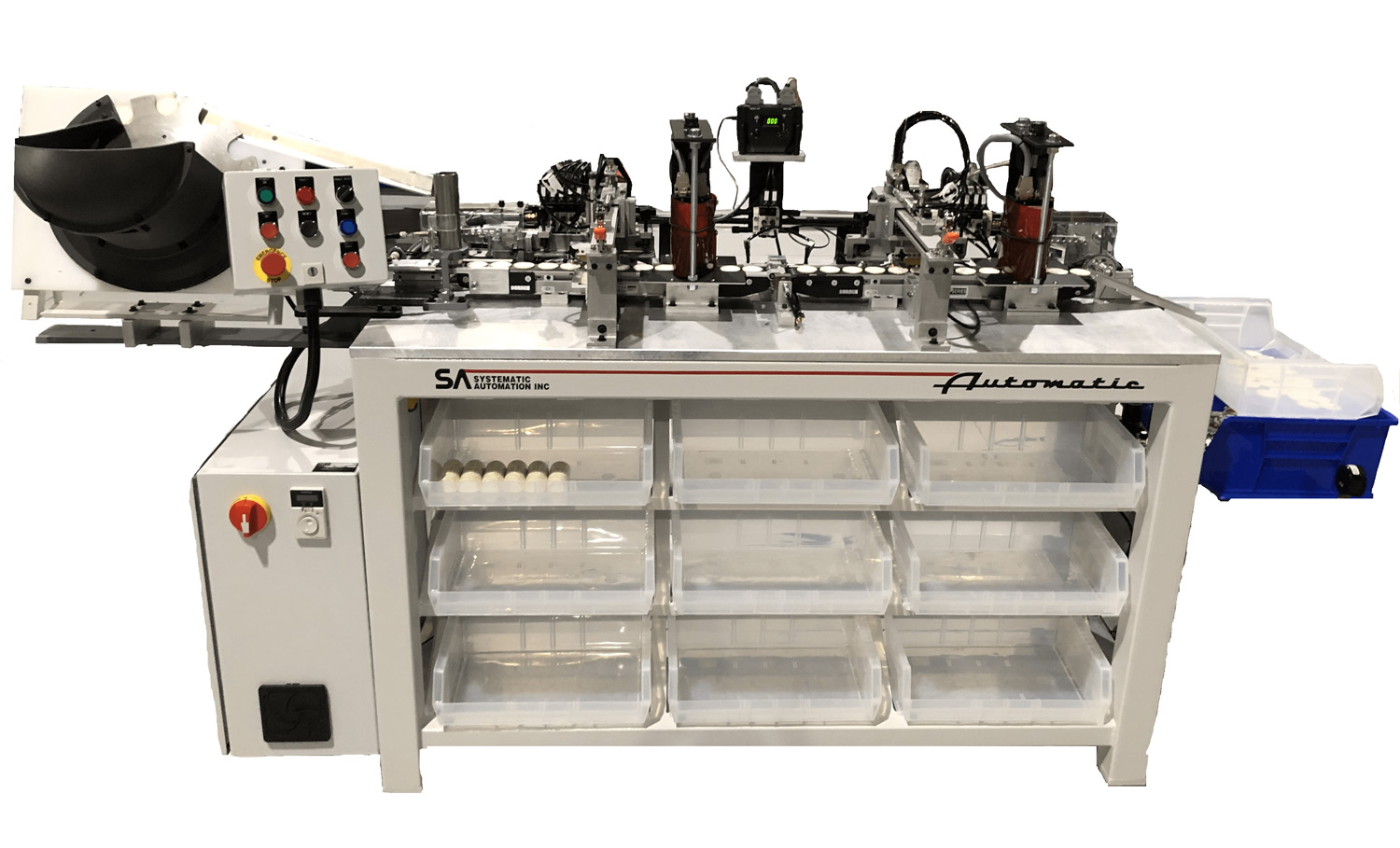

CC-5000 Screen Printing Machine

- Ideal for cards, poker chips, tokens, nail files and more.

- Approximately 5,000 prints per hour.

- Top quality linear ball bearings rated at over 300 million cycles.

- Pneumatic system cannot overload, burn out or become obsolete.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Product Description

Engineered for Efficiency, Built to Last

English Data Sheet | Spanish Data Sheet

• Superior Durability: Constructed with high-grade materials and minimal moving parts, ensuring a reliable, low-maintenance investment.

• Quick Setup & Changeover: X-Y and rotational micro-adjustment for precise screen-to-part alignment. Flip a switch to open the entire carriage, accessing the screen’s bottom easily.

• Effortless Adjustment: Adjust screen-to-part off-contact distance with a top-mounted handwheel, enhancing print consistency.

• Seamless Inspection: Parts are held for 1/2 second on an open feeder for in-process visual inspection, with optional automated optical inspection available.

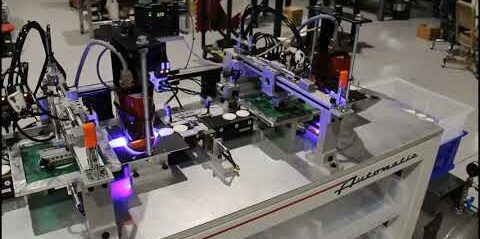

• Enhanced Functionality: Integrate anti-static and flame pretreatment, loaders/unloaders, vision inspection, product detection, and an automatic ink dispenser for added versatility.

Choose the CC-5000 for high-quality, efficient card printing that’s built to keep your production smooth and your investment secure.

Features

Engineering Features

- Precision machine tool quality and durability.

- Stainless steel air cylinders.

- Adjustment for varying product widths and thicknesses.

- Hardened, ground and polished shafts, top quality linear ball bearings rated at over 300 million cycles.

- Simple, reliable air logic controls.

- 100% air operation.

- Pneumatic system cannot overload, burn out or become obsolete.

- Universal screen mount.

- Easily removable squeegee/flood bar assembly.

- Flood bar rises and falls alternately with squeegee.

- Hardened steel, feed fingers.

- Smooth, quiet operation.

- Carriage opens pneumatically for screen cleaning and set up.

- Worldwide component parts availability.

Standard Features

- Adjustable print stroke speed.

- Adjustable flood stroke speed.

- Variable stroke length.

- Machine designed to accommodate pre-treat and anti-static, or clean wipe stations.

- Six-digit reset counter.

- Pneumatic control panel.

- Emergency stop.

- Machine leveling feet.

- Single-cycle push button for set up.

- Vacuum pump (4.5 cfm).

Pretreatment

Your product surface may require pretreatment to promote ink adhesion. Products ordered in bulk may have oil contaminants or other residue as well as having poor surface tension, which can be remedied by flame pretreatment. Pretreatment integration is done by installing a burner on your machine that will provide flame to your entire surface area. If your product is cylindrical, it will spin 360 degrees, parallel with the burner and if it is flat, the flame system will move to cover your product area. Burners are made in house and to size. Pretreatment is done prior to printing your product.