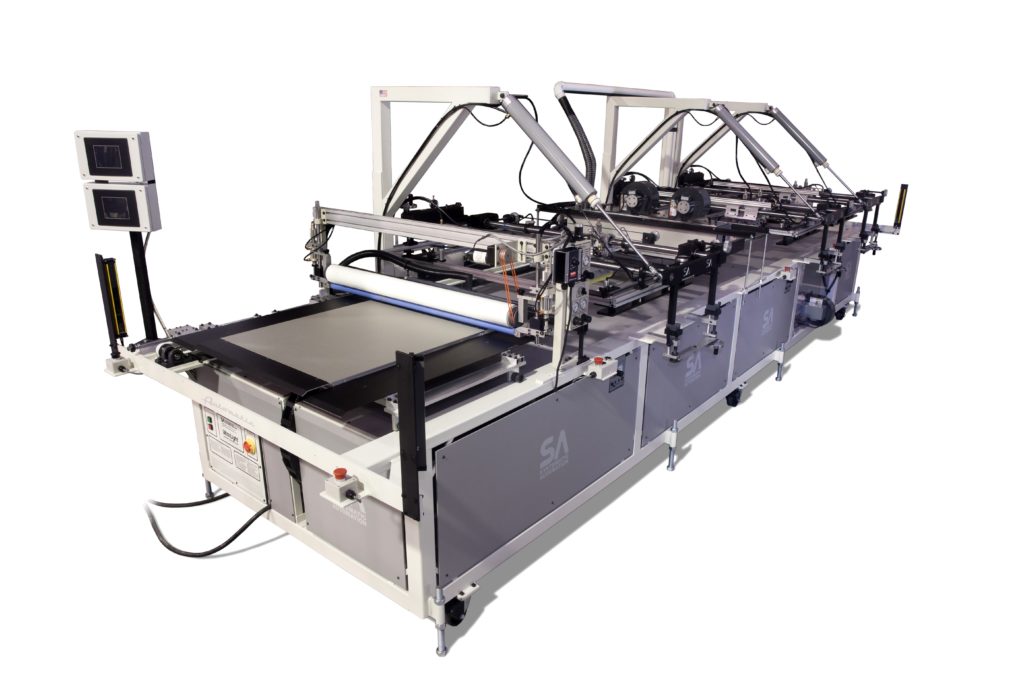

Microscope Slide Screen Printing Machine

- Approximately 3,600 prints per hour.

- Glass chipping is nearly 100% eliminated.

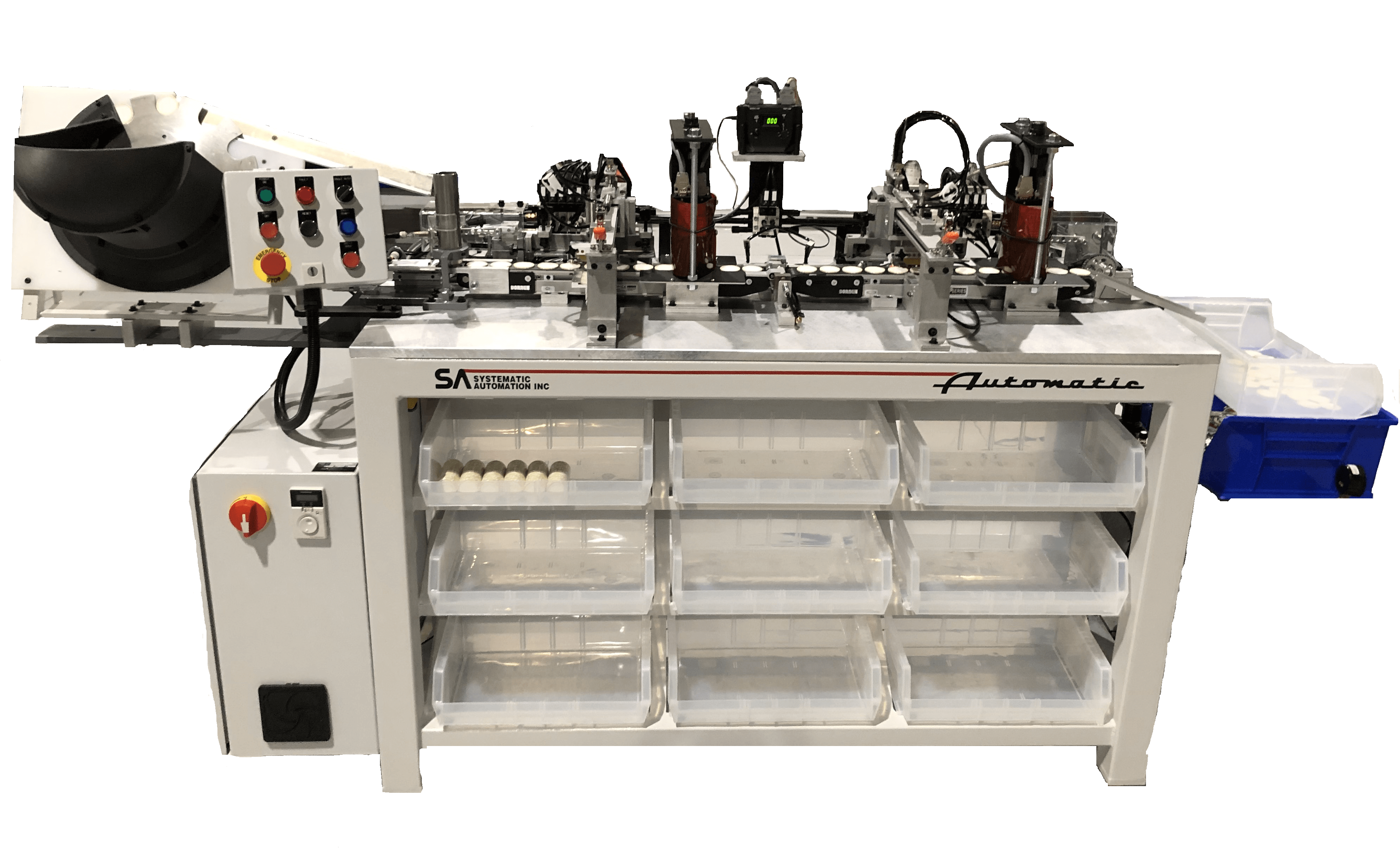

- Automatic loader including load magazines and pick & place.

- 2-axis automatic unload robot including unload slide gripper.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Product Description

Automated, High-Precision Slide Printing for Medical Labs

• Automatic, High-Speed Production: Handles up to 1,080 slides per hour with exact order quantities, ensuring high productivity for any lab size.

• Precision Engineering: Offers repeatability within +/- .003” (0.07mm), ideal for consistent results. Developed alongside the leading U.S. medical supplier and built to last.

• Hydrophobic Ink Compatibility: Works seamlessly with Cytonix MH-ink, available in translucent and pigmented options, to retain samples securely on the slide.

• Customizable Process Control: Optional integrated pick-and-place function for oven curing, vision inspection for quality control, and dual-stack automatic loading.

• Additional Automation Options: Anti-static features, automatic ink dispensing, and full support for further process integration.

Manufactured in the USA since 1983, this rugged, reliable Microscope Slide Printer is your essential solution for efficient, precise lab operations.

Features

Engineering Features

- Machine tool quality and durability.

- U.S. Patent # 5,784,932.

- Prints frosted or unfrosted microscope slides.

- Break away safely features throughout to protect operator and machine.

- Linear bearings throughout rated at over 300 million cycles.

- Servo motor overload protection.

- Rear screen frame holder is precision hinged providing quick access to inside of screen and squeegee.

- Easily removable squeegee/flood bar assembly.

- Flood bar rises and falls alternately with squeegee.

- Smooth quiet operation.

- Each component is modular for simplicity of design and serviceability.

- Oversize slides are automatically detected.

- Hardened tool steel slide escapement.

- Glass chipping is nearly 100% eliminated.

- Machine can be loaded with slides as it is running.

- All rugged PLC machine control.

- Welded steel machine base. Powder coated.

- Mechanical dripping and vacuum holding of slide in nest.

- Machine makes no contact with top of slide.

- Slides are gripped from the sides only.

- Common exhaust and oil free cylinders for pneumatic eliminates contamination.

- Large in-feed magazine capacity.

Standard Features

- Non-contact vacuum on top of slide for cleaning prior to printing.

- Pre-cleaning vacuum on nest prior to loading.

- Variable print and flood speed control.

- Variable squeegee pressure with gauge.

- X, Y and angular screen frame micro adjust with dial indicators.

- Foot pedal cycle start for set up.

- Resettable counter.

- Manual load feature for non standard slides.

- Adjustable squeegee angle.

- Micro adjustment of flood bar parallelism to screen.

- Slide part present detect. omits print stroke.

Pretreatment

Your product surface may require pretreatment to promote ink adhesion. Products ordered in bulk may have oil contaminants or other residue as well as having poor surface tension, which can be remedied by flame pretreatment. Pretreatment integration is done by installing a burner on your machine that will provide flame to your entire surface area. If your product is cylindrical, it will spin 360 degrees, parallel with the burner and if it is flat, the flame system will move to cover your product area. Burners are made in house and to size. Pretreatment is done prior to printing your product.

Related products