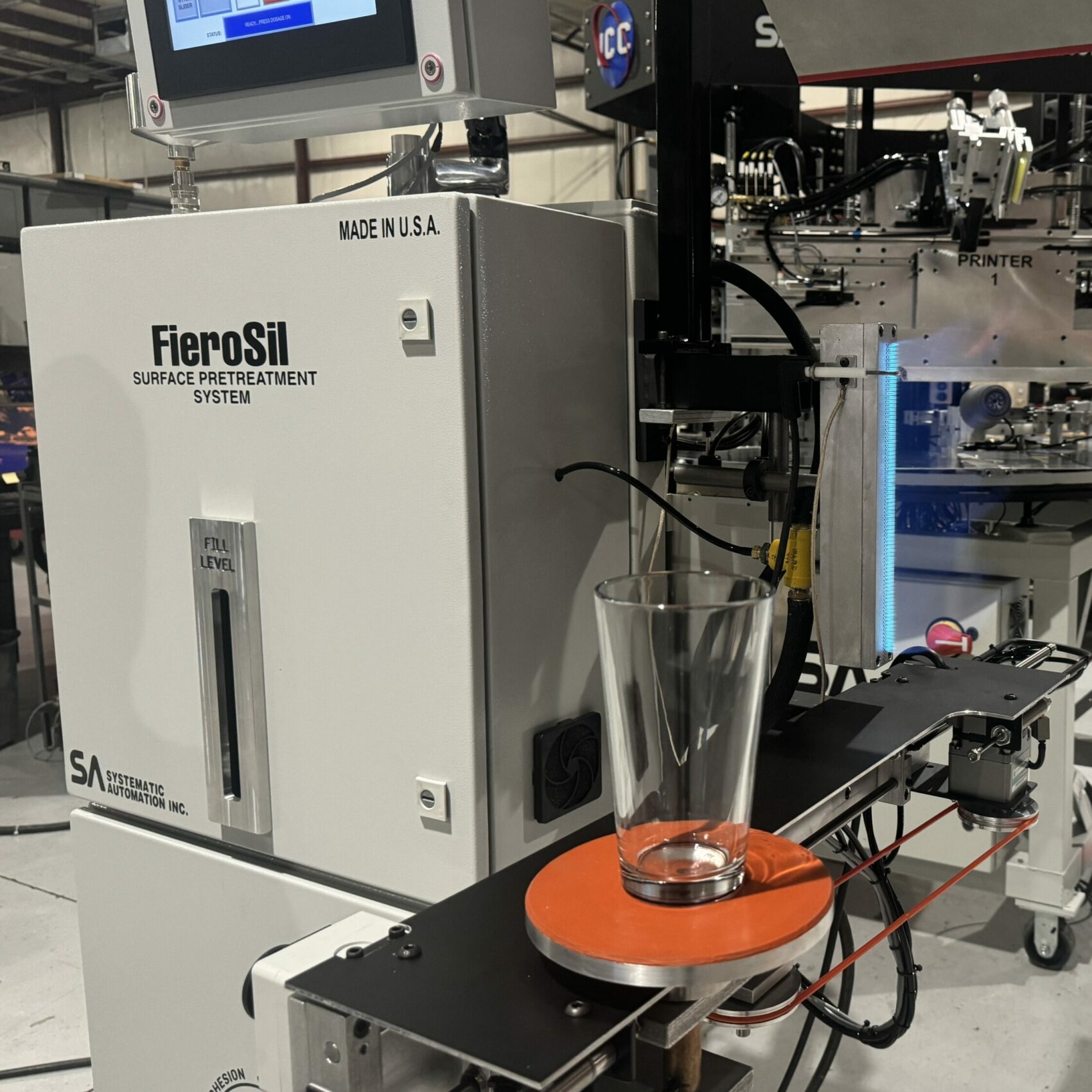

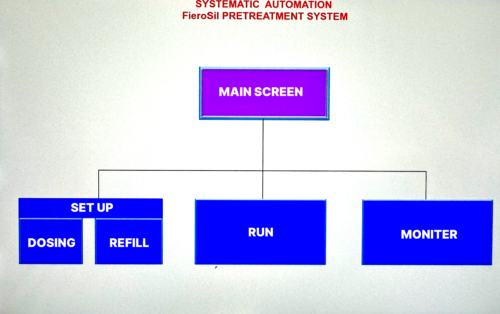

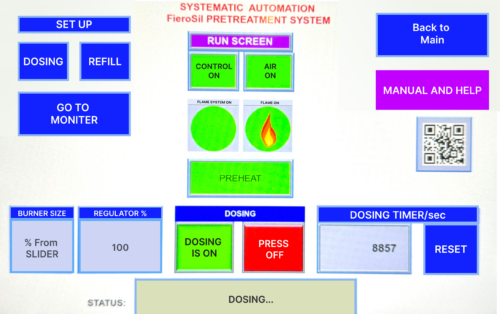

Fierosil Pretreatment system

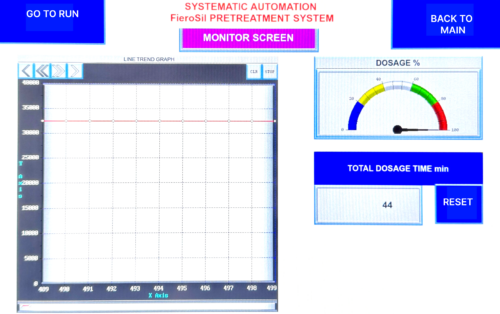

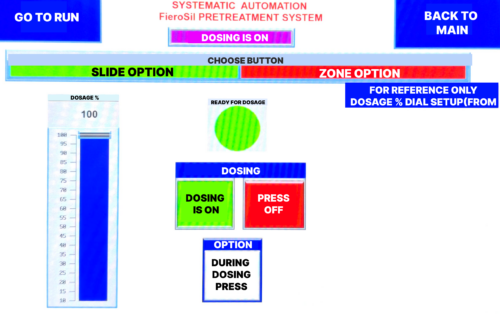

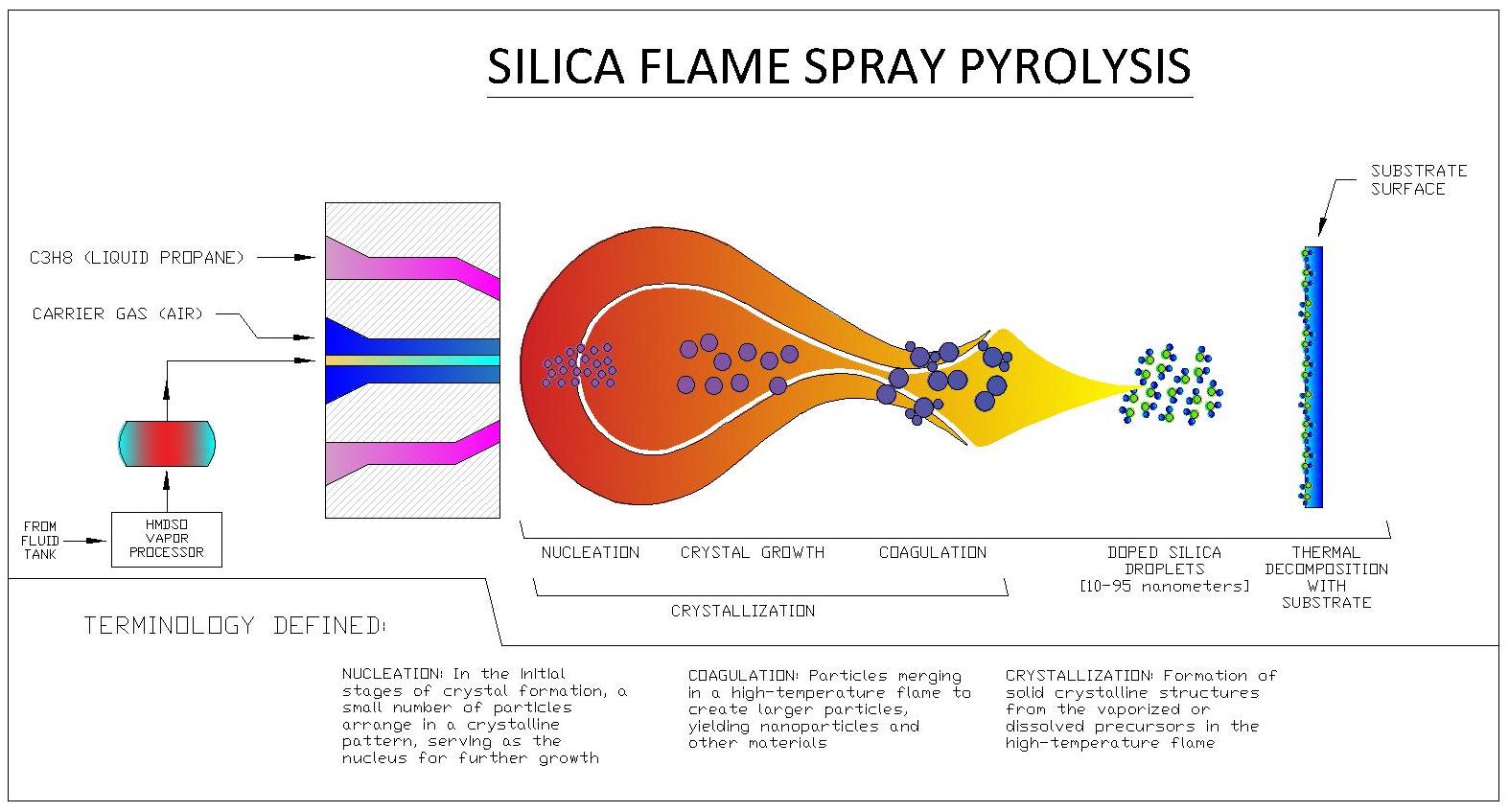

• Proven Technology: The FieroSil system utilizes vapor deposition with Hexamethyldisiloxane (HMDSO), a technology used in industrial applications since the 1950s and widely adopted by the semiconductor industry.

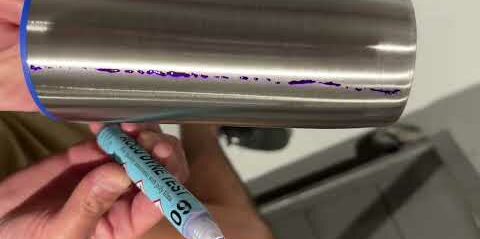

• Enhanced Surface Tension: The silica particles fuse to the substrate, creating a fine, sandpaper-like surface that improves ink adhesion without affecting the material’s clarity.

• Improved Printing Quality: Proper surface preparation with FieroSil ensures no smudging, bleeding, or peeling, resulting in higher quality screen printing.

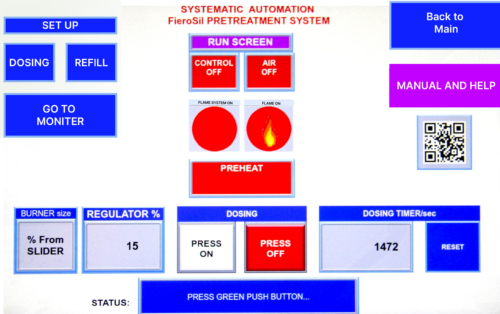

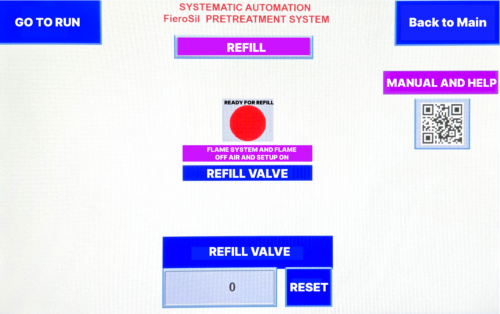

• Pre-Engineered Solutions: Customizable and pre-engineered solutions tailored to your product’s needs. The Flame 360 is an 8 station pretreatment system for both FieroSil and flame pretreatment.

• Made in the USA: FieroSil is manufactured and packaged domestically at SA headquarters and is available for immediate shipment.

Speak today with a specialist on how we can bring the FieroSil to your shop floor.

CUSTOM Solutions Available

• In-House Manufacturing: All manufacturing processes are performed at Systematic Automation’s headquarters in Farmington, CT, ensuring quality control over every aspect of your flame treatment system.

• Custom Features: SA engineers can design and integrate any custom features you need for your system, offering flexibility to meet your specific requirements.

• Proven Material Handling Solutions: Proven solutions are available for material handling, and can be tailored to create a complete turnkey system for automatic pretreatment.

•40+ Years of Expertise: With over 40 years of engineering and manufacturing experience, we offer reliable, tailored solutions for flame treatment systems.

Testimonial

I inspect all orders, and I pay special attention to the beer growlers because UV ink does not want to stick onto the glass beer growlers, the reason is because the glass is so low end and crappy, ink just does not want to stick…. Then I ask my operator how she pre-treated: operator says with the new Fireosil system. I scratch onto the ink, and it’s bulletproof.

- Murray, Buccaneer Inc.