Flame 360 | Flame Treatment Machine

- Ideal for cups, glassware, bottles and more.

- Part flexibility for cylindrical and irregular shaped items.

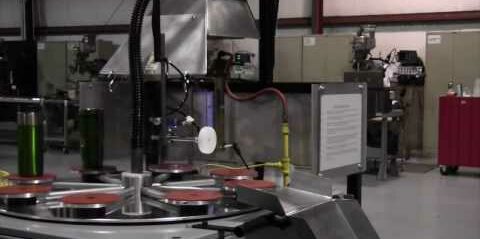

- Geneva indexer provides harmonic dial motion.

- Entire print area is rotated 360 degrees through the flame.

- FieroSil adhesion promoter integration.

SYSTEMS TO SUIT YOUR APPLICATION & BUDGET

Not sure what you’re looking for?

Product Description

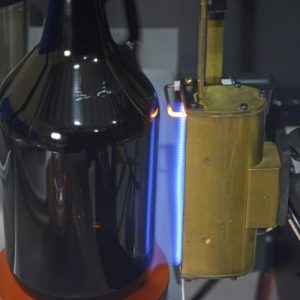

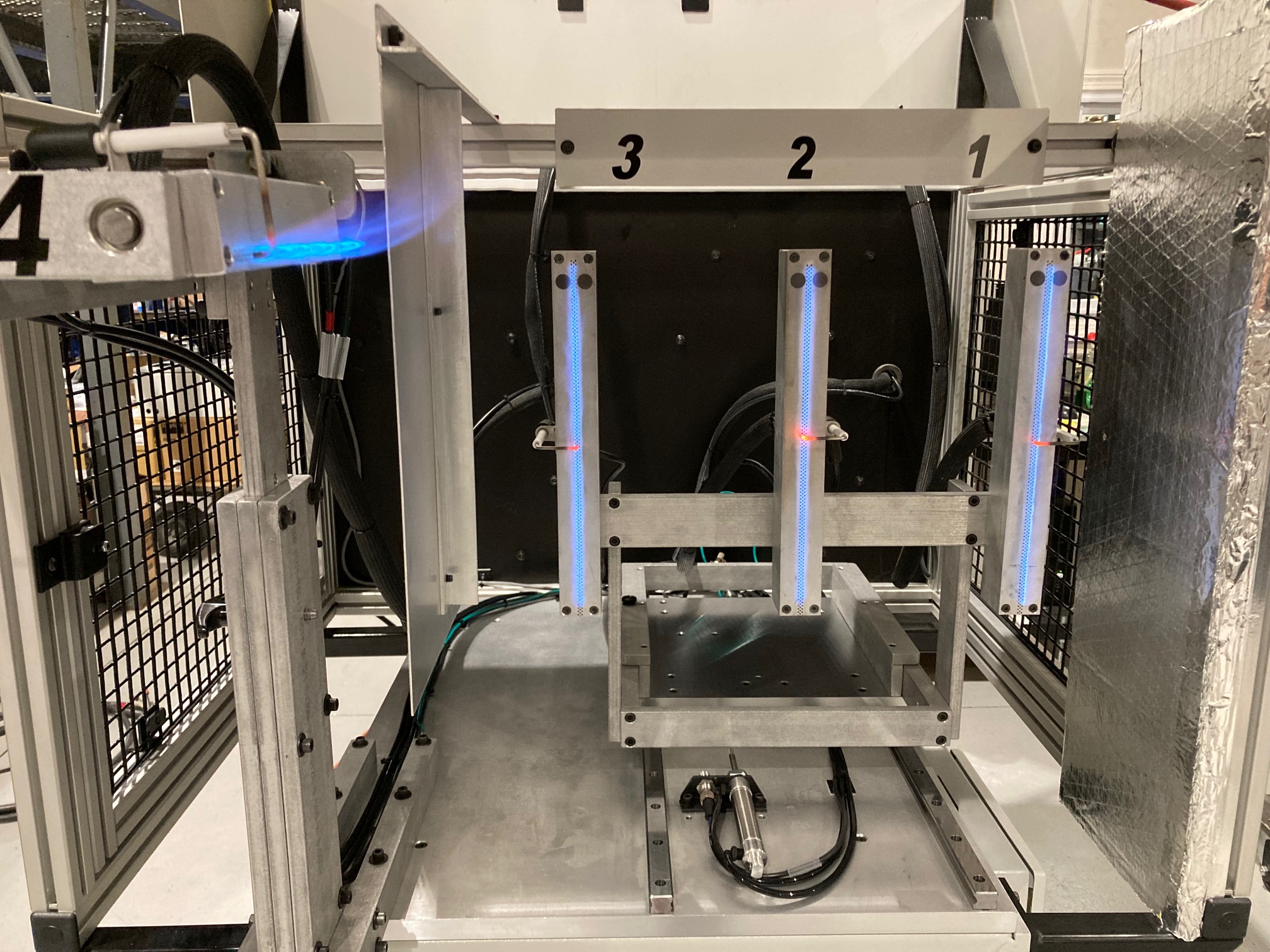

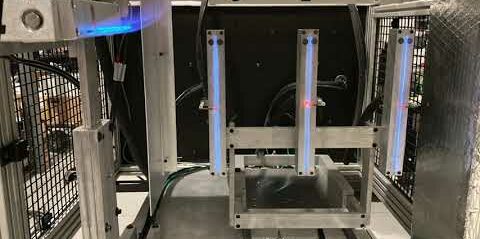

The Flame 360 (U.S. Patent# 6,397,491 B1) is a powerful and versatile flame treatment system designed for fast pretreatment, durability, and continuous use. Burners come in sizes of 6″ (153mm), 10″ (254mm), and 12″ (305mm), with larger options available upon request. The flame height is easily adjustable with a magnetic metal strip for precise control.

Key Features

- Height and angular adjustment for SA burner.

- Universal vacuum plates securely hold most cylindrical products without the need for special holding nests. Dedicated tooling made for odd shaped products.

- Uses an all mechanical Geneva indexer with a brilliantly simple overload clutch. The Geneva indexer provides harmonic (smooth acceleration and deceleration) dial motion.

- Entire print area is rotated 360 degrees through the flame to maximize adhesion. Uniformity of treatment is guaranteed.

FieroSil is available for optimal ink adhesion. FieroSil and flame can both be operational on your pre-treatment system.

Features

Engineering Features

- Part flexibility for cylindrical and irregular shaped items. Sizes from ball point pen barrels to gallon containers.

- Height and angular adjustment for burner.

- Overload clutch.

- Machine control technique entirely eliminates the problem of electrical component obsolescence.

- Geneva indexer provides harmonic (smooth acceleration and deceleration) dial motion.

- Entire print area is rotated 360 degrees through the flame to maximize adhesion. Uniformity of treatment is guaranteed.

- Rotating through the flame allows for the fastest cycling time while ensuring thorough, consistent treating.

- Once parts are loaded, no rollers, belts, or escapements adjust. Changeover from one part to the next can’t get any easier.

- Whether promoting adhesion for UV inks, coatings, or adhesives, the flame treatment system allows adjustment of indexing and rotation speed as well as flame height.

- Compact design.

- Affordable price.

Standard Features

- Incorporates an 8 station Geneva Drive

- Automatic unload – Consists of mechanical eject of parts

- Number of stations – 8

- Adjustable flame burner – 12″ (304 mm)

- Platen diameter – 6″ (152 mm)

- Rotary dial diameter – 32″ (813 mm)

- Input power – 115 VAC

- Fuel – Natural Gas or Propane (please specify at time of order), tank not included

- Exhaust hood

- Compressed air (80 psi) required for automatic unloader

- Heavy duty locking casters

Typical Applications

- Mugs

- Pint Glasses

- Growlers

- Glass Bottles

- Glassware

- Plastic Bottles

- Drinkware

Related products