SCREEN PRINTING YOUR PLASTIC CUPS

Model t8-ss - AUTOMATIC

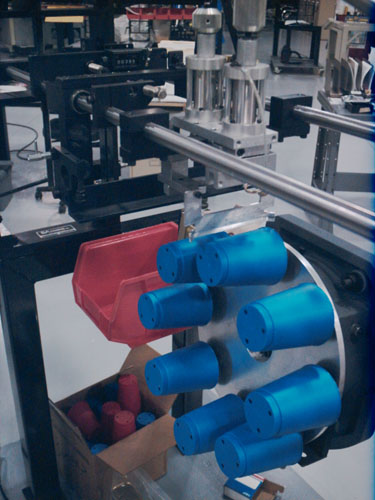

•Industry Standard for Plastic Cup Printing: The Model T8-SS is designed for automatic production of plastic cups, from thin disposable to thick stadium cups.

•Quick and Easy Mandrel Swaps: The machine features easily swappable mandrels for different sized plastic cups, ensuring seamless changeovers.

•Integrated Curing and Take-Off: Comes equipped with a built-in curing system and automatic take-off for efficient, high-speed production.

•Modular Automation Options: Expand your process with additional automation options like pretreatment and automatic loading for a complete turn-key operation.

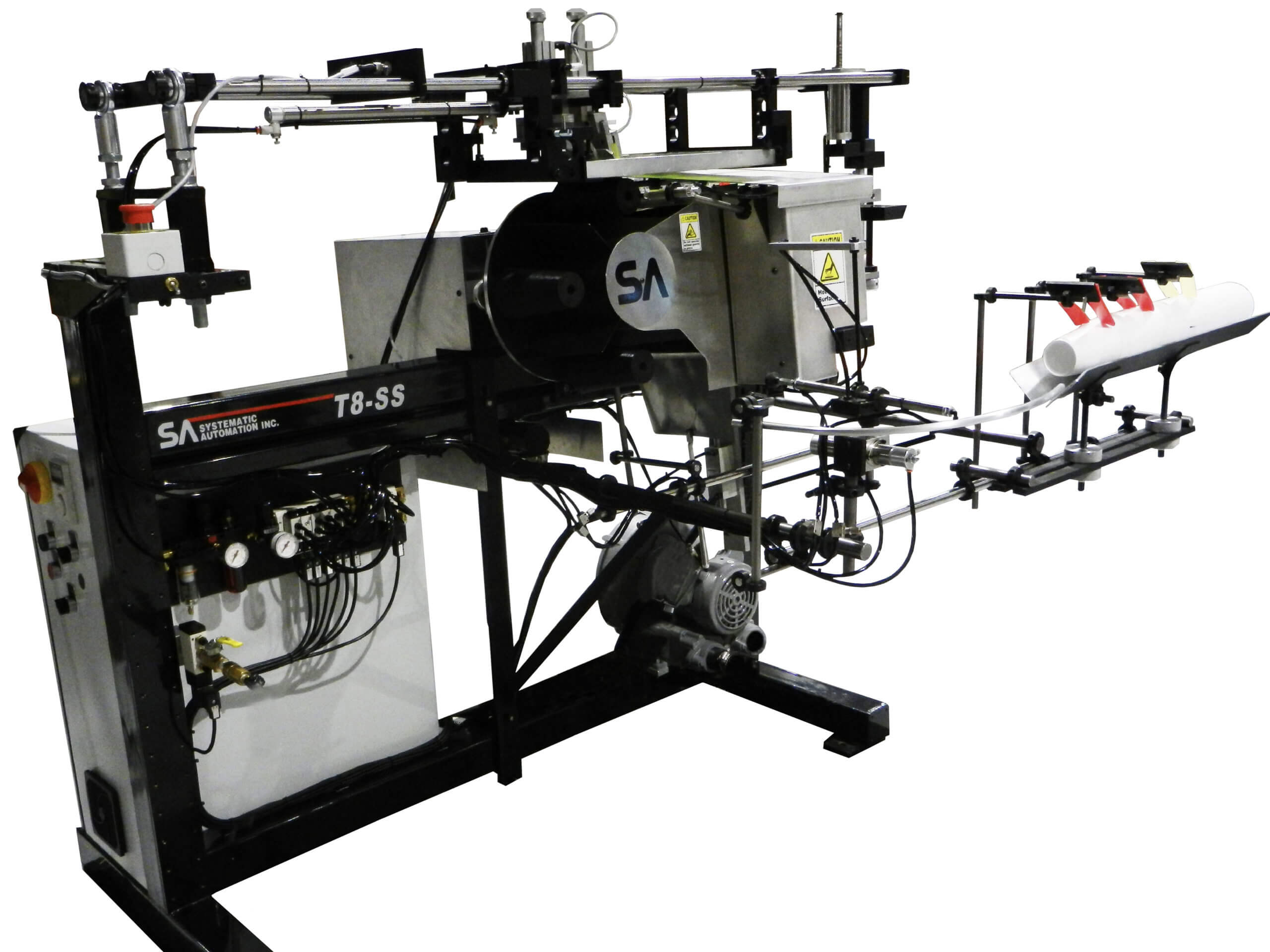

•Versatile Cup Printing: The Model F1-DC is perfect for printing your entire cup catalogue, accommodating all sizes with one machine.

•Precision for Multi-Color Prints: Achieve multiple color prints with precise registration, ensuring high-quality results every time.

•Quick Tooling Changeovers: Tooling for different cup sizes can be swapped in seconds, maximizing efficiency.

•Durable Pneumatic Design: The F1-DC is fully pneumatic, with no electronics to overload or become obsolete, providing a future-proof solution with industry-leading precision.

Model F1-dc - semi Auto

What to know about plastic cups

• Affordable Branding Solution: Plastic cups—whether for home, disposable, or souvenir stadium use—offer an efficient and affordable way for customers to market their brand at events or meetings.

• Ink Choices for Plastic Cups: Choose between UV inks for instant curing (ideal for the T8-SS with integrated UV) or solvent-based inks that can be air dried or expedited with forced air/IR. UV inks provide an instant cure, allowing immediate packaging, while solvent inks require additional drying time.

• Pretreatment Not Always Needed: Pretreatment for ink adhesion is not typically necessary for disposable plastic cups, but may be considered for reusable cups, especially if they are dishwasher safe.

• Model F1-DC for Plastic Cups: The Model F1-DC offers a semi-automatic solution for plastic cup printing. Once printed, cups can be cured with a conveyor oven or the Model UVSP for efficient production.

• Precision Fixtures for Optimal Results: It’s crucial to have fixtures that fit your plastic cups snugly to avoid image distortion during printing. Systematic Automation provides precision manufacturing and test prints to ensure quality before shipping.

• Curing Considerations: For thin disposable cups, avoid forced hot air to prevent warping. UV LED is recommended to mitigate warping risks with conventional UV curing systems, which allow precise control over UV exposure.

Make the Right Choice for Your Screen Printing Business

Systematic Automation is your choice for professional custom screen-printing machines made here in the U.S.A. We offer an array of custom screen-printing machine models to handle all your printing needs. We also offer UV curing machines, vacuum tables, and heat treatment machines to ensure your printing shop can fill every order. We have experienced technicians that offer support to help set up your machine and any technical questions you have once you start printing. Call or contact us today to speak with one of our expert technicians and choose the right machines for your business.

Some of our satisfied customers