Efficient Screen Printing Solutions for Glass Tubes

• Precision for High-Volume Needs: Screen printing on glass tubes requires specialized equipment to ensure accurate, durable prints while minimizing product loss from chipping during the automated process.

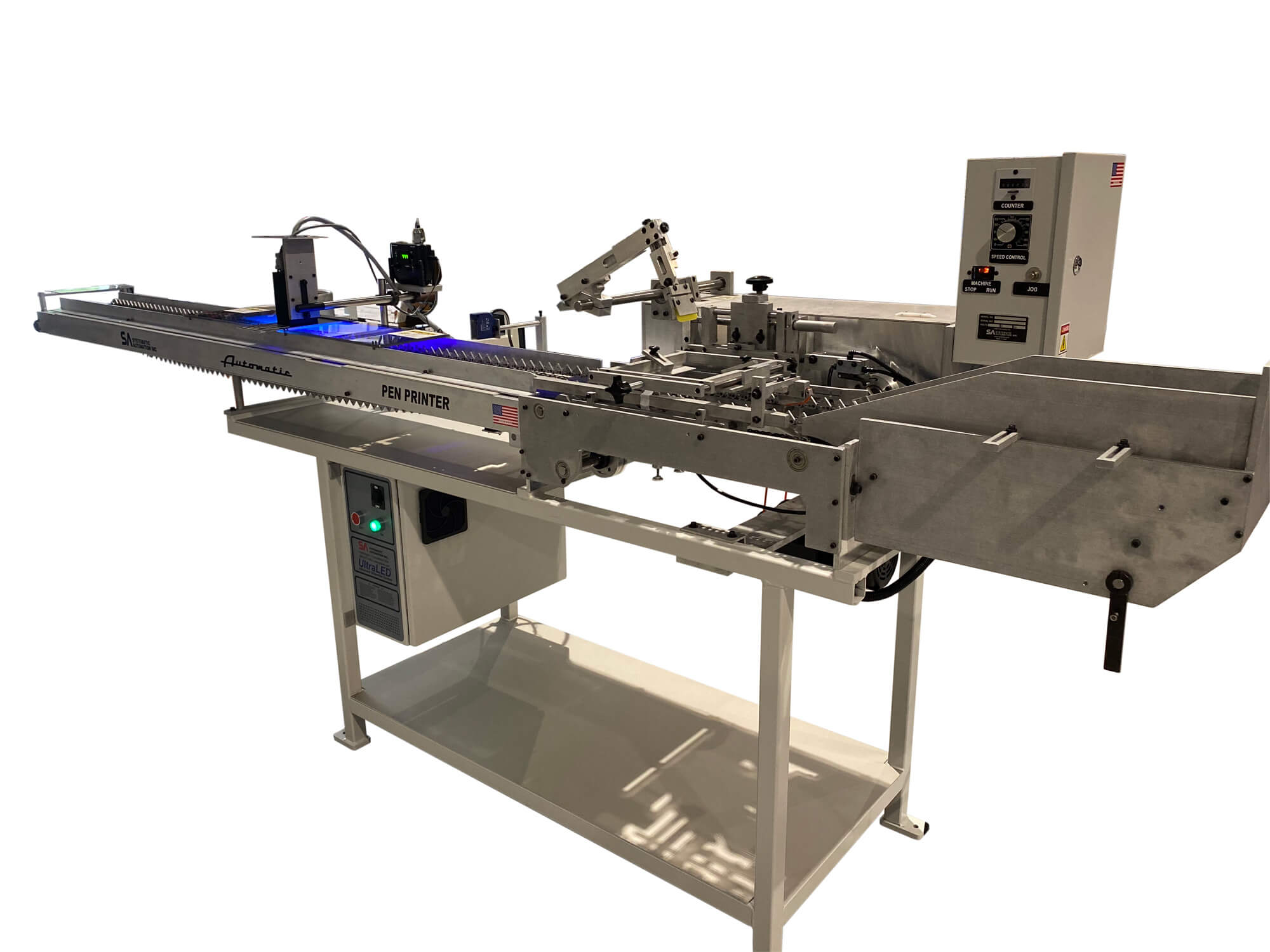

• Fully Automated Workflow: The Model PEN Printer handles the entire printing process, from sorting and feeding glass tubes to printing and curing, requiring only a single operator for loading.

• Customizable Curing Options: Choose from UV, LED, or other preferred curing methods to ensure durable and vibrant prints suited to your specific production requirements.

• Engineered for Glass Tubes: The PEN Printer is specifically optimized for delicate materials like glass, with measures to prevent chipping and ensure consistent, high-quality results.

• In-House Manufacturing Expertise: Designed and manufactured entirely in-house at Systematic Automation’s Farmington, CT headquarters, ensuring superior quality control and tailored solutions.

• Custom Automation Options: Work with our expert engineers to further automate your application, integrating additional features like advanced feeders or inspection systems for enhanced production workflows.

Contact Systematic Automation today to learn how the Model PEN Printer can revolutionize your glass tube printing with unmatched efficiency, precision, and reliability.

The Ultimate Solution for Glass Tube Printing

• Unmatched Production Speed: Achieve high-volume output with up to 4,200 glass tubes printed per hour, streamlining your manufacturing process.

• Customizable Curing Options: Choose from conventional UV, LED, or dryer oven curing, with solvent-based inks in oven curing providing superior adhesion for glass applications. Flame treatment or Fierosil pretreatment can also be integrated for enhanced UV ink adhesion.

• Versatile for Various Tube Sizes: Designed to handle tubes of different diameters with adjustable indexing chains and cradles for quick and precise size transitions.

• Simple Maintenance & Longevity: Mechanical design ensures easy upkeep and troubleshooting, with durable components built to last decades of consistent use.

• Proudly Made in the USA: All components are crafted in our Farmington, CT facility, backed by expert technicians ready to assist with remote or on-site support.

Invest in the Model PEN Printer for fast, reliable, and versatile glass tube printing. Contact Systematic Automation today to learn more!