UltraLight UV Conveyor MAX

- Tri-Power 200/300/400 Watts Per Inch Power Supply

- Programmable Power Supply With PLC

- Adjustable UV Module Distance

- Automatic UV Shutters

- Ideal for Boxes and Cabinets

UV Conveyor For Heavy & Large Products

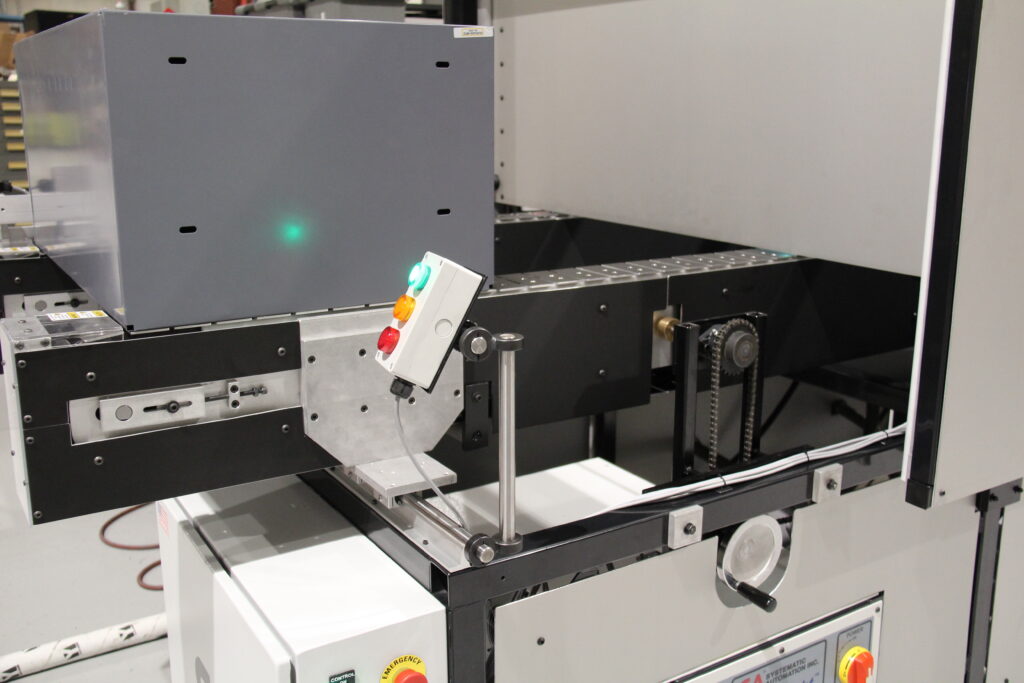

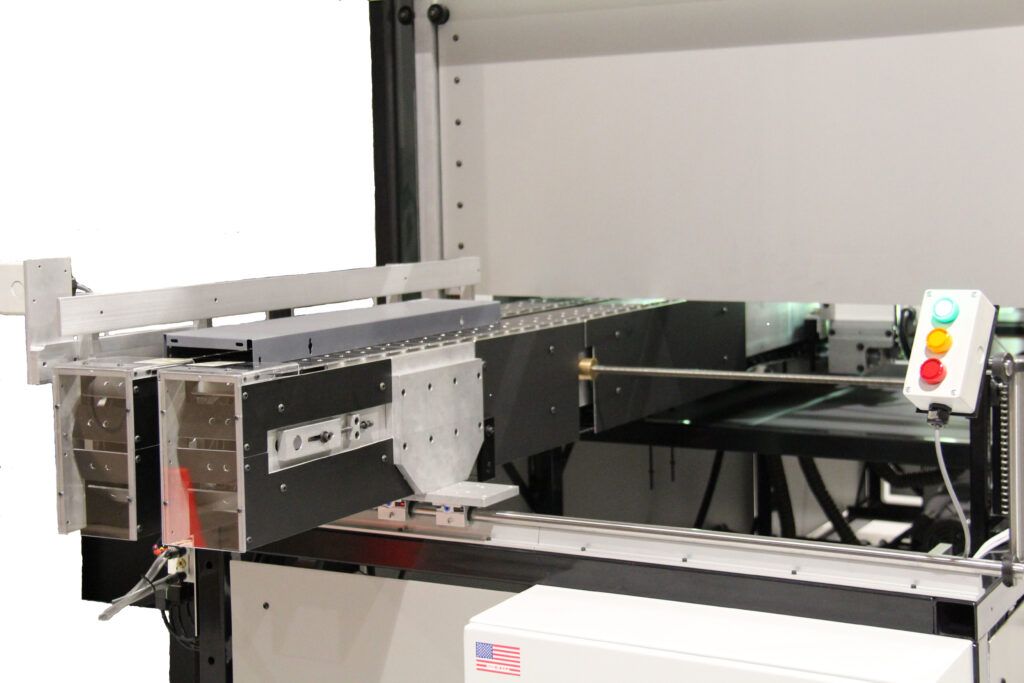

Systematic automation has engineered a conveyor for your heavy parts such as boxes / cabinets that require dual UV curing on the right and left of your product. Rather curing your product again, both sides are cured simultaneously. The UV light is covered by the shutter system when your product is not in the UV chamber.

The UV Conveyor Max is designed for heavy & large products. Irradiators (lamps) are placed vertically on each side of the product. Both have the capacity for a maximum output of 400 WPI. Sensors are installed for safety precautions and to automate your curing process.

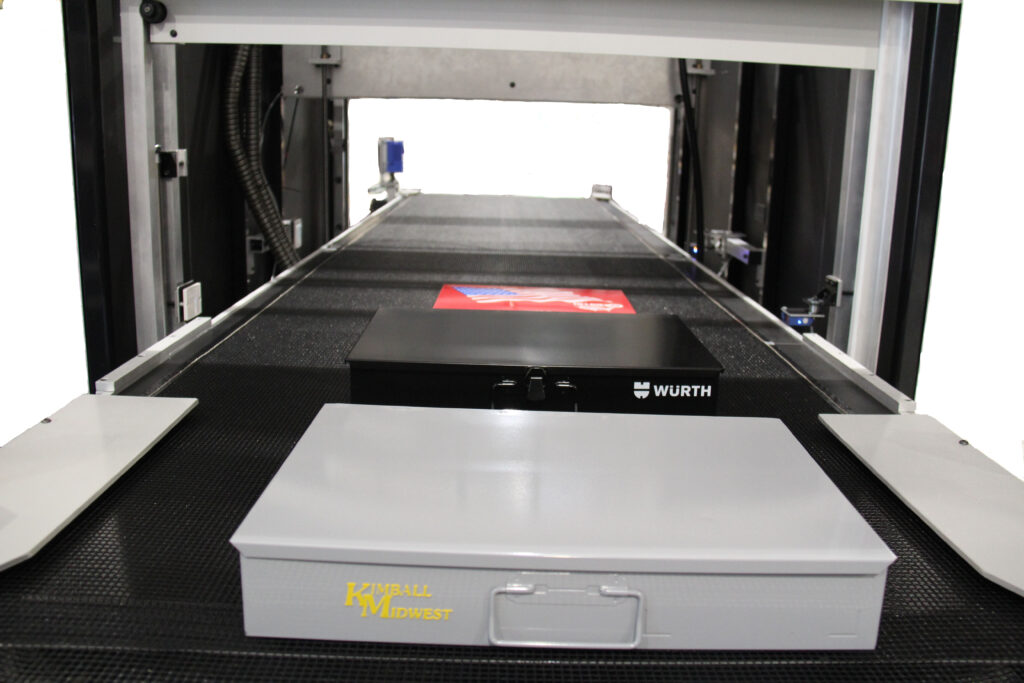

Once the product is placed on the conveyor, it is sensed and the door to the chamber opens, once closed, the shutters open for light exposure. After the curing cycle is complete (adjustable), the shutters will close and the door will open for your finished product to move through followed by it being stopped by a sensor at the end of the conveyor. The Sensor placement is adjustable incase you have a product that deviates in size from your others.

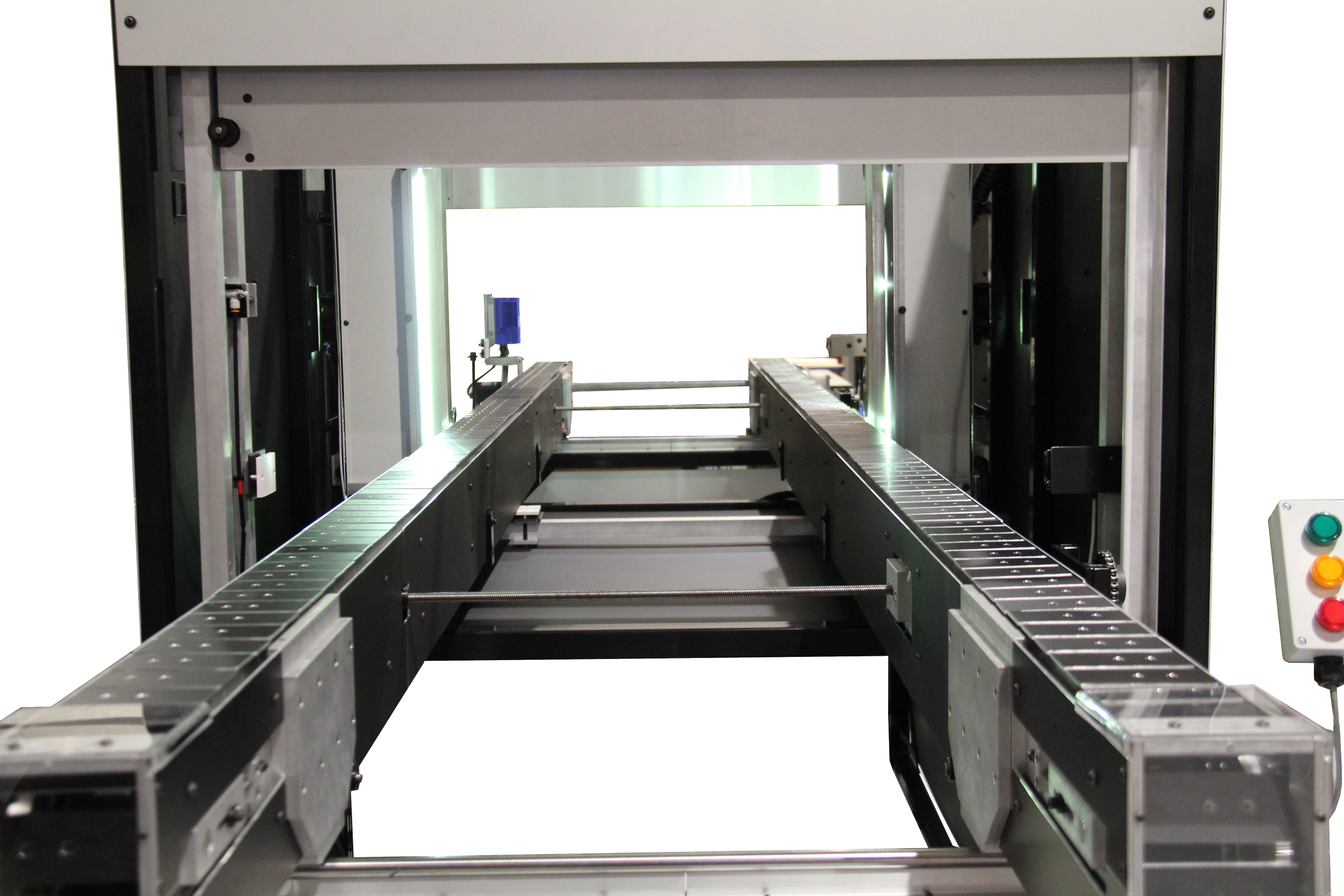

The MAX Conveyor may utilize a traditional mesh belt or an aluminum plated belt. For the aluminum plated belt, two belts are utilized to cary the weight of your product. Both of the conveyor belt tracks on the MAX Conveyor use aluminum plates for transport rather than a typical mesh belt you will find on conventional conveyors. The new aluminum belting will provide reliability and support the weight out of your product without the possibility of tearing a standard mesh belt. If you are changing the size of the product you are curing, use the wheel handle to easily adjust the conveyor to the new product size. The lamp fixture is attached to the belt to maintain an optimal UV focal point.

The UltraLight System is used on all UV conveyors unless otherwise specified. The focal point of each irradiator focuses the light for maximum UV exposure. The UltraLight is a tri-power system (200/300/400 WPI) with a programmable logic controller (PLC) for integration with existing equipment. The power supply uses continuous monitoring of the irradiator cooling blower and temperature sensor inside the power supply for thermal component protection.

UV lamp irradiators may be replaced with LED modules.